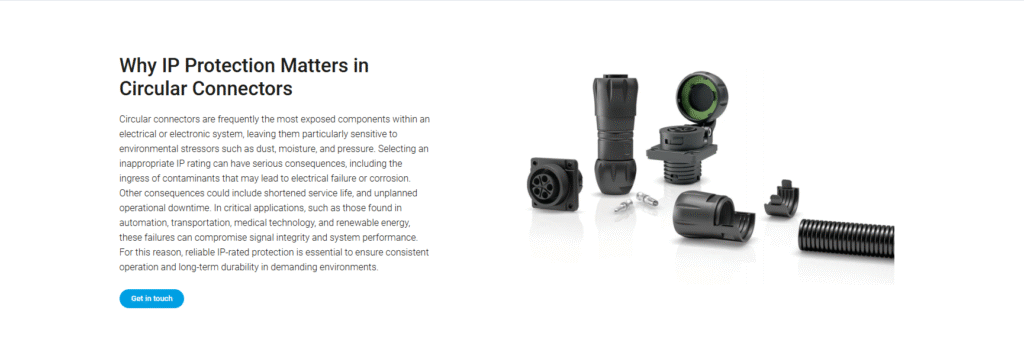

Ever struggled with electrical connections failing in wet conditions? You need waterproof connectors that actually survive German weather, industrial cleaning, and harsh environments.

Germany leads waterproof connector manufacturing, with companies like Wieland Electric, Phoenix Contact, and HARTING dominating the market. These manufacturers produce IP67-IP69 K-rated connectors for industrial automation, outdoor lighting, and food processing. Their products withstand water jets, chemical exposure, and extreme temperatures while maintaining reliable electrical connections.

Finding the right waterproof connector manufacturer saves you from costly equipment failures and production downtime. I’ve worked with most of these German manufacturers over my 15 years in this industry, so I’ve compiled this comprehensive guide to help you better evaluate and find suitable connector suppliers. This guide provides value in product quality assessment, cost optimization, and technical support comparison.

In the following article, I’ll analyze these manufacturers from several key perspectives: discovering which German manufacturers produce the most reliable IP68 connectors for extreme environments, understanding what makes Phoenix Contact stand out with their €2.8 billion market dominance, learning how Wieland Electric’s unique sealing technology ensures food-safe connections, exploring why engineers trust HARTING for critical outdoor installations, identifying which specialized manufacturers like Binder excel in circular connector technology, revealing how smaller Mittelstand companies compete through customization and flexibility, understanding how German DIN standards shape global connector requirements, providing practical selection criteria to avoid costly specification mistakes, and finally presenting the complete top 10 manufacturer rankings for 2025. This comprehensive analysis helps you understand each manufacturer’s core competencies, market positioning, and unique value propositions.

Which German manufacturers produce the most reliable IP68 connectors?

Dealing with water damage in electrical systems costs thousands in repairs. German manufacturers have perfected waterproof connector technology through decades of engineering excellence.

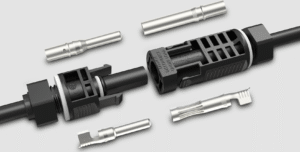

The most reliable IP68 connector manufacturers in Germany include Wieland Electric with their RST® series, Phoenix Contact’s M12/M23 industrial connectors, and HARTING’s Han® series. These companies test their IP68 connectors at depths beyond 2 meters for 24+ hours, exceeding standard requirements. Their connectors feature individual contact sealing, corrosion-resistant materials, and mechanical coding to prevent installation errors.

Understanding IP68 Certification Standards

German manufacturers follow strict DIN 40050-9 standards for waterproof ratings. Unlike basic IP67 connectors that handle temporary submersion, IP68 connectors from German manufacturers undergo extreme testing protocols.

| Protection Level | Test Conditions | German Standard | Typical Applications |

|---|---|---|---|

| IP67 | 1m depth, 30 minutes | DIN EN 60529 | Outdoor lighting, sensors |

| IP68 | 2m+ depth, 24 hours | DIN 40050-9 | Underwater equipment, marine |

| IP69K | High-pressure jets, 80°C | DIN 40050-9 | Food processing, washdown |

Leading manufacturers like Wieland test their connectors at 3 meters for extended periods. HARTING goes further by testing mechanical stress alongside water ingress. This ensures that connectors maintain performance even when cables experience movement underwater.

