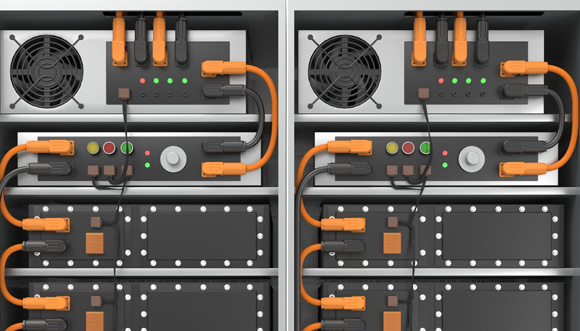

Energy storage systems fail when poor connections create safety hazards, power losses, and system downtime.

The top 10 energy storage connector manufacturers include TE Connectivity, Amphenol, Weidmüller, Phoenix Contact, Molex, HARTING, Beisit, Degson, AGX Connector, and Guchen Electronics, specializing in high-performance electrical connections for battery energy storage systems (BESS).

The energy storage industry is growing exponentially, but many projects fail due to connector issues. I have seen companies lose millions when cheap connectors cause fires or system failures. After 15 years helping clients choose the right connectors for energy storage applications, I know quality connections make the difference between project success and disaster. Let me share the manufacturers that lead this critical industry.

Complete Top 10 Energy Storage Connector Manufacturers Rankings

Based on a comprehensive analysis of energy storage connector specialization, technical capabilities, and market presence, here are the top 10 manufacturers serving the global energy storage connector market in 2025:

| Rank | Company | Founded | Specialty | Key Markets | IP Rating | Annual Revenue |

|---|---|---|---|---|---|---|

| 1 | TE Connectivity | 1941 | BESS solutions | Battery Storage Systems | IP67/68/69K | $16.3B |

| 2 | Amphenol Industrial | 1932 | High-power ESS connectors | Energy Storage, Industrial | IP67/68/69K | $12.6B |

| 3 | Weidmüller | 1850 | Battery pole connectors | ESS, Industrial Connectivity | IP65/67/68 | $980M |

| 4 | Phoenix Contact | 1923 | Energy storage systems | ESS, Industrial Automation | IP65/67/68 | $3.5B |

| 5 | Molex | 1938 | Energy storage connectivity | Electronics, ESS | IP65/67/68 | $6.2B |

| 6 | HARTING | 1945 | Industrial energy connectors | Manufacturing, ESS | IP67/68/69K | $890M |

| 7 | Beisit | 2005 | High-current ESS connectors | Energy Storage, Power Systems | IP67/68 | $180M |

| 8 | Degson Electronics | 1990 | ESS connector solutions | Energy Storage, Industrial | IP67/68 | $120M |

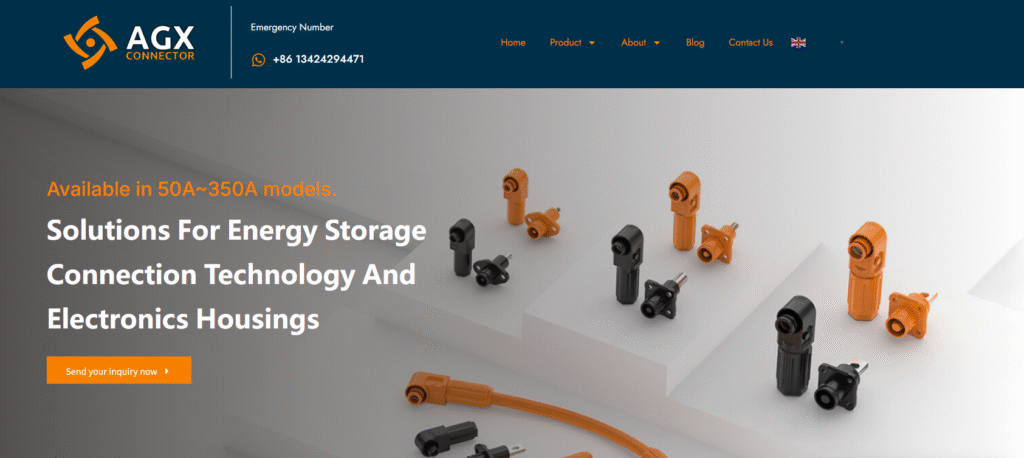

| 9 | AGX Connector | 2010 | Professional ESS connectors | Energy Storage, Outdoor | IP67/68/69K | $15M |

