Professional Electrical Waterproof Connectors Manufacturer

Ultimate all-in-one solution for reliable electrical connections in harsh environments.

Find all the waterproof connectors you need right here.

- Official supplier to 50+ international brands

- 12+ years electrical connector expertise

- Serving distributors in 47+ countries worldwide

- Complete OEM & ODM design services

- CE • TUV • UL • SAA • ISO certified

- Maximum quality at competitive factory pricing

3,000,000+

Units Produced

Trusted Volume You Can Count On

6,300 m²

Modern Factory

Complete In-House Manufacturing Control

12+ Years

Industry Experience

Proven Expertise in Every Connector

20+

Patented Innovations

Exclusive Technology Others Can't Copy

Wholesale Electrical Connectors

Our Products

Waterproof

Cable Gland >

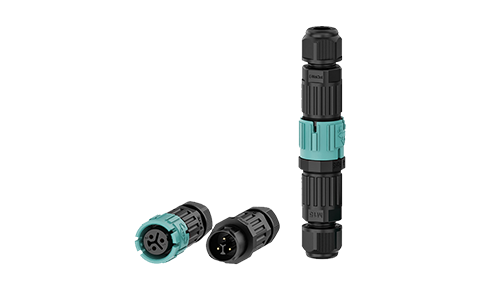

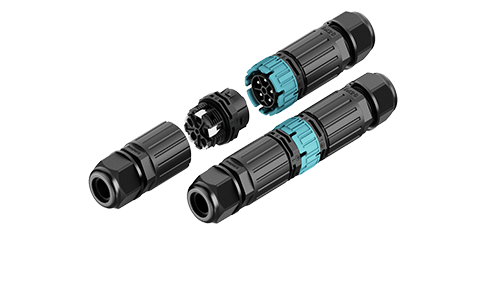

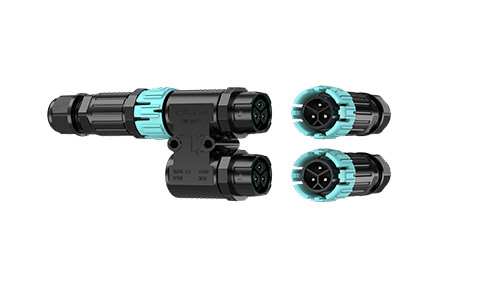

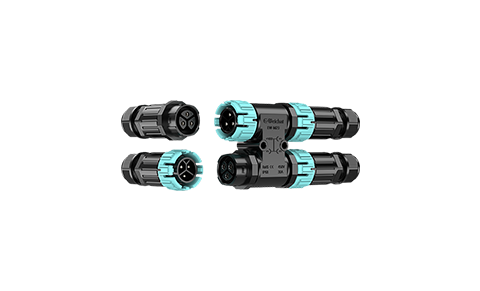

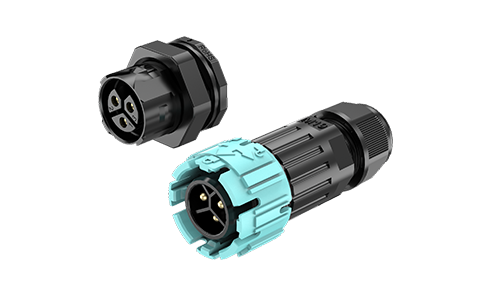

