When I first started working with cable connectors 15 years ago, I was overwhelmed by the variety. Customers would ask me which connector they needed, and I had to learn them all quickly.

The global market features over 100 different types of cable connectors, but this article focuses on the 8 most important ones: waterproof connectors, USB, HDMI, RJ45, fiber optic, Type-C, solar connectors, and energy storage connectors, which together dominate most applications from data transfer to renewable energy systems.

Understanding these connector types changed my business completely. When I moved from sales to manufacturing, knowing each type helped me serve customers better. Today, I want to share what I learned to help you choose the right connector for your needs.

In the following sections, I will analyze different cable connector types from multiple perspectives to help you make informed decisions. We will explore how waterproof connectors provide essential protection in harsh environments, how USB connectors handle modern device connectivity requirements, why HDMI connectors dominate audio-visual systems, what critical role RJ45 connectors play in network infrastructure, how fiber optic connectors enable high-speed communications, why USB Type-C is becoming the universal standard, how solar connectors support renewable energy systems, what makes energy storage connectors critical for battery systems, and finally how you can choose the right connector supplier for your specific needs.

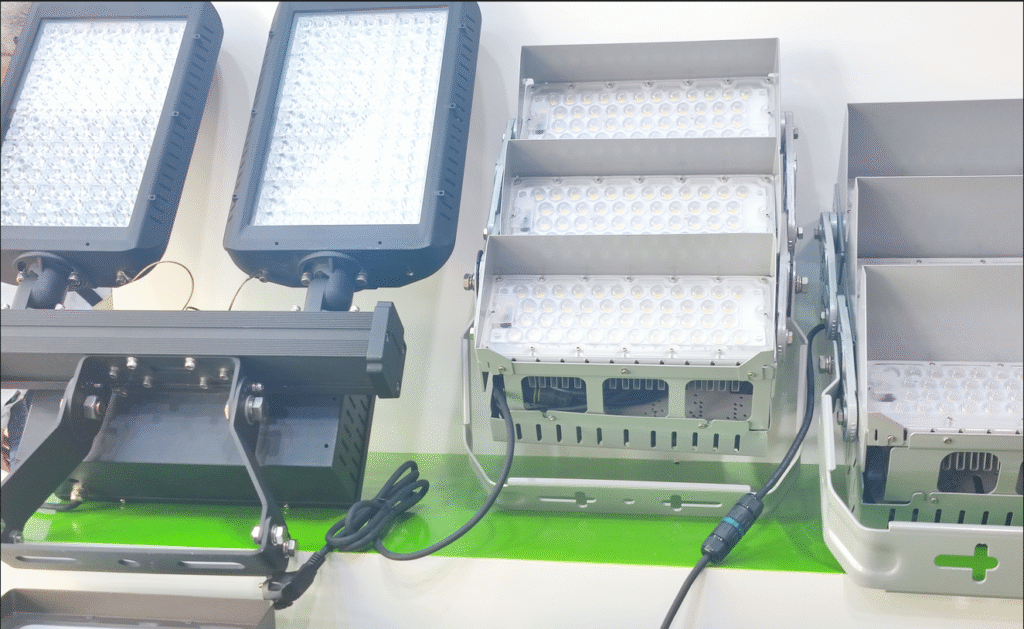

What Makes Waterproof Connectors Essential For Harsh Environments?

Waterproof connectors saved my reputation early in my career. A marine customer needed connectors for boat lighting systems, and regular connectors failed within months.

Waterproof connectors use rubber gaskets and O-rings to create IP65-IP68 rated seals, protecting electrical connections from water, dust, and corrosion in marine, outdoor, and industrial applications where moisture exposure is unavoidable.

I learned that IP ratings determine protection levels. IP65 handles water sprays and dust. IP67 survives temporary submersion up to 1 meter. IP68 works underwater for extended periods. The sealing technology uses compressed rubber materials that create barriers against moisture while maintaining electrical insulation.

| IP Rating | Protection Level | Water Resistance | Typical Applications |

|---|---|---|---|

| IP65 | Dust-tight + Water jets | Water sprays from any direction | Outdoor LED displays, street lighting |

| IP67 | Dust-tight + Immersion | 1 meter depth for 30 minutes | Marine equipment, pool lighting |

| IP68 | Dust-tight + Submersion | Extended underwater use | Underwater cameras, submarine cables |

These connectors appear in outdoor LED displays, marine equipment, industrial automation, and medical devices. They cost more than regular connectors but prevent expensive system failures. The investment pays off when your equipment keeps working despite harsh weather, saltwater exposure, or chemical environments.