What makes Phoenix Contact stand out among waterproof connector suppliers?

Phoenix Contact frustrates competitors by capturing over 30% of Germany’s industrial automation connector market. Their dominance comes from solving real industrial problems.

Phoenix Contact excels through its COMBICON connection system that combines IP65/IP67/IP68 protection with tool-free installation. Their M12 and M23 circular connectors feature gold-plated contacts resisting corrosion while liquid crystal polymer housings maintain stability across -40°C to +125°C. With 50 subsidiaries worldwide and €2.8 billion in revenue, they provide local support that smaller manufacturers cannot match.

Phoenix Contact’s Industrial Innovation

I’ve installed Phoenix Contact connectors in chemical plants where ordinary connectors dissolve within weeks. Their special material formulations resist oils, coolants, and cleaning chemicals that destroy standard connectors.

Key Phoenix Contact Technologies:

- QUICKON fast-connection – Reduces installation time by 50%

- HEAVYCON modular system – Combines power and data in one connector

- PLUSCON redundant contacts – Maintains connection even if contacts wear out

Phoenix Contact’s German engineering shows in details like their push-in spring connections that eliminate loose wires. Their connectors include integrated strain reliefs, preventing cable damage. Every design choice reflects feedback from industrial users facing real-world challenges.

How does Wieland Electric ensure waterproof connections in food processing?

Food industry regulations destroy most connector manufacturers’ products. Wieland Electric thrives where others fail through specialized design approaches.

Wieland Electric’s RST® connectors achieve an IP69K rating through unique longitudinal sealing technology, where each contact has individual seals preventing water migration through cables. Their food-grade materials withstand daily high-pressure washdowns with 80°C water and aggressive sanitizers. The mechanical coding system with 20+ color options prevents cross-contamination between production lines, while smooth surfaces eliminate bacterial growth points.

Advanced Sealing Technologies

Wieland revolutionized waterproof connectors by addressing capillary action – water traveling inside cables. Traditional connectors only seal the connection point, but water enters through the cable ends during temperature changes.

Wieland’s Multi-Barrier Approach:

- Primary housing seal (IP68/IP69K rated)

- Individual contact seals (prevent water migration)

- Cable gland compression (blocks cable entry)

- Barrier seal option (protects unmated connectors)

Their RST® POWER series handles 53A at 600V while maintaining IP68 protection. I’ve seen these connectors survive submersion in food-grade cleaning solutions that corrode standard industrial connectors within hours.

Why do engineers choose HARTING for outdoor electrical connections?

Outdoor installations punish connectors through temperature swings, UV exposure, and weather extremes. HARTING dominates this market through 75 years of connector evolution.

Engineers select HARTING for outdoor applications because their Han® series connectors combine IP65/IP67 ratings with -40°C to +200°C temperature resistance. The hoods use special UV-stabilized materials preventing degradation while their PushPull mechanism enables connection without tools, even when wearing thick gloves. HARTING’s modular system allows mixing power, signal, and data contacts in one compact connector, reducing installation points by 60%.

Extreme Environment Performance

HARTING’s German headquarters in Espelkamp tests connectors in conditions simulating 20-year outdoor exposure. Their accelerated aging chambers cycle between -60°C and +150°C with UV bombardment and salt spray.

| Environmental Test | HARTING Standard | Industry Standard | Real-World Benefit |

|---|---|---|---|

| Temperature cycling | 1000 cycles | 500 cycles | 20+ year lifespan |

| Salt fog exposure | 1000 hours | 500 hours | Marine/coastal use |

| Vibration resistance | 50g acceleration | 25g standard | Heavy machinery compatible |

| Mating cycles | 10,000+ | 5,000 typical | Reduced maintenance |

The Han® F+B series specifically targets food and beverage applications with FDA-approved materials. Their large radiused surfaces meet EHEDG hygiene standards while maintaining IP69K protection during high-pressure cleaning.

Which specialized German manufacturers focus on circular waterproof connectors?