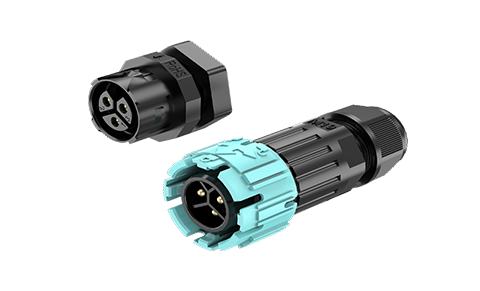

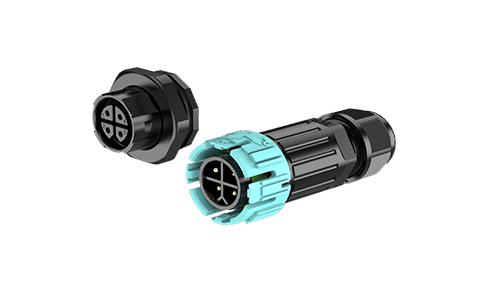

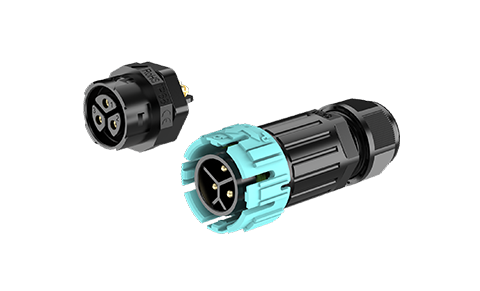

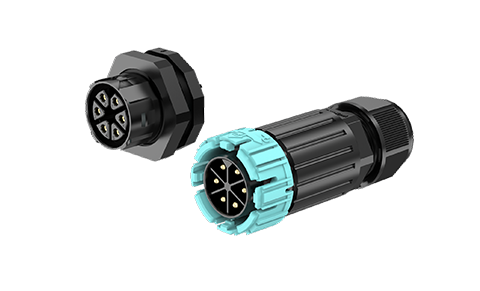

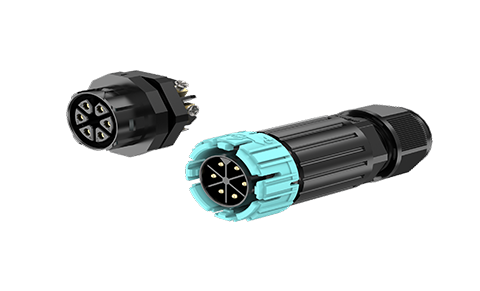

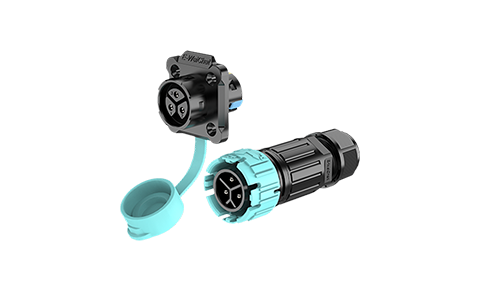

Screw-Free Waterproof Connector

Model No.: EW-P20-2P/3P

Model No.: EW-P25-4P / 5P

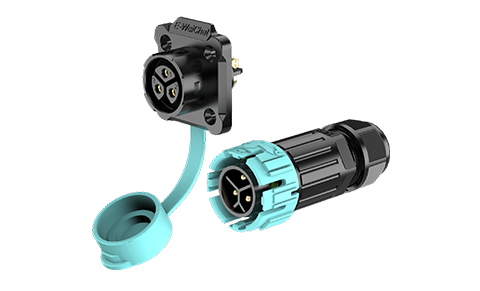

Model No.:EW-M25B-2P / 3P

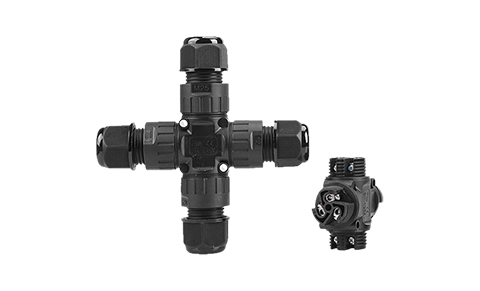

Model NO.: EW-P20T-2P / 3P

Model NO.: EW-P20T-B02

Model NO.: EW-P20X-2P

Model NO.: EW-P25T-B03

Model NO.: EW-P25X- 3P

Specification Download

Model No.

Type

Specification.PDF

Screw Waterproof Connector

Model No: EW-M16-2P/3P

Model No: EW-M20-2P/3P/4P/5P/6P

Model No: EW-M25-2P /3P/4P/5P

Model No: EW-M25-3T/4T/5T-3P/4P/5P

Model No: EW-M20T-2P/3P/4P

Model No: EW-M25T-2P/3P

Model No: EW-M20X-2P/3P

Model No: EW-M25X-2P/3P

Model No: EW-M25I-2P/3P/4P/5P

Model No: EW-M25TC-2P/3P/4P/5P

Model No: EW-M25Y-2P/3P/4P/5P

Specification Download

Model No.