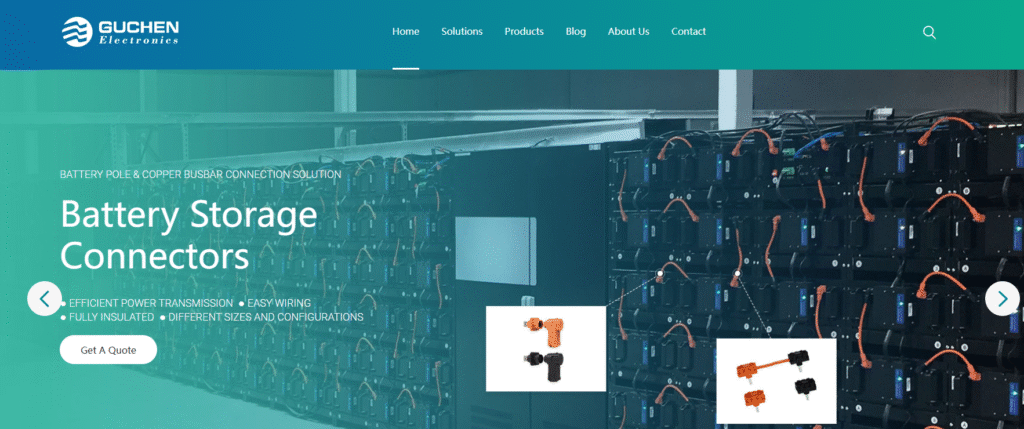

| 10 | Guchen Electronics | 2010 | BESS & EV connectors | Battery Storage, EV charging | IP67/68 | $25M |

What Makes Energy Storage Connectors Different from Regular Electrical Connectors?

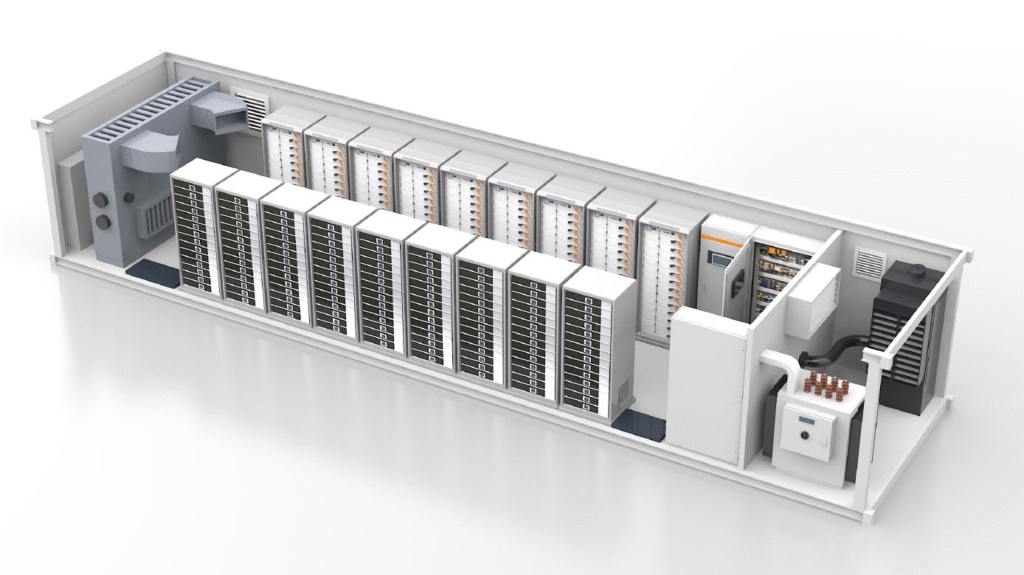

Energy storage systems require specialized connectors designed for extremely high-power applications that can withstand the stresses of standard electrical components.

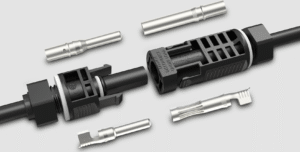

Energy storage connectors must handle high voltage (up to 1500V DC), massive current loads (50A-350A per connector), extreme temperature cycling (-40°C to +125°C), conductor cross-sections from 16mm² to 120mm², and provide fail-safe operation with touch-proof designs and IP67-IP69K environmental protection.

I have worked with many clients who learned this lesson the hard way. Regular connectors fail catastrophically in energy storage applications, frequently resulting in fires or explosions. The technical requirements for battery energy storage system (BESS) connectors are completely different from typical electrical work.