Circular connectors require precision manufacturing that few companies master. German specialists dominate through advanced machining capabilities.

Binder leads Germany’s circular waterproof connector market with their 600+ series portfolio, ranging from 6mm miniature to 44mm industrial sizes. Based in Neckarsulm since 1960, they produce IP67/IP68/IP69K connectors using automated CNC manufacturing, ensuring consistent quality. Their M12 connectors with L/T-coding and stainless steel locking serve automation, while their NCC (Not Connected Closed) technology provides IP67 protection even when unmated.

Precision German Engineering

Binder’s 2,000 employees focus exclusively on circular connectors, allowing for specialization that is impossible for broader manufacturers. Their Innovation Center in Neckarsulm develops custom solutions for unique applications.

Binder’s Specialized Series:

- 620/720 Series – Snap-in waterproof to IP67

- 693 Series – VDE certified for medical equipment

- 770 Series NCC – Protected when unmated

- 713 Stainless – Chemical resistant IP69K

My experience with Binder shows their strength in customization. They modified their 713 series for a brewery application, creating acid-resistant connectors that survive daily sanitization. This customer focus distinguishes German manufacturers from mass-market competitors.

How do smaller German manufacturers compete in the waterproof connector market?

Large corporations dominate headlines, but Germany’s Mittelstand companies drive innovation through specialization. These focused manufacturers solve problems that giants ignore.

Smaller German manufacturers like Franz Binder, Hummel, and GES compete through ultra-specialization in niche waterproof applications. They offer faster customization, lower minimum orders, and direct engineering support. Companies like Lumberg Automation focus on specific markets like 7/8″ automation connectors, achieving expertise that larger manufacturers cannot match. Their family ownership enables 20+ year customer relationships and application-specific development.

The Mittelstand Advantage

German family-owned connector companies operate differently from corporations. I’ve worked with Hummel on custom connectors where their engineer visited our facility, understood our exact needs, and delivered prototypes in weeks, not months.

Mittelstand Manufacturer Strengths:

- Application expertise – Deep knowledge in specific industries

- Rapid prototyping – 2-4 week custom samples

- Flexible quantities – Economic batches from 100 pieces

- Direct support – Engineer-to-engineer communication

- Long-term focus – Solutions lasting decades

These manufacturers often supply connectors to machine builders creating specialized equipment. When you need 200 custom connectors for a unique application, they deliver where giants demand 10,000-piece minimums.

How do German standards influence global waterproof connector design?

German industrial standards set global benchmarks. DIN standards often become ISO standards, spreading German engineering worldwide.

German DIN and VDE standards influence global waterproof connector design by establishing testing protocols adopted internationally. DIN 40050-9, defining IP69K protection, became the worldwide standard for high-pressure washdown resistance. German manufacturers’ participation in IEC committees ensures that their practical experience shapes international standards. This standardization benefits users through consistent quality expectations and interchangeable components across manufacturers.

From German Standard to Global Practice

I’ve watched German standards transform international manufacturing. When DIN 40050-9 introduced IP69K ratings, it solved food industry problems globally. Now, manufacturers worldwide follow German-developed testing procedures.

German Standards’ Global Impact:

- IEC 61076 – Industrial connectors (German-led development)

- IEC 60529 – IP protection codes (incorporated DIN standards)

- EN 45545 – Railway fire protection (German rail requirements)

- ISO 14001 – Environmental systems (German manufacturing practices)

German manufacturers actively participate in standards development, ensuring real-world experience guides specifications. This involvement maintains Germany’s technical leadership while helping global manufacturers improve quality.

What factors should I consider when selecting German waterproof connectors?

Choosing the wrong connectors causes field failures, warranty claims, and a damaged reputation. German manufacturers offer solutions, but selection requires careful analysis.

Selecting German waterproof connectors requires evaluating the IP rating for your environment, temperature range, chemical exposure, mating cycles, and installation method. Consider the total cost, including installation time, not just component price. German manufacturers provide detailed selection guides, but key factors include: conductor size/quantity, voltage/current requirements, mechanical stress, and regulatory compliance. Request samples for testing before volume purchases.