Type

Specification.PDF

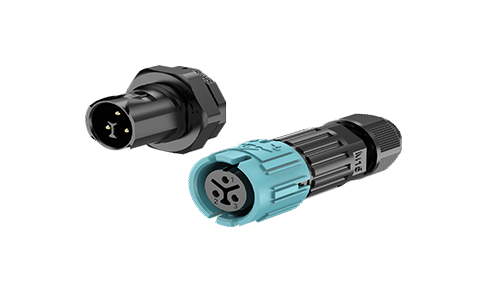

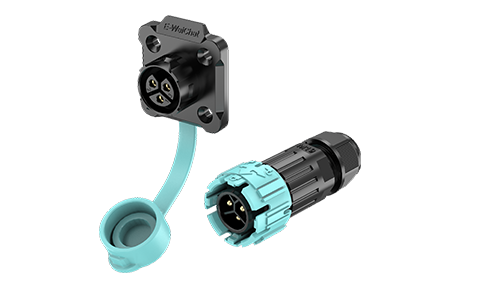

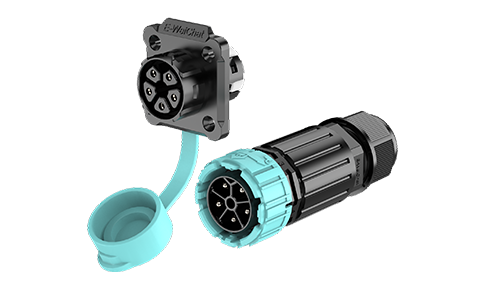

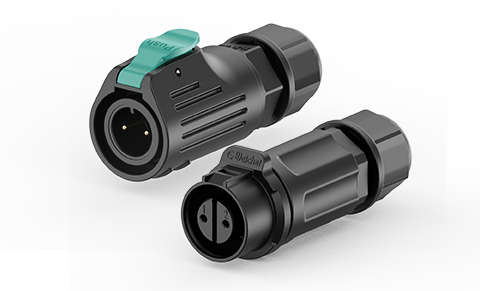

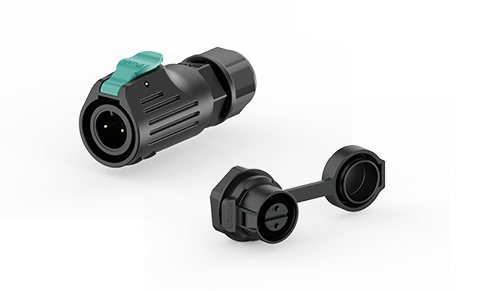

Plug Socket Waterproof Connectors

Model No: EW-M15MF-XP

Model No: EW-M19MF-XP

Model No: EW-M23MF-XP

Model No: EW-M28MF-XP

Model No: EW-P23MF-XP

Model No: EW-P25MF-XP

Model No: EW-M23MF-Y-3P

Model No: EW-M23MF-T-3P

Model No: EW-M23MF-H-3P

Model No: EW-M15MP-3P (Flange)

Model No: EW-M15MP-XP (Front Panel Mount)

Model No: EW-M19MP-3P (Flange)

Model No: EW-M19MP-XP (Front Panel Mount)

Model No: EW-M19MP-XP (Rear Panel Mount)

EW-M23MP-3P (Flange)

Model No: EW-M23MP-XP (Front Panel Mount)

Model No: EW-M23MP-XP (Rear Panel Mount)

Model No: EW-M28MP-3P (Flange)

Model No: EW-M28MP-XP (Front Panel Mount)

Model No: EW-M28MP-XP (Rear Panel Mount)

Model No: EW-P23MP-3P (Flange)

Model No: EW-P25MP-5P (Flange)

Specification Download

Model No.

Type

Specification.PDF

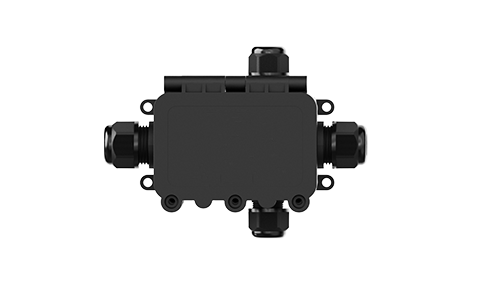

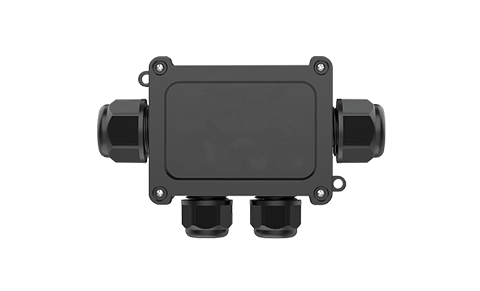

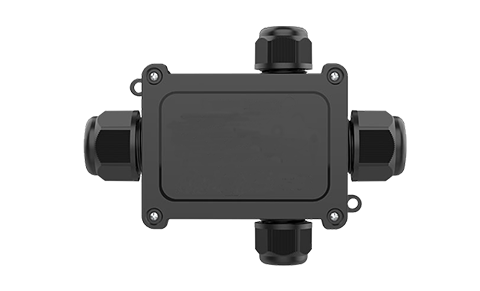

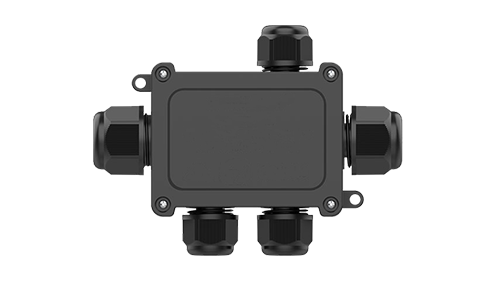

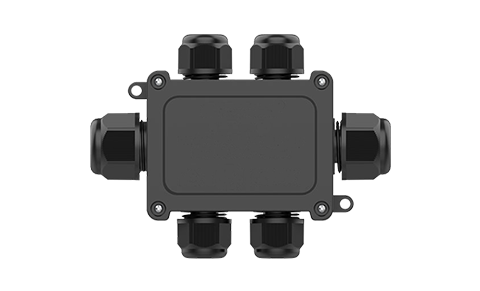

Waterproof Junction Box

Model No: EW-M2068-2T

Model No: EW-M2068-3T

Model No: EW-M2068-4TA

Model No: EW-M2068-4TB

Model No: EW-M2068-5T

Model No: EW-M2068-6T

Model No: EW-M2068S-2T

Model No: EW-M2068S-3T

Model No: EW-M2068S-4TA

Model No: EW-M2068S-4TB

Model No: EW-M2068S-5T

Model No: EW-M2068S-6T

Model No: EW-M2068L-3T

Model No: EW-M2068L-3Y

Model No: EW-M2068L-4H

Model No: EW-M2068XL-0T

Model No: EW-M2068XL-4T

Model No: EW-M2068XL-10T

Specification Download

Model No.