Energy storage connectors face extreme challenges in modern battery systems. The Weidmüller Battery Connector (WBC) exemplifies industry requirements – it enables connection of conductor cross-sections ranging from 16 mm² to 95 mm² on the connector side, with counterpart busbars handling massive current flows. These systems must support battery modules rated up to 350A continuous current.

Safety becomes critical when dealing with battery storage systems operating at 1500V DC. Poor connections cause thermal runaway, fires, explosions, or complete system failures. Energy storage connectors must provide:

- Touch-proof designs preventing accidental contact

- Polarity reversal protection with clear color coding (orange for positive, black for negative)

- Mechanical coding to prevent incorrect connections

- HVIL (High Voltage Interlock Loop) integration

The technical specifications for energy storage connectors far exceed regular electrical work. Modern energy storage connectors like the GCS1 series support:

- Rated currents from 50A to 350A

- Rated voltage up to 1500V DC

- Conductor cross-sections from 16mm² to 120mm²

- Insulation resistance of 5000MΩ

- Operating temperatures from -40℃ to +125℃

- 360° rotation capability for flexible cable routing

- Secondary locking mechanisms for safety

Environmental protection must reach IP67-IP69K ratings to protect against moisture, dust, high-pressure water jets, and chemical exposure. The materials include:

- Copper alloy contacts with silver-plated surfaces

- High-temperature PA 66 housings

- Specialized sealing systems maintain integrity under extreme conditions

| Feature | Regular Connectors | Energy Storage Connectors |

|---|---|---|

| Voltage Rating | Up to 600V AC | Up to 1500V DC |

| Current Capacity | 10-30A typical | 50A-350A per connector |

| Conductor Cross-Section | Up to 6mm² | 16mm² to 120mm² |

| Environmental Rating | IP54-IP65 | IP67-IP69K |

| Safety Features | Basic | Touch-proof, coding, arc protection, thermal management |

| Temperature Range | -20°C to +85°C | -40°C to +125°C |

| Installation | Tools required | Touch-safe, quick-connect, 360° rotation |

| Contact Material | Tin/nickel plated | Silver-plated copper alloy |

Which Companies Truly Specialize in Energy Storage Connector Manufacturing?

The energy storage connector market includes both specialized manufacturers focused exclusively on battery systems and established connector companies with dedicated energy storage divisions.

Leading energy storage connector specialists include TE Connectivity’s BESS Division, Amphenol Industrial Operations, Weidmüller, Phoenix Contact, Molex Energy Solutions, HARTING, Beisit, Degson Electronics, AGX Connector (50A-350A specialist), and Guchen Electronics, each bringing unique expertise to the battery energy storage market.

The industry divides into clear categories based on specialization level and market focus. Major global manufacturers like TE Connectivity and Amphenol leverage decades of experience in demanding applications to serve the energy storage market. Regional specialists like AGX Connector and Guchen Electronics focus exclusively on battery connection technology with innovative solutions.

Global Leaders in Energy Storage Connectors:

TE Connectivity leads with comprehensive BESS solutions, leveraging 80+ years of connector expertise. Their dedicated Battery Energy Storage System division provides complete connectivity solutions, including relays, connectors, switches, and electrical products specifically designed for energy infrastructure needs.

Amphenol Industrial Operations has developed comprehensive energy storage solutions, leveraging its aerospace and military connector expertise for battery management systems and high-power applications. Their RADSOK technology provides superior current density and reliability.

Weidmüller offers the innovative Weidmüller Battery Connector (WBC) system, enabling connection of conductor cross-sections from 16mm² to 95mm². Their 175+ years of industrial connectivity experience translate directly to energy storage requirements.

Phoenix Contact provides comprehensive energy storage solutions, including battery pole connectors, busbar connections, and complete system integration for applications up to 1,500V. Their German engineering focuses on industrial and energy applications.

Molex creates connections for life across industries, including energy storage. The company focuses on next-generation technology for battery energy storage systems with compact, high-density solutions.

Specialized Energy Storage Manufacturers:

HARTING applies its industrial automation expertise to energy storage applications, offering solutions for transportation technology and renewable energy systems with German quality standards.

Beisit specializes in high-current energy storage connectors with innovative designs for battery management systems, focusing on reliability and ease of installation for large-scale ESS projects.