Essential Selection Criteria

Based on my experience working with hundreds of connector applications, here’s a comprehensive framework to guide your selection process:

Essential Selection Criteria:

- Environmental Requirements

- Water exposure type (splash, spray, submersion)

- Temperature extremes (-40°C to +125°C typical)

- Chemical/cleaning agent exposure

- UV and weather resistance needs

- Electrical Specifications

- Voltage rating (24V to 600V common)

- Current capacity (consider derating)

- Signal integrity requirements

- Shielding needs (EMI/RFI)

- Mechanical Considerations

- Mating cycles (500 to 10,000+)

- Cable flexibility requirements

- Vibration/shock resistance

- Installation space constraints

- Compliance Requirements

- Industry standards (IEC, DIN, UL)

- Application regulations (food, medical)

- Environmental directives (RoHS, REACH)

- Safety certifications needed

German manufacturers provide exceptional pre-sales engineering support. They’ll review your application, suggest optimal solutions, and provide test samples. This technical partnership distinguishes them from purely price-focused suppliers.

Which German waterproof connector manufacturers will lead in 2025?

After researching the market and drawing from my direct experience with these manufacturers, here are Germany’s top 10 waterproof connector manufacturers for 2025.

Germany’s top waterproof connector manufacturers for 2025 include Wieland Electric, Phoenix Contact, HARTING, Binder, Weidmüller, Hummel, Ilme, Fischer Connectors, Lapp Group, and AGX Connector. These companies combine traditional German engineering with innovative technologies like smart connectivity and advanced sealing. They serve industries from automation to renewable energy with IP67-IP69 K-rated solutions.

The Top 10 German Manufacturers

1. Wieland Electric

| Company Name | Wieland Electric |

|---|---|

| Founded | 1910 |

| Website | https://www.wieland-electric.com/ |

| Headquarters | Bamberg, Germany |

| Main Business | Electrical connection technology, pluggable installation systems, safety technology |

| Key Products | RST® connectors, gesis® connectors, industrial connectors, terminal blocks |

| Specialty | Electrical connection technology, pluggable installation systems, and safety technology |

| Value Advantage | Market leader in pluggable installation technology with 100+ years experience |

Overview: Wieland Electric is a century-old German company that pioneered electrical connection technology. They are the world market leader for pluggable installations in building technology, serving over 70 countries with production facilities in Germany, the Czech Republic, and China. Their RST® series offers IP69K protection specifically designed for food industry applications with individual contact sealing technology.

2. Phoenix Contact

| Company Name | Phoenix Contact |

|---|---|

| Founded | 1923 |

| Website | https://www.phoenixcontact.com/ |

| Headquarters | Blomberg, North Rhine-Westphalia, Germany |

| Main Business | Industrial automation, electrical connections, electronic interfaces |

| Key Products | M12/M23 connectors, COMBICON system, QUICKON connectors |

| Specialty | Industrial automation connectivity solutions |

| Value Advantage | €2.8 billion revenue with 50 subsidiaries worldwide |

Overview: Phoenix Contact stands as a global leader in electrical connections with nearly 100 years of expertise. They excel in industrial automation markets through innovative solutions like tool-free COMBICON systems and maintain dominance with over 30% market share in Germany’s industrial automation connector sector. Their 12,000+ employees worldwide ensure comprehensive customer support.

3. HARTING

| Company Name | HARTING Technology Group |

|---|---|

| Founded | 1945 |

| Website | https://www.harting.com/ |

| Headquarters | Espelkamp, Germany |

| Main Business | Industrial connectors, Ethernet solutions, and electronic components |

| Key Products | Han® modular connectors, ix Industrial®, PushPull connectors |

| Specialty | Heavy-duty modular connector systems |

| Value Advantage | Industrial connectors, Ethernet solutions, electronic components |

Overview: HARTING has established itself as a pioneer in industrial connectivity since 1945. Known for their robust Han® modular connector series, they serve demanding applications in machinery, wind power, and the railway industries. Their innovative PushPull technology and smart connectivity solutions position them at the forefront of Industry 4.0 developments.