Type

Specification.PDF

Industrial Waterproof Connectors(LP Series)

Model No: EW-LP12 Plastic-2P/3P/4P/5P/6P/7P/8P

Model No:EW-LP12MP-2P/3P/4P/5P/6P/7P/8P

Model No: EW-LP12MP Flange-2P/3P/4P/5P/6P/7P/8P

Model No: EW-LP12 Metal-2P/3P/4P/5P/10P/12P/19P/24P

Model No:EW-LP16 Plastic-2P/3P/4P/5P/7P/8P/9P

Model No:EW-LP16MP-2P/3P/4P/5P/7P/8P/9P

Model No:EW-LP16 Flange-2P/3P/4P/5P/7P/8P/9P

Model No:EW-LP16 Metal-2P/3P/4P/5P/7P/8P/9P

Model No: EW-LP20 Plastic-2P/3P/4P/5P/6P/7P/9P/12P/14P

Model No: EW-LP20MP-2P/3P/4P/5P/6P/7P/9P/12P/14P

Model No: EW-LP20 Flange-2P/3P/4P/5P/6P/7P/9P/12P/14P

Model No: EW-LP20 Metal-2P/3P/4P/5P/6P/7P/9P/12P/14P

Model No: EW-LP24 Plastic-2P/3P/4P/5P/10P/12P/19P/24P

Model No: EW-LP24MP-2P/3P/4P/5P/10P/12P/19P/24P

Model No: EW-LP24 Flange-2P/3P/4P/5P/10P/12P/19P/24P

Model No: EW-LP24 Metal-2P/3P/4P/5P/10P/12P/19P/24P

Model No: EW-LP28-3P/5P Power

Model No: EW-LP28-3P/5P Signal

Model No: EW-LP28MP-3P/5P

Specification Download

Model No.

Type

Specification.PDF

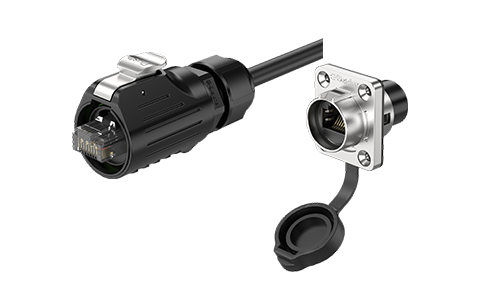

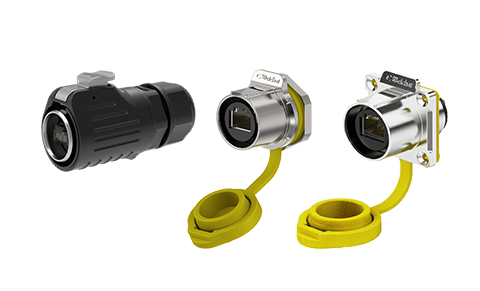

Signal Connectors

Model No: EW-LP16-RJ45

Model No:EW-LP16-RJ45 with PCB

Model No: EW-LP16-RJ45 fLANGE

Model No: EW-LP16 Type C-Plastic

Model No: EW-LP16 Type C-Metal

Model No: EW-LP24-RJ45-Metal

Model No: EW-LP24-RJ45-Plastic

Model No: EW-LP24-HDMI-Metal

Model No: EW-LP24-HDMI-Plastic

Model No: EW-LP24-Fiber

Model No: EW-LP24-Fiber-Flange

Model No: EW-LP24-Fiber-Flange

Specification Download

Model No.

Type

Specification.PDF

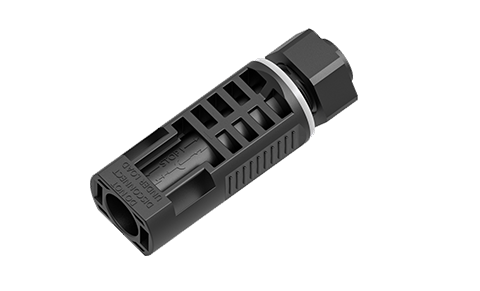

MC4 / PV4 Solar Connectors

Model No:EW-PV4F-120XX1 PV4 Cable mount female plug

Model No: EW-PV4M-121XX1 PV4 Cable mount male plug, tool unlock

Model No: EW-PV4M-122XX1 PV4 Cable mount male plug, manual unlock

Model No: EW-PV4 male & female cover

Model No: EW-PV4F-110XX1 PV4 Panle mount female plug

Model No: EW-PV4M-111XX1 PV4 Panel mount male plug, tool unlock

Model No:EW-PV4M-112XXX1 PV4 Panel mount male plug, manual unlock

Model No:EW-PV4-XXXX-PV4 Fuse

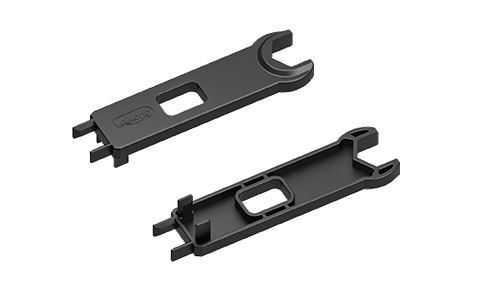

Model No:EW-PV4-Tool

Specification Download

Model No.