In my factory, we see waterproof connectors used in everything from underwater cameras to offshore oil platforms. The key is matching the IP rating to your specific exposure risks. Choose IP65 for outdoor electronics, IP67 for temporary submersion, and IP68 for permanent underwater installations.

How Do USB Connectors Handle Modern Device Connectivity?

USB connectors confuse many people because there are multiple versions and types. When I started my factory, customers brought different USB cables, asking if they worked together.

USB connectors include USB-A (rectangular standard), USB-B (square for peripherals), Micro-USB (small devices), and Mini-USB (legacy equipment), with data speeds from 480 Mbps to 5 Gbps depending on the USB standard version.

USB-A connectors are the rectangular ones on computers and chargers. They come in black for USB 2.0 and blue for USB 3.0. USB-B connectors have a square shape and connect printers and external hard drives to computers. Micro-USB dominated older smartphones and still appears on power banks and game controllers.

| USB Standard | Data Speed | Power Output | Color Coding | Backward Compatibility |

|---|---|---|---|---|

| USB 2.0 | 480 Mbps | 2.5W (5V, 0.5A) | Black connector | Full compatibility |

| USB 3.0 | 5 Gbps | 4.5W (5V, 0.9A) | Blue connector | Compatible with USB 2.0 |

| USB 3.1 | 10 Gbps | 100W (20V, 5A) | Blue/teal connector | Compatible with previous versions |

| USB 3.2 | 20 Gbps | 100W (20V, 5A) | Blue/teal connector | Full backward compatibility |

Each USB type has different capabilities. USB 2.0 handles 480 Mbps data transfer. USB 3.0 reaches 5 Gbps. The newer versions also deliver more power for charging larger devices. Understanding these differences helps avoid compatibility issues and performance bottlenecks.

| USB Type | Shape | Data Speed | Power Delivery | Common Uses |

|---|---|---|---|---|

| USB-A | Rectangular | Up to 5 Gbps | Up to 2.5W | Computers, chargers |

| USB-B | Square | Up to 5 Gbps | Up to 4.5W | Printers, external drives |

| Micro-USB | Small oval | Up to 480 Mbps | Up to 2.5W | Smartphones, power banks |

| Mini-USB | Small rectangle | Up to 480 Mbps | Up to 2.5W | Cameras, MP3 players |

I see USB connectors in consumer electronics, computer peripherals, charging stations, and data transfer applications. They work well for indoor use but need protection in harsh environments. For outdoor or industrial applications, waterproof USB variants provide better reliability.

Why Are HDMI Connectors Dominating Audio-Visual Systems?

HDMI connectors revolutionized how we connect displays and audio equipment. Before HDMI, we needed separate cables for video and audio signals.

HDMI connectors transmit high-definition video and audio through a single cable, supporting resolutions up to 8K and advanced features like HDR, making them essential for home theaters, gaming systems, and professional displays.

Different HDMI versions offer varying capabilities. HDMI 1.4 supports 4K at 30fps. HDMI 2.0 handles 4K at 60fps. HDMI 2.1 reaches 8K resolution and 120fps for gaming. The connector design remains the same, but the internal capabilities improve with each version.

| HDMI Version | Max Resolution | Frame Rate | Bandwidth | Key Features |

|---|---|---|---|---|

| HDMI 1.4 | 4K (3840×2160) | 30fps | 10.2 Gbps | Basic 4K support |

| HDMI 2.0 | 4K (3840×2160) | 60fps | 18 Gbps | HDR support |

| HDMI 2.1 | 8K (7680×4320) | 120fps | 48 Gbps | Gaming features, VRR |

These connectors appear in televisions, gaming consoles, streaming devices, projectors, and computer monitors. They simplify installations by combining video and audio in one cable. The digital signal maintains quality over longer distances compared to older analog connections.

Professional installations often require HDMI over fiber optic cables for very long runs. In my experience, standard HDMI cables work up to 15 meters. Beyond that distance, you need active cables or fiber optic solutions to maintain signal integrity.

What Role Do RJ45 Connectors Play In Network Infrastructure?

RJ45 connectors form the backbone of modern network infrastructure. Every office, factory, and data center depends on these connectors for reliable internet and data connections.

RJ45 connectors terminate Ethernet cables to provide network connectivity, supporting speeds from 10 Mbps to 10 Gbps depending on cable category (Cat5e, Cat6, Cat6a, Cat7), and featuring 8-pin connections for data transmission.

The connector design includes 8 pins arranged in specific patterns. Each pin carries different signals for transmit and receive functions. The plastic clips ensure secure connections that resist accidental disconnection. Color coding helps technicians wire connections correctly.