4. Binder

| Company Name | Franz Binder GmbH & Co. |

|---|---|

| Founded | 1960 |

| Website | https://www.binder-connector.com/ |

| Headquarters | Neckarsulm, Germany |

| Main Business | Circular connectors for industrial and automation technology |

| Key Products | M12 connectors, 600+ circular connector series, NCC connectors |

| Specialty | Miniature to multi-pole circular connectors (6mm to 44mm) |

| Value Advantage | 2,000 employees focused exclusively on circular connectors |

Overview: Binder represents German Mittelstand excellence with over 60 years of specialization exclusively in circular connectors. As a family-owned company, they offer unmatched expertise in circular connector technology with their extensive portfolio of 600+ series. Their NCC (Not Connected Closed) technology provides unique IP67 protection even when connectors are unmated.

5. Weidmüller

| Company Name | Weidmüller Group |

|---|---|

| Founded | 1850 |

| Website | https://www.weidmueller.com/ |

| Headquarters | Detmold, Germany |

| Main Business | Industrial connectivity and automation solutions |

| Key Products | Terminal blocks, industrial connectors, automation technology |

| Specialty | Push-in connection technology |

| Value Advantage | 170+ years of experience in electrical connectivity |

Overview: Weidmüller brings over 170 years of German engineering excellence to industrial connectivity. They specialize in terminal technology and connection solutions for process industries, offering innovative push-in connections that reduce installation time. Their comprehensive portfolio serves automation, energy, and process industries worldwide.

6. Hummel

| Company Name | HUMMEL AG |

|---|---|

| Founded | 1946 |

| Website | https://www.hummel.com/ |

| Headquarters | Denzlingen, Germany |

| Main Business | Cable glands, connectors, and cable protection systems |

| Key Products | M12 connectors, cable glands, industrial connectors |

| Specialty | Custom connector solutions and cable entry systems |

| Value Advantage | ATEX and IECEx certified solutions for hazardous areas |

Overview: Hummel AG specializes in connection technology with particular strength in cable glands and custom solutions. As a family-owned Mittelstand company, they offer exceptional flexibility in developing application-specific products with rapid prototyping capabilities. Their expertise in hazardous area applications makes them a preferred partner for chemical and process industries.

7. GES

| Company Name | GES GmbH |

|---|---|

| Founded | 1956 |

| Website | https://www.ges-highvoltage.com/ |

| Headquarters | Germany |

| Main Business | High-voltage connectors and cable systems |

| Key Products | High-voltage connectors, cable assemblies, testing equipment |

| Specialty | High-voltage and high-current connections |

| Value Advantage | High-voltage connectors, cable assemblies, and testing equipment |

Overview: GES specializes in high-voltage connector technology serving demanding electrical applications. They provide comprehensive solutions for high-voltage and high-current requirements in industrial, energy, and testing environments. Their expertise in extreme electrical conditions makes them a trusted partner for applications where standard connectors cannot perform.

8. Fischer Connectors

| Company Name | Fischer Connectors GmbH |

|---|---|

| Founded | 1954 |

| Website | https://www.fischerconnectors.com/ |

| Headquarters | Germany (Swiss parent company) |

| Main Business | High-performance circular connectors |

| Key Products | UltiMate series, hermetic connectors, fiber optic solutions |

| Specialty | Hermetic sealing for extreme environments |

| Value Advantage | 300m depth rating for subsea applications |

Overview: Fischer Connectors combines Swiss precision with German engineering to create ultra-reliable connectivity solutions. They excel in extreme environment applications with hermetic sealing technology enabling 300-meter underwater operation. Their connectors serve critical applications in defense, medical, and subsea industries where failure is not an option.

9. FESTO

| Company Name | FESTO AG & Co. KG |

|---|---|

| Founded | 1925 |

| Website | https://www.festo.com/ |

| Headquarters | Esslingen am Neckar, Germany |

| Main Business | Industrial automation, pneumatic and electrical automation technology |

| Key Products | Automation components, connectors, sensors, control systems |

| Specialty | Pneumatic and electrical automation solutions |

| Value Advantage | Complete automation solutions with 20,000+ products |

Overview: FESTO is a global leader in industrial automation technology, offering comprehensive solutions for factory and process automation. With nearly 100 years of German engineering excellence, they provide innovative connectivity solutions as part of their broader automation portfolio. Their expertise in both pneumatic and electrical systems enables integrated solutions for complex industrial applications, serving over 300,000 customers in 176 countries.