Type

Specification.PDF

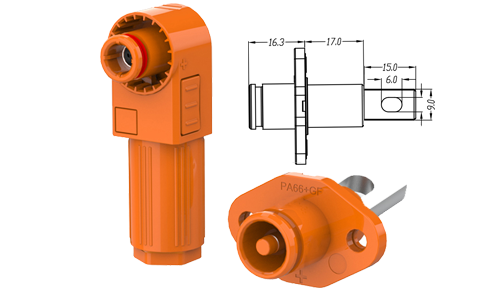

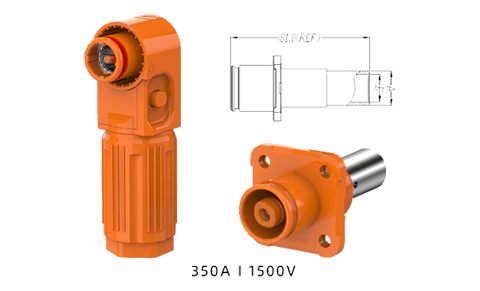

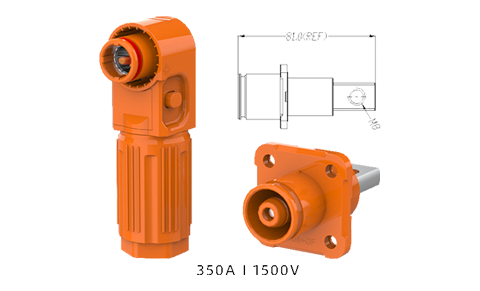

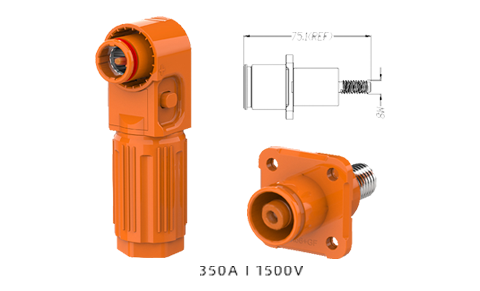

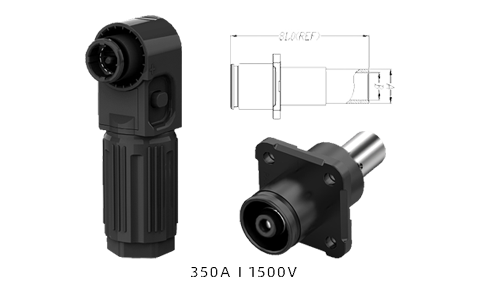

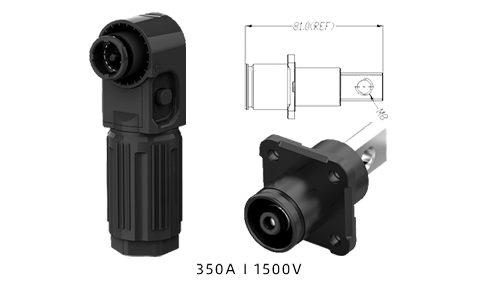

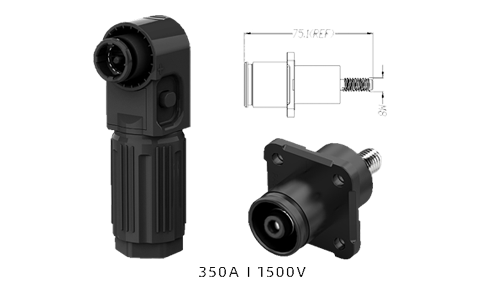

Energy Storage Connectors

Model No: EW-E50 copper bar with unthreaded hole-Orange / Black color

Model No:EW-E350 energy storage-Crimping type orange

Model No: EW-E350 Copper bar with thereaded hole-orange

Model No:E350 energy storage-Stud type orange

Model No: EW-E50 copper bar with unthreaded hole

Model No:E350 energy storage-Crimping type black

Model No:EW-E350 Copper bar with thereaded hole- black

Model No:E350 energy storage-Stud type black

Specification Download

Model No.

Type

Specification.PDF

EW-E50 / E70 / E100 / E120 / E150 / E200 / E250 / E300 / E350

Energy Storage Connector Series: 1.: 50A to 350A 2.: Colors: Orange / Black / Red

USB Waterproof Connector

Model No: EU-USB2.0 Single Interlocking Male Connector

Model No: EU-USB3.0 Single Interlocking Male Connector

Model No: EU-USB2.0 Dual Interlocking Male Connector

Model No: EU-USB3.0 Dual Interlocking Male Connector

Model No: EU-USB2.0 Cable Male to Female Cable

Model No: EU-USB3.0 Cable Male to Female Cable

Model No: EU-USB2.0 Cable Dual Female Connector

Model No: EU-USB3.0 Cable Dual Female Connector

Model No: EU-USB3.0 USB Socket

Specification Download

Model No.