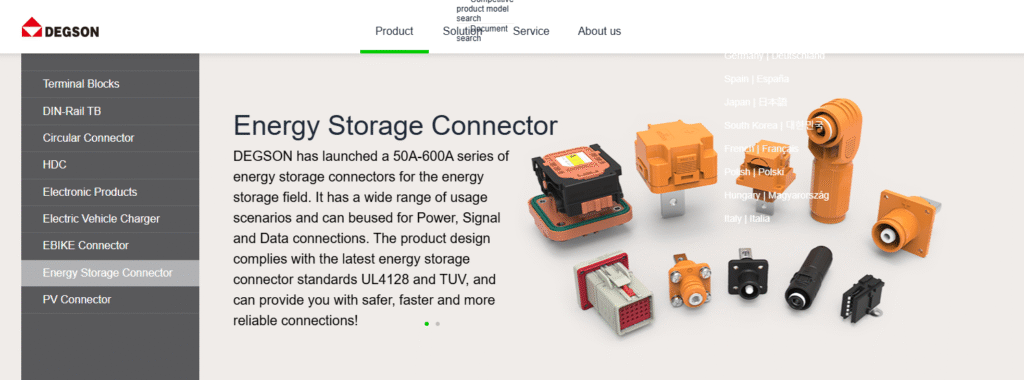

Degson Electronics has established itself as a major player in energy storage connectivity since 1990, offering a comprehensive 50A-600A series of energy storage connectors compliant with UL4128 and TUV standards.

AGX Connector specializes in professional energy storage connectors from 50A to 350A, offering innovative 90-degree oriented designs with 360° rotation capability. Their focus on safety includes tool-free installation and UL4128 certification.

Guchen Electronics specializes exclusively in high-voltage connectors for electric vehicles and battery energy storage systems (BESS), offering GCS1 series connectors with current ratings up to 350A.

Why Specialization Matters in Energy Storage:

Energy storage connectors require unique expertise that differs significantly from general electrical connectors. Specialized manufacturers understand critical requirements, including:

- Thermal runaway prevention

- HVIL (High Voltage Interlock Loop) integration

- 1500V DC voltage handling

- IP69K environmental protection for outdoor installations

The choice between global leaders and specialized manufacturers depends on specific application requirements, support needs, and project scale. Global manufacturers provide extensive support networks and proven reliability, while specialists often lead in innovation and customization.

How Do These Manufacturers Ensure Connector Reliability in Critical Energy Storage Applications?

Leading manufacturers use rigorous testing protocols, premium materials, and advanced safety features to guarantee connector performance in life-critical energy storage systems operating at 1500V DC.

Top energy storage connector manufacturers ensure reliability through extensive environmental testing (thermal cycling -40°C to +125°C, vibration, salt spray), premium materials like silver-plated copper alloy contacts, redundant safety features including HVIL (High Voltage Interlock Loop), international certifications (UL4128, IEC62619, NFPA855), and proven track records in demanding aerospace and automotive applications.

Quality control for energy storage connectors begins with premium material selection. The Weidmüller Battery Connector (WBC) uses copper alloy contacts with silver-plated surfaces and PA 66 high-temperature housing materials. Silver plating provides outstanding longevity and low resistance when applied in high-power, elevated temperature environments.

Testing processes for energy storage connectors are comprehensive and brutal. Manufacturers conduct:

- Thermal cycling from -40°C to +125°C for 800+ cycles

- Vibration testing that simulates years of operation

- Salt spray corrosion tests for 2000+ hours

- Humidity freeze testing for 60+ cycles

- Electrical performance verification under maximum load conditions

Safety certifications provide independent verification of critical performance. Major standards include:

- UL4128 for energy storage connector safety

- IEC62619 for lithium battery safety

- NFPA855 for energy storage system installations

- UL1977 for high-voltage DC connectors

Advanced safety features separate energy storage connectors from regular electrical products:

- Touch-proof designs prevent accidental contact even when unplugged

- Mechanical coding with specific keying prevents incorrect mating

- Polarity reversal protection with clear color coding

- Secondary locking mechanisms ensure connections cannot vibrate loose

- HVIL circuits monitor connector integrity in real-time

Manufacturing quality systems ensure consistency at every step. Products undergo comprehensive mechanical testing and electronic performance verification. Fully automated inspections during production catch defects before they reach customers. Many manufacturers offer free sample services for testing before large orders.