10. AGX Connector

| Company Name | AGX Connector |

|---|---|

| Founded | 2016 |

| Website | https://agxconnector.com/ |

| Headquarters | China (Serving German and European markets) |

| Main Business | Waterproof connectors and cable assemblies |

| Key Products | IP68 waterproof connectors for lighting and industrial, MC4 solar connector, Energy storage connector, cable gland, push wire connector, cable gland |

| Specialty | Cost-effective waterproof connectivity solutions |

| Value Advantage | 15 years specialized experience with global distribution |

Overview: AGX Connector brings 15 years of focused expertise in waterproof connector manufacturing. Founded by Cindy Lee, who has extensive experience in the waterproof connector industry, AGX provides knowledge-sharing and cost-effective solutions for distributors worldwide. They specialize in making waterproof connector technology accessible while maintaining quality standards that meet German market requirements.

Comparison of Top 10 German Waterproof Connector Manufacturers

| Rank | Company | Founded | IP Rating | Key Specialty | Main Industries |

|---|---|---|---|---|---|

| 1 | Wieland Electric | 1910 | IP67/68/69K | RST® plug-and-play systems | Food & Beverage, Building Technology |

| 2 | Phoenix Contact | 1923 | IP65/67/68 | Tool-free COMBICON | Industrial Automation |

| 3 | HARTING | 1945 | IP65/67 | Han® modular systems | Railway, Wind Energy |

| 4 | Binder | 1960 | IP67/68/69K | Circular connectors (6-44mm) | Automation, Medical |

| 5 | Weidmüller | 1850 | IP65/67 | Push-in connections | Process Industry |

| 6 | Hummel | 1946 | IP66/67/68 | Custom solutions, ATEX | Chemical, Hazardous Areas |

| 7 | GES | 1956 | IP65/67 | High-voltage connectors | Energy, Testing |

| 8 | Fischer Connectors | 1954 | IP68 (300m) | Hermetic sealing | Subsea, Defense |

| 9 | FESTO | 1925 | IP65/67 | Automation components | Factory Automation |

| 10 | AGX Connector | 2010 | IP67/68/69K | Cost-effective solutions | Global Distribution |

Key Features Comparison:

- Heritage: 5 companies with 75+ years of experience

- Protection: All offer minimum IP67, with 6 offering IP69K

- Specialization: From food-grade to subsea applications

- Global Reach: Combined presence in 150+ countries

Conclusion

This comprehensive guide offers essential insights into Germany’s top waterproof connector manufacturers, enabling you to make informed sourcing decisions that reduce failure rates, minimize downtime costs, and ensure long-term reliability. By understanding each manufacturer’s strengths – from Wieland’s food-safe IP69K solutions to HARTING’s extreme weather resistance – you can select connectors that match your specific application requirements.

The value of working with German manufacturers extends beyond product quality. You gain access to century-old engineering expertise, comprehensive technical support, and proven solutions that have been tested in the world’s most demanding industrial environments. Whether you need Phoenix Contact’s tool-free installation systems or Binder’s specialized circular connectors, this guide helps you identify the right partner for your needs.

As an experienced manufacturer of waterproof connectors ourselves, AGX Connector understands the challenges distributors face when selecting reliable suppliers. We combine the quality standards expected in German markets with competitive pricing, flexible minimum orders, and dedicated customer support. Our 15 years of specialized experience mean we can help you navigate product selection, provide technical guidance, and ensure your waterproof connector needs are met efficiently. Visit agxconnector.com to learn how we can support your business growth with reliable waterproof connectivity solutions.

My Story with German Connectors

I remember my first encounter with German waterproof connectors. One of my customers, who’s also a good friend, manages a food processing plant. He told me their connectors kept failing repeatedly. The connectors couldn’t handle daily washdowns with 80°C sanitizer. I recommended Wieland RST® connectors – they cost three times more but lasted five years without failure. That experience taught me the real cost isn’t the connector price, it’s the downtime when connections fail. German manufacturers understand this, designing products that survive where others surrender. Today, I specify German connectors for any application where failure isn’t acceptable. The initial investment pays back through reliability that keeps production running.