Cable categories determine performance levels. Cat5e handles Gigabit speeds up to 100 meters. Cat6 supports 10 Gigabit over shorter distances. Cat6a and Cat7 maintain 10 Gigabit performance over full 100-meter runs. The RJ45 connector remains the same, but internal specifications change.

| Cable Category | Max Speed | Max Distance | Frequency | Typical Use |

|---|---|---|---|---|

| Cat5e | 1 Gbps | 100 meters | 100 MHz | Office networks |

| Cat6 | 10 Gbps | 55 meters | 250 MHz | Data centers |

| Cat6a | 10 Gbps | 100 meters | 500 MHz | High-performance networks |

| Cat7 | 10 Gbps | 100 meters | 600 MHz | Industrial applications |

In industrial environments, shielded RJ45 connectors reduce electromagnetic interference. They feature metal housings that protect against electrical noise from motors and other equipment. These connectors cost more but provide reliable connections in challenging electrical environments.

How Are Fiber Optic Connectors Enabling High-Speed Communications?

Fiber optic connectors handle the fastest data transmission available today. When customers need ultimate speed and distance, fiber optics becomes the only solution.

Fiber optic connectors like LC, SC, and ST types connect glass fiber cables for data transmission at light speed, supporting distances up to 40 kilometers and speeds exceeding 100 Gbps for telecommunications and data center applications.

LC connectors are small and popular in data centers due to high port density. SC connectors feature push-pull mechanisms for easy installation and removal. ST connectors use bayonet coupling and appear in older installations. Each type requires precise alignment to minimize signal loss.

| Connector Type | Design | Coupling Method | Port Density | Common Applications |

|---|---|---|---|---|

| LC | Small form factor | Push-pull latch | High | Data centers, modern networks |

| SC | Square shape | Push-pull | Medium | Telecommunications, campus networks |

| ST | Round with key | Bayonet twist | Low | Legacy installations, test equipment |

| FC | Threaded | Screw-on | Low | High-precision measurement systems |

The connectors must align glass fibers with extreme precision. Even tiny misalignments cause signal loss and poor performance. Proper cleaning and handling are critical because dust or scratches on fiber ends destroy signal quality. Special cleaning tools and techniques maintain optimal performance.

These connectors appear in telecommunications networks, data centers, long-distance internet backbones, and high-speed local networks. They cost more than copper alternatives but provide unmatched speed and distance capabilities. For applications requiring maximum performance, fiber optics are essential.

Why Is USB Type-C Becoming The Universal Standard?

USB Type-C represents the future of connector technology. Its reversible design and advanced capabilities make it superior to older connector types.

USB Type-C connectors feature reversible plug orientation, support USB4 speeds up to 80 Gbps, deliver up to 240W power, and handle video output, making them ideal for laptops, smartphones, and modern electronic devices.

The reversible design eliminates the frustration of trying to plug connectors upside down. The same port handles charging, data transfer, and video output. This versatility reduces the number of different ports needed on devices. Many laptops now use only USB Type-C ports.

Power delivery capabilities allow USB Type-C to charge everything from smartphones to laptops. The connector negotiates power requirements automatically and delivers the correct voltage and current. This smart charging prevents damage while maximizing charging speed.

| USB Type-C Feature | Specification | Benefit | Applications |

|---|---|---|---|

| Data Speed | Up to 80 Gbps (USB4) | Ultra-fast transfer | External storage, displays |

| Power Delivery | Up to 240W | Universal charging | Laptops, monitors, tablets |

| Video Output | 8K resolution | Single cable displays | Docking stations, monitors |

| Reversible Design | No wrong orientation | User convenience | All modern devices |

I see USB Type-C replacing older connector types across all device categories. Smartphones, tablets, laptops, and even some monitors now feature USB Type-C exclusively. The trend toward universal connectivity makes this connector increasingly important for manufacturers and consumers.

How Do Solar Connectors Support Renewable Energy Systems?

Solar connectors enable the growing renewable energy industry. These specialized connectors handle the unique requirements of photovoltaic systems and outdoor installations.

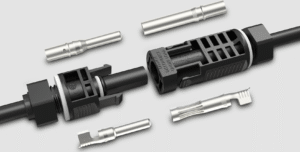

Solar connectors like MC4 types provide weatherproof connections for solar panels, featuring UV-resistant materials, locking mechanisms, and current ratings up to 30A for reliable power transmission in outdoor photovoltaic installations.