Key Reliability Testing Standards for Energy Storage Connectors

Environmental Testing:

- Thermal cycling: -40°C to +125°C, 800+ cycles

- Vibration resistance: 10-2000 Hz, 20g acceleration

- Salt spray corrosion: 2000+ hours exposure

- Humidity freeze: 60+ cycles

- UV resistance for outdoor installations

Electrical Performance:

- Insulation resistance: 5000MΩ minimum

- Contact resistance: <0.5mΩ typical

- Voltage withstand: 3000V AC test voltage

- Current carrying: 110% rated current continuous

- Arc interruption capability testing

Safety Certifications:

- UL4128: Energy storage connector safety standards

- IEC62619: Lithium battery safety requirements

- NFPA855: Energy storage system installations

- UL1977: High-voltage DC connector safety

- IEC62852: Photovoltaic connector standards

What Emerging Technologies Are Transforming Energy Storage Connectors?

Advanced technologies are revolutionizing energy storage connectors to meet the demands of next-generation battery systems operating at 1500V DC and smart grid applications.

Emerging energy storage connector technologies include smart connectors with integrated temperature and current monitoring, ultra-high power density designs handling 350A+ in compact packages, advanced thermal management with phase-change materials, HVIL (High Voltage Interlock Loop) safety systems, liquid metal shielding for EMI protection, and modular blind-mate connections for rapid battery module replacement.

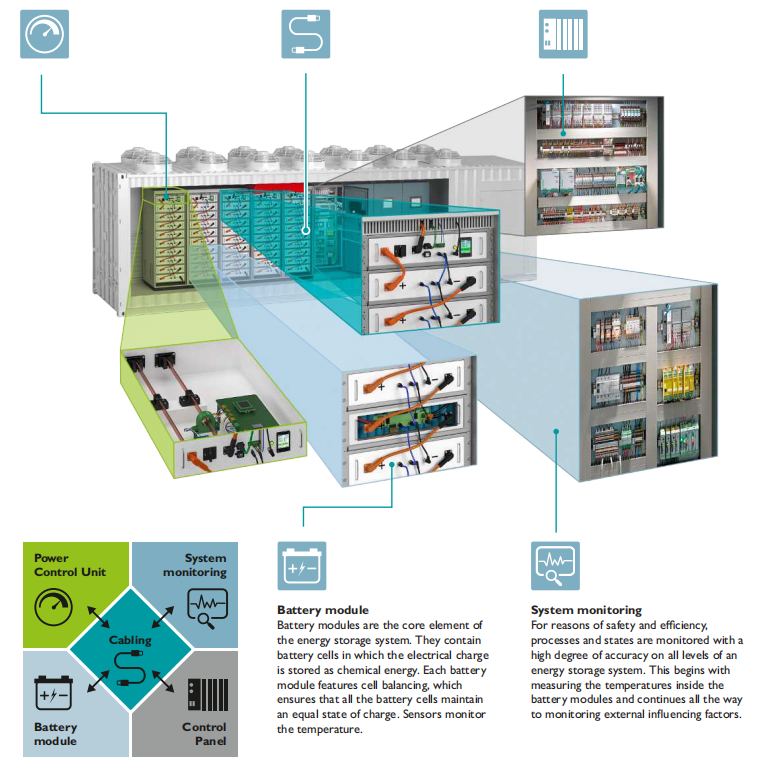

Smart connectivity is becoming the industry standard for energy storage connectors. Modern connectors integrate sensors for real-time temperature monitoring, current measurement, and connection status verification. These systems can predict thermal runaway before it occurs and automatically disconnect power to prevent catastrophic failures.

Power density improvements allow smaller connectors to handle massive currents. The latest connectors achieve 350A ratings in compact designs, using conductor cross-sections up to 120mm². Advanced contact geometries and silver-plated surfaces minimize resistance heating while maximizing current density.

Thermal management advances in energy storage connectors include:

- Phase-change materials that absorb heat during peak loads

- Integrated heat pipes that move thermal energy away from connection points

- Advanced contact designs with multiple contact points

- 90-degree oriented designs for better heat dissipation

High Voltage Interlock Loop (HVIL) technology monitors connector integrity in real-time. If any connector becomes loose, damaged, or experiences thermal issues, the HVIL circuit immediately signals the battery management system to shut down power flow.

Advanced materials development for energy storage connectors includes:

- Self-healing polymers for automatic damage repair

- Nano-enhanced contact plating for superior conductivity

- High-temperature thermoplastics maintain properties at 150°C+

- Specialized sealing compounds providing IP69K protection

The industry is moving toward complete system integration, where connectors become intelligent components of the energy storage system. Current developments focus on:

- Sensors for real-time monitoring

- Current ratings exceeding 350A in compact packages

- Advanced safety systems like HVIL monitoring

- Superior environmental protection for 25+ year outdoor installations

How Should Engineers Select the Right Energy Storage Connector Manufacturer?

Selecting the right energy storage connector manufacturer requires evaluating technical capabilities, industry experience, quality certifications, and long-term support rather than focusing solely on initial purchase price.

Engineers should evaluate energy storage connector manufacturers based on relevant certifications (UL4128, IEC62619), proven track record in BESS applications, technical support quality, global availability, customization capabilities, and total cost of ownership, including reliability, maintenance, and lifecycle factors.

Technical capability assessment starts with understanding your specific requirements for energy storage connectors. Different applications need different solutions – residential storage differs significantly from utility-scale installations in voltage, current, environmental requirements, and safety standards.

Consider these key evaluation criteria:

Technical Requirements:

- Voltage and current ratings matching your system (50A-350A, up to 1500V DC)

- Environmental specifications (IP67-IP69K)

- Safety certifications needed (UL4128, IEC standards)

- Installation requirements (90-degree oriented, straight, panel mount)

Manufacturer Capabilities:

- Design engineering support

- Customization options

- Testing facilities

- Quality certifications

- Sample availability

Business Factors:

- Global or local availability

- Technical support quality

- Delivery reliability

- Total cost of ownership

From my experience helping customers select energy storage connectors, the lowest price option often creates the highest total cost through failures, downtime, and replacement costs. Quality manufacturers provide better documentation, technical support, and product consistency.

Complete Top 10 Manufacturer Profiles

1. TE Connectivity

| Company Name | TE Connectivity |

|---|---|

| Founded | 1941 |

| Website | https://www.te.com |

| Headquarters | Schaffhausen, Switzerland |

| Main Business | Connectivity and sensor solutions |

| Key Products | DEUTSCH automotive connectors, AMP industrial connectors, BESS solutions, high-temperature connectors |

| Specialty | Battery Energy Storage System connectivity |

| Value Advantage | Global leader with proven reliability, extensive R&D investment, comprehensive testing capabilities |

Overview: TE Connectivity operates as one of the world’s largest connector manufacturers with over 80 years of experience. Their dedicated BESS Solutions division provides complete battery energy storage system solutions, including relays, connectors, switches, and electrical products specifically designed for energy infrastructure needs. They maintain manufacturing facilities globally and invest heavily in advanced automation and quality control systems for energy storage applications.

2. Amphenol Corporation

| Company Name | Amphenol Corporation |

|---|---|

| Founded | 1932 |

| Website | https://www.amphenol.com |

| Headquarters | Wallingford, Connecticut, USA |

| Main Business | Aerospace heritage, superior current density technology, and comprehensive testing capabilities |

| Key Products | Industrial power connectors, RADSOK contacts, energy storage connectors, harsh environment solutions |

| Specialty | Military-grade reliability for energy storage applications |

| Value Advantage | Aerospace heritage, superior current density technology, comprehensive testing capabilities |

Overview: Amphenol Corporation operates as a global leader in connector manufacturing with over 90 years of experience. Founded by Arthur J. Schmitt in Chicago, the company expanded significantly during World War II as the primary manufacturer of connectors for military hardware. Today, Amphenol Industrial Operations has developed comprehensive energy storage solutions, leveraging its aerospace and military connector expertise for battery management systems and high-power applications.

3. Weidmüller

| Company Name | Weidmüller |

|---|---|

| Founded | 1850 |

| Website | https://www.weidmuller.com |

| Headquarters | Detmold, Germany |

| Main Business | Industrial connectivity and automation |

| Key Products | Weidmüller Battery Connector (WBC), energy storage systems up to 1500V, conductor cross-sections 16mm²-95mm² |

| Specialty | Industrial connectivity, energy storage management, and battery connection technology |

| Value Advantage | 175+ years experience, comprehensive energy storage portfolio, German engineering excellence |

Overview: Weidmüller offers comprehensive solutions for energy storage, including the innovative Weidmüller Battery Connector (WBC) that enables connection of conductor cross-sections ranging from 16 mm² to 95 mm². The WBC system features clear pole markings (orange for positive, black for negative), available in versions up to 120A, 200A, and 350A. Their energy storage solutions include battery management, emergency power supply, reliable connectivity, and Ethernet communication.

4. Phoenix Contact

| Company Name | Phoenix Contact |

|---|---|

| Founded | 1923 |

| Website | https://www.phoenixcontact.com |

| Headquarters | Blomberg, Germany |

| Main Business | Industrial automation and connectivity |

| Key Products | Battery pole connectors, busbar connectors, energy storage systems up to 1500V |

| Specialty | Industrial automation and energy storage connectivity |

| Value Advantage | German engineering excellence, comprehensive energy storage portfolio, extensive customization |

Overview: Phoenix Contact provides innovative connection technology that enables safe wiring of energy storage systems. Their products support applications up to 1,500 V with connectors for front and rear connection to energy storage devices. The company offers comprehensive solutions from residential storage to utility-scale installations, with a focus on industrial automation integration.

5. Molex

| Company Name | Molex |

|---|---|

| Founded | 1938 |

| Website | https://www.molex.com |

| Headquarters | Lisle, Illinois, USA |

| Main Business | Electronic connectivity solutions |

| Key Products | Board-to-board connectors, wire-to-wire solutions, high-speed connectors, ESS connectivity |

| Specialty | Miniaturization and high-density connectivity |

| Value Advantage | Innovation in compact designs, a comprehensive product portfolio, and global manufacturing |

Overview: Molex creates connections for life across industries, including energy storage. The company focuses on next-generation technology for data centers, vehicles, industrial environments, and battery energy storage systems. Their connectors help applications run reliably in demanding environments with a focus on miniaturization and high-density solutions.

6. HARTING

| Company Name | HARTING |

|---|---|

| Founded | 1945 |

| Website | https://www.harting.com |

| Headquarters | Espelkamp, Germany |

| Main Business | Industrial connectivity and network components |

| Key Products | Heavy-duty connectors, industrial Ethernet, energy storage solutions |

| Specialty | Industrial connectivity and harsh environment applications |

| Value Advantage | German quality standards, extensive product range, strong industrial heritage |

Overview: HARTING designs and manufactures connectors, device connectivity, and network components primarily for industrial applications. The company provides solutions for automation technology, energy, transportation, and renewable energy markets. Their Energy Solutions division applies industrial automation expertise to energy storage applications with a focus on reliability and performance.

7. Beisit

| Company Name | Beisit Electric Co., Ltd. |

|---|---|

| Founded | 2005 |

| Website | https://www.beisit.com |

| Headquarters | Zhejiang, China |

| Main Business | High-current connector solutions |

| Key Products | Innovative designs, cost-effective solutions, and rapid customization |

| Specialty | High-current ESS connectors and power systems |

| Value Advantage | Innovative designs, cost-effective solutions, rapid customization |

Overview: Beisit specializes in high-current energy storage connectors with innovative designs for battery management systems. The company focuses on reliability and ease of installation for large-scale ESS projects, offering comprehensive solutions for power distribution in energy storage applications. Their products serve utility-scale battery storage systems worldwide.

8. Degson Electronics

| Company Name | Degson Electronics Co., Ltd. |

|---|---|

| Founded | 1990 |

| Website | https://www.degson.com |

| Headquarters | Ningbo, China |

| Main Business | Industrial connection solutions |

| Key Products | 35+ years of experience, UL and VDE accredited labs, ISO certifications |

| Specialty | Energy storage connector solutions compliant with UL4128 and TUV standards |

| Value Advantage | 35+ years experience, UL and VDE accredited labs, ISO certifications |

Overview: Founded in 1990, Degson is a world-famous industrial connection solution provider with professional laboratories accredited by both UL and VDE. The company has launched a comprehensive 50A-600A series of energy storage connectors for the energy storage field with wide usage scenarios for Power, Signal, and Data connections. Their product design complies with the latest energy storage connector standards UL4128 and TUV.

9. AGX Connector

| Company Name | Shenzhen AGX Technology Co., Ltd. |

|---|---|

| Founded | 2010 |

| Website | https://agxconnector.com |

| Headquarters | Shenzhen, China |

| Main Business | Energy storage connectors and waterproof junction boxes |

| Key Products | 90-degree oriented energy storage connectors (50A-350A), IP68 waterproof connectors, UL4128 certified BESS connectors |

| Specialty | Energy storage connectivity with 360° rotation and multiple angle mating |

| Value Advantage | Safety-focused design, tool-free installation, color-coded housings, IP67/68/69K protection |

Overview: AGX Connector specializes in professional energy storage connectors ranging from 50A to 350A for battery energy storage systems (BESS). Founded by industry veteran Cindy Lee with 15 years of experience, the company offers comprehensive solutions, including 90-degree oriented connectors with 360° rotation capability. Their products feature UL4128 1500VDC certification, multiple connection types, and operate from -40°C to +105°C with superior IP67/68/69K environmental protection.

10. Guchen Electronics

| Company Name | Guchen Electronics Co., Ltd. |

|---|---|

| Founded | 2010 |

| Website | https://www.guchen-connector.com |

| Headquarters | Shenzhen, China |

| Main Business | EV and energy storage connectors |

| Key Products | GCS1 series ESS connectors (6mm, 8mm, 12mm), battery pole connectors, copper busbar connectors |

| Specialty | BESS and EV high-voltage connector systems |

| Value Advantage | Specialized ESS focus, 360° rotation capability, secondary locking mechanisms |

Overview: Guchen Electronics specializes exclusively in electric vehicle high-voltage connectors and Battery Energy Storage System (BESS) connectors. Their GCS1 series includes 6mm (100A-120A), 8mm (120A-200A), and 12mm (250A-350A) connectors for voltages up to 1500V DC. Features include 360° rotation when plugged in, secondary locking functions, and mechanical coding for safety.

Conclusion: Choosing the Right Energy Storage Connector Manufacturer

The top 10 energy storage connector manufacturers combine decades of experience with cutting-edge technology to enable the global transition to renewable energy storage systems. When selecting a manufacturer for your battery energy storage system (BESS) project, consider these critical factors:

Technical Excellence: Leading manufacturers offer connectors rated for 1500V DC and 50A-350A current handling with IP69K protection.

Global vs. Specialized: Global leaders like TE Connectivity and Amphenol provide extensive support networks, while specialists like AGX Connector and Guchen Electronics offer innovative solutions.

Safety First: Look for manufacturers offering HVIL integration, touch-proof designs, and certifications including UL4128, IEC62619, and NFPA855.

Total Cost of Ownership: Quality connectors from reputable manufacturers ensure system safety, reliability, and optimal performance throughout the 20-25 year lifespan of modern energy storage installations.

Remember, the cost of connector failure in energy storage systems far exceeds any savings from choosing cheaper alternatives.

Why This Guide Matters for Your Energy Storage Project

This comprehensive guide to the top 10 energy storage connector manufacturers provides invaluable insights that can save your project from costly failures and ensure long-term success. Here’s how this information helps you:

Risk Mitigation: Understanding the differences between regular and energy storage connectors prevents catastrophic failures. I’ve seen projects lose millions due to wrong connector choices – this guide helps you avoid those expensive mistakes.

Informed Decision Making: With detailed profiles of each manufacturer’s strengths, specializations, and product ranges, you can match your specific project requirements with the right supplier, whether you need 50A residential connectors or 350A utility-scale solutions.

Technical Confidence: The clear explanation of critical specifications (voltage ratings, current capacity, IP protection, safety features) empowers you to communicate effectively with suppliers and ensure you’re getting exactly what your BESS project needs.

Cost Optimization: By understanding the total cost of ownership and the importance of quality, you can make budget decisions that save money over the 20-25 year lifespan of your energy storage system, rather than choosing cheap connectors that fail prematurely.

Future-Proofing: Knowledge of emerging technologies like smart connectors, HVIL integration, and advanced thermal management helps you select manufacturers who will support your system’s evolution and expansion.

Whether you’re an engineer designing your first residential energy storage system or a project manager overseeing utility-scale installations, this guide provides the foundation for making connector decisions that ensure safety, reliability, and optimal performance. The right connector choice today determines whether your energy storage system operates flawlessly for decades or becomes a costly liability.

Take time to evaluate these manufacturers against your specific needs. Request samples, verify certifications, and consider long-term support. Your energy storage system’s success depends on these critical connection points – make them count.

Frequently Asked Questions About Energy Storage Connectors

What is an energy storage connector?

An energy storage connector is a specialized electrical connection device designed to handle high voltage (up to 1500V DC) and high current (50A-350A) in battery energy storage systems (BESS), featuring advanced safety mechanisms, environmental protection (IP67-IP69K), and specialized designs like 90-degree orientation and 360° rotation capability.

How do I choose the right energy storage connector?

Select energy storage connectors based on voltage rating (typically 1000V-1500V DC), current capacity (50A-350A), environmental protection (IP67-IP69K), safety certifications (UL4128), installation type (90-degree oriented, straight, panel mount), and manufacturer reputation in BESS applications.

What makes AGX Connector different from other manufacturers?

AGX Connector specializes in professional energy storage connectors from 50A to 350A with unique 90-degree oriented designs, 360° rotation capability, tool-free installation, clear color-coded housings for safety (orange positive/black negative), UL4128 certification for 1500VDC, and IP67/68/69K waterproof protection.

Why are energy storage connectors so