Type

Specification.PDF

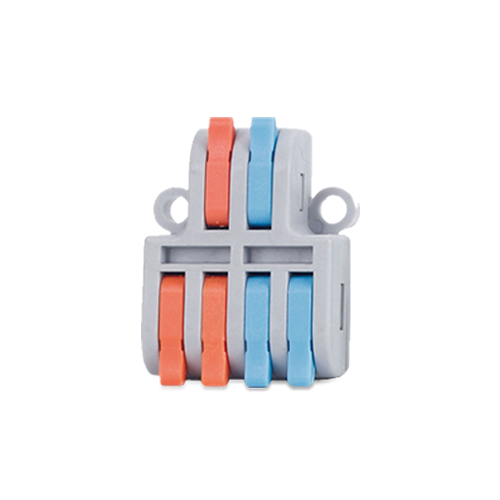

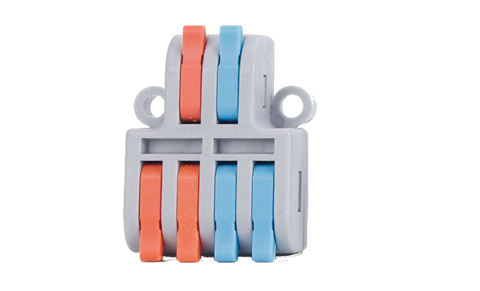

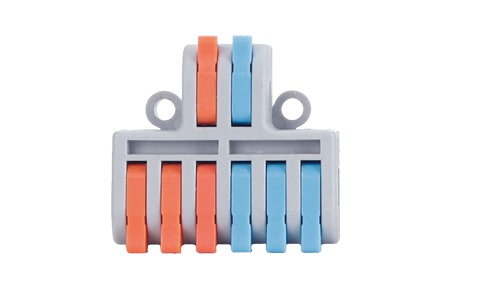

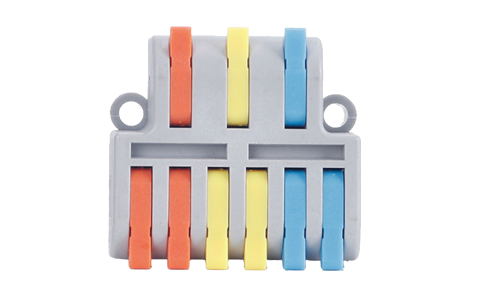

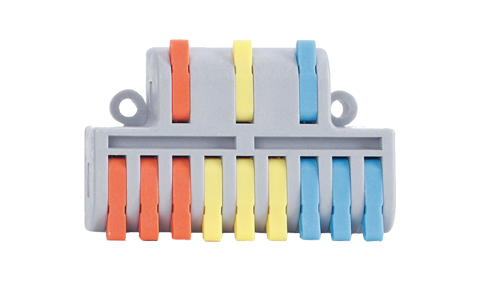

Push-Wire Connector

Model No: EW-42

Model No: EW-62

Model No: EW-63

Model No:EW-93

Model No: EW-2-2

Model No:EW-3-3

Model No:EW-4-4

Model No:EW-5-5

Specification Download

Model No.

Type

Specification.PDF

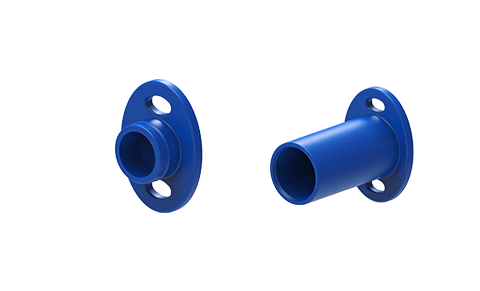

Waterproof Cable Gland

Model No: EW-M12-M40 Plastic

Model No:EW-PG7-PG48 Plastic

Model No: EW-M12-M40 Metal

Specification Download

Model No.

Type

Specification.PDF

Why Choose Our Waterproof Connection Solutions

Engineered excellence backed by manufacturing expertise. Our waterproof connectors deliver superior performance where standard connections fail.

IP68 Waterproof Protection

Ultimate water resistance for underwater and wet environments. Completely sealed against water ingress, making it perfect for marine applications, outdoor installations, and equipment that faces direct water exposure. Tested to withstand continuous submersion.

Fire & High Temperature Resistance

Superior protection in extreme heat and fire conditions. Advanced materials maintain electrical integrity even when exposed to flames and high-temperature environments. Essential for industrial applications where fire safety and heat resistance are critical.

Dust-Proof & Weather Resistance

Complete protection against dust, particles, and harsh weather. Engineered sealing prevents dust infiltration and weather damage, ensuring reliable performance in construction sites, desert environments, and outdoor industrial applications.

Screw-Less Quick Connection

Tool-free installation with secure, reliable connections. Innovative design eliminates the need for tools while maintaining strong electrical contact. Quick assembly and disassembly for maintenance without compromising connection integrity.

Waterproof

Connector Factory

Custom Electrical Waterproof Connectors

Connector Type

Straight, 90-degree, panel mount, or cable-to-cable

Based on your installation requirements

Housing Material

PA66, PBT, or specialized plastics

Chemical resistance and durability options

IP Ratings

Waterproof level required (IP65, IP67, IP68)

IP68 = complete submersion protection

Contacts/pins

Number of electrical contacts needed (2-24 pins available)

Determines how many circuits your connector can handle

Voltage Rating

Critical for safety and electrical performance

Current Rating

Maximum current per pin (5A-63A capacity)

Must match your power requirements

Cable Diameter

Wire gauge and cable outer diameter (6-20mm range)

Ensures proper strain relief and sealing

Operating Temperature

Mating Cycles

How often connectors will be plugged/unplugged

Affects contact plating and housing materials

Housing Color

Black, gray, green, or custom colors

For identification or aesthetic requirements

Marking/Labeling

Termination Style

Locking Mechanism

Electrical Connector Manufacturing Process

Our integrated 7-step production process ensures every connector meets the highest quality standards. From precision mold-making to final testing, we control every stage in-house for guaranteed reliability and fast delivery.

01

Mold Department - the foundation of everything we make

Plastic Mold Section:

These are our high-precision injection molds for connector housings, sealing rings, and insulator components. Each mold is manufactured to ±0.05mm tolerance using hardened steel that can withstand millions of injection cycles.

Hardware Mold Section:

Here we create the progressive stamping dies for our metal contacts and terminals. These molds shape brass and phosphor bronze into precise contact pins, socket terminals, and grounding components. The die design determines the spring properties and electrical performance of every contact.

02

Injection Molding Department

03

Hardware Stamping Department.

04

Automated Assembly Department

Automatic Assembly Machines:

These handle high-volume contact insertion, housing assembly, and seal installation. Each machine can assemble 2,000-3,000 pieces per hour with consistent quality.

Potting/Sealing Machines:

Our automated potting machines inject precise amounts of waterproof sealant into each connector. This creates the hermetic seal that achieves IP68 protection.

Riveting Machines:

These machines permanently secure contacts to housings using controlled force riveting, ensuring mechanical and electrical integrity that won’t degrade over time.

05

We operate 7 manual assembly production lines for customized products and quality control:

Final Assembly Stations:

Workers perform final connector assembly, cable attachment, and customization according to your specifications.

Quality Control Checkpoints:

Every 50th unit undergoes insertion force testing, visual inspection, and electrical continuity checks.

Packaging Department:

Products are packaged in anti-static bags with moisture absorbers, labeled according to your requirements, and prepared for shipment.Packaging Department: Products are packaged in anti-static bags with moisture absorbers, labeled according to your requirements, and prepared for shipment.

06

Our comprehensive testing ensures each connector will perform in real-world conditions:

- IP68 Waterproof Testing: 1.5-meter water submersion for 30 minutes minimum

- Thermal Cycling: -40°C to +105°C temperature extremes

- Electrical Performance: Insulation resistance, dielectric strength, contact resistance

- Mechanical Durability: 500+ mating cycles, vibration resistance

- Chemical Resistance: Exposure to UV, salt spray, and industrial chemicals

07

Finished Goods Warehouse and Component Storage.

Finished Goods Warehouse:

Climate-controlled storage with full traceability. Each lot is tracked from raw materials through final shipment, so we can provide complete quality documentation with every order.

Component Warehouse:

We maintain strategic inventory of contacts, housings, seals, and cables to ensure quick turnaround times. Our ERP system automatically triggers reorders to prevent production delays.

What Makes AGX Go Extra Miles

Direct Factory Pricing

Cut out the middleman with manufacturer-direct pricing on all connector solutions. Enjoy wholesale rates regardless of order size, with volume discounts available for larger projects.

Variety of Connectors

With a diverse range of high-quality connectors available: in-line circular connectors, male and female connectors, LP series device connectors, waterproof junction boxes, MC4 solar connectors, energy storage connectors, and custom solutions.

Quick Lead Time

Our stable production capacity and efficient workflows deliver samples in 1-3 days and full orders in 5-7 days. Same-day shipping available for sample orders, with even faster delivery possible based on stock levels.

OEM &ODM Service

Whatever types of Waterproof connectors you need, in-line circular connectors, male and female connectors, LPSeries devide connectors etc, in different size, configuration, and even branding, we cover it all。

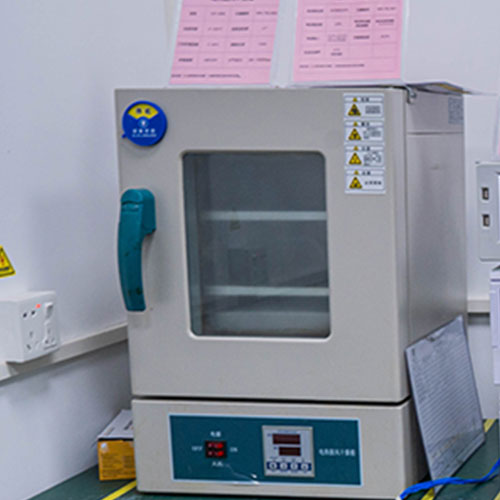

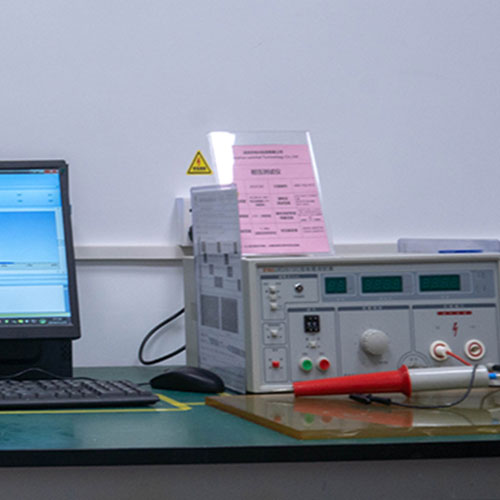

Our Laboratory

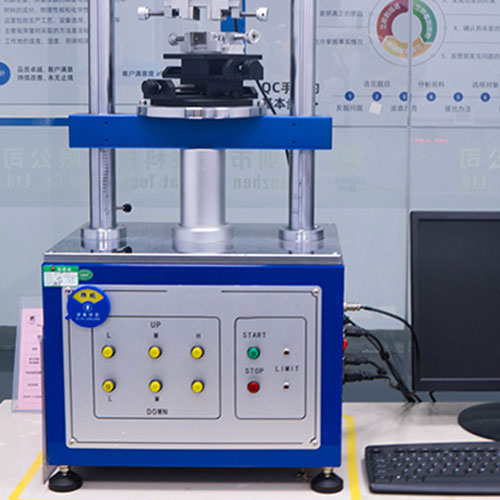

Automatic Insertion and Extraction Tester

Constant temperature and humidity tester

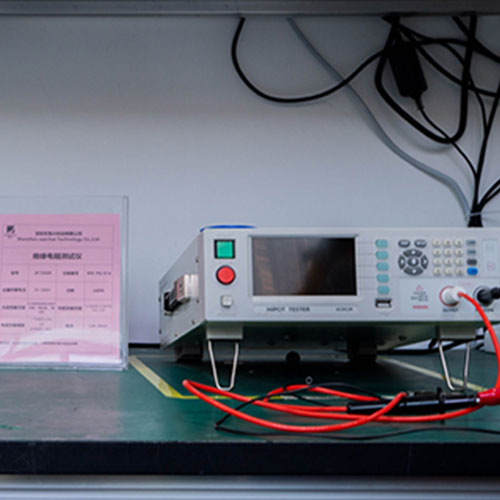

DC Resistance Insulation Resistance Tester

Electrothermal blast drying oven

Horizontal plug in test

Horizontal Vertical Flame Tester

IP68 Waterproof Tester

Leakage Trace Tester

Scorch Wire Tester

Temperature rise current tester

third dimension (math.)

Voltage Tester

Industries We Serve

From outdoor lighting to electrical components and custom applications, we provide tailored solutions to your requirements.

Automotive

Industrial

Customer Success

Solar Farm Project - Germany

Smart City Infrastructure - North America

Exhibitions & Factory Visits

AGX exhibits at premier trade shows across continents, bringing our latest waterproof connector innovations directly to global markets. Meet our experts in person to discover customized solutions that drive your projects forward.

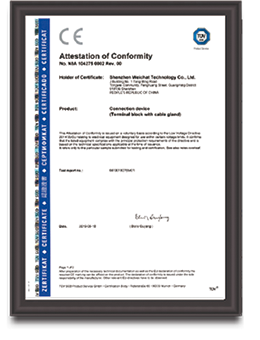

Certification & Patents

Our commitment to quality and innovation is backed by international certifications, including TÜV, UL, SAA, and CE marks that verify our products meet the highest global standards. We’ve also secured multiple European intellectual property registrations, protecting our unique connector designs while demonstrating our dedication to advancing industry technology.

Common Questions About Our Waterproof Connectors

1. How does the sterilization fuction work?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

2. How long does the deodorizing cream last?

3. How much better is the odor contrl...............?

4. How much better is the odor contrl...............?

1. Are you products suitable for pets of all sizes?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

2. How long does the deodorizing cream last?

3. How much better is the odor contrl...............?

4. How much better is the odor contrl...............?

1. Are you products suitable for pets of all sizes?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

2. How long does the deodorizing cream last?

3. How much better is the odor contrl...............?

4. How much better is the odor contrl...............?

1. Are you products suitable for pets of all sizes?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

2. How long does the deodorizing cream last?

3. How much better is the odor contrl...............?

4. How much better is the odor contrl...............?

1. Are you products suitable for pets of all sizes?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

2. How long does the deodorizing cream last?

3. How much better is the odor contrl...............?

4. How much better is the odor contrl...............?

2025 Full Waterproof Connector Catalog

- Complete technical specifications

- Quality certificates & test reports

- Integration guidelines

- Compatibility charts

Free Sample Request

Perfect for: Technical Evaluation | System Integration Testing | Quality Assessment

The Complete Beginner’s Guide to Purchasing Waterproof Connectors in 2025

Are your electrical connections failing because of water damage? Choosing the right waterproof connector can be the difference between a reliable system and costly failures. This comprehensive guide will walk you through everything you need to know about selecting, purchasing, and using waterproof connectors effectively.

What Makes a Connector “Waterproof”?

Waterproof connectors are specialized electrical connection devices designed with sealing materials like rubber gaskets and O-rings housed in durable casings to prevent water, dust, and other contaminants from reaching the electrical contacts inside. Their protection level is defined by their IP (Ingress Protection) rating, which indicates their resistance to both solid particles and liquids.

- The first number (6 in IP67/IP68) indicates complete protection against dust

- The second number (7, 8, or 9K) indicates the level of water protection:

- IP67: Protected against temporary immersion (up to 1m for 30 minutes)

- IP68: Protected against continuous immersion (beyond 1m)

- IP69K: Protected against high-pressure, high-temperature jet sprays

For most outdoor applications, IP68-rated connectors provide excellent protection, while specialized industrial settings might require IP69K for wash-down environments.

Key Applications for Waterproof Connectors

Waterproof connectors are essential in numerous industries and applications:

- Automotive: Headlights, taillights, engine wiring, sensors

- Outdoor Lighting: Garden, street, and architectural lighting

- Marine: Boats, underwater equipment, docks

- Industrial: Machinery in harsh environments, factory automation

- Agriculture: Irrigation systems, monitoring equipment

- Renewable Energy: Solar installations, wind turbines

- Security Systems: Outdoor cameras, access controls