MC4 connectors dominate solar installations due to their reliability and ease of use. They feature positive locking mechanisms that prevent accidental disconnection. The weatherproof design handles years of outdoor exposure without degradation. Special tools ensure proper connections that maintain low resistance.

| Solar Connector Feature | Specification | Purpose | Benefits |

|---|---|---|---|

| Current Rating | Up to 30A | High power transmission | Efficient energy transfer |

| Voltage Rating | Up to 1500V DC | Solar panel compatibility | System scalability |

| Temperature Range | -40°C to +90°C | All-weather operation | Year-round reliability |

| UV Resistance | 25+ years | Long-term durability | Investment protection |

| IP Rating | IP67/IP68 | Weather protection | Maintenance-free operation |

These connectors must handle high voltages and currents while resisting UV radiation, temperature cycling, and weather exposure. The contact materials resist corrosion from moisture and atmospheric conditions. Proper installation prevents hot spots that could cause fires or system failures.

Solar installations require thousands of connector pairs in large systems. The connectors must maintain performance for 25+ years to match solar panel warranties. Quality connectors prevent expensive maintenance calls and system downtime. Choosing reliable solar connectors protects long-term investment returns.

What Makes Energy Storage Connectors Critical For Battery Systems?

Energy storage connectors handle the demanding requirements of battery systems in electric vehicles, grid storage, and backup power applications.

Energy storage connectors feature high current ratings (350A+), safety interlocks, temperature monitoring, and robust housings designed for lithium-ion battery packs, electric vehicle charging, and grid-scale energy storage systems.

These connectors handle much higher currents than typical data or power connectors. Electric vehicle charging requires 200-400 amp capabilities. Battery pack connections need reliable high-current paths that resist heating and voltage drop. Safety features prevent accidental contact with live circuits.

| Energy Storage Application | Current Rating | Voltage Range | Key Features | Safety Requirements |

|---|---|---|---|---|

| EV Charging Stations | 200-400A | 400-800V DC | Fast charging capability | Emergency disconnect |

| Battery Pack Internal | 300-500A | 400-1000V DC | High cycle life | Temperature monitoring |

| Grid Storage Systems | 1000A+ | 1500V DC | Parallel connections | Arc fault protection |

| Backup Power Systems | 100-200A | 48-400V DC | Reliable switching | Overcurrent protection |

Temperature monitoring capabilities detect overheating conditions that could indicate poor connections or system problems. Smart connectors communicate status information to battery management systems. This data helps prevent failures and extends battery life through proper monitoring.

The automotive and energy storage industries demand extreme reliability. Connector failures in these applications can cause expensive damage or safety hazards. Proper connector selection and installation are critical for system safety and performance. Quality connectors justify their higher cost through improved reliability.

How Can You Choose The Right Connector Supplier?

Finding the right connector supplier makes the difference between project success and failure. Over my 15 years in this industry, I have seen how supplier choice affects quality, delivery, and long-term support.

Choosing the right connector supplier requires evaluating their technical expertise, quality certifications, manufacturing capabilities, and industry experience to ensure reliable products and support for your specific application requirements.

So I organized a comprehensive Connector Supplier Evaluation Guide that can help you better assess and find suitable connector suppliers. This guide provides value in quality assurance, technical support, and cost optimization aspects.

The guide covers supplier certification requirements, quality testing procedures, and technical capability assessments. It helps you avoid common supplier selection mistakes that could cost thousands in failed products or delayed projects. Proper supplier evaluation saves time and money while ensuring reliable connector performance.

| Evaluation Criteria | What to Check | Red Flags | Benefits |

|---|---|---|---|

| Quality Certifications | ISO 9001, UL, CE marks | Missing certificates | Consistent product quality |

| Technical Support | Engineering assistance | Limited support hours | Custom solution development |

| Manufacturing Capability | Production capacity, equipment | Outdated facilities | Reliable delivery schedules |

| Industry Experience | Years in business, references | No similar projects | Application expertise |

| Cost Structure | Transparent pricing | Hidden fees | Budget predictability |

Quality assurance sections detail how to verify supplier certifications, inspect manufacturing processes, and validate product testing. Technical support evaluation helps identify suppliers who provide engineering assistance, custom solutions, and ongoing support. Cost optimization strategies balance price with quality and service levels.

This evaluation framework has helped my customers avoid supplier problems and build lasting partnerships with reliable manufacturers. The right supplier becomes a strategic partner who contributes to your project’s success beyond just providing products.

Conclusion

This comprehensive guide has analyzed the eight essential cable connector types from technical performance, application scenarios, and practical implementation perspectives. Understanding how waterproof connectors protect against harsh environments, how USB connectors enable modern device connectivity, why HDMI dominates audio-visual systems, the critical role of RJ45 in network infrastructure, how fiber optics enable high-speed communications, why Type-C is becoming universal, how solar connectors support renewable energy, what makes energy storage connectors critical for battery systems, and how to choose the right supplier – all these insights help you make better connector decisions for your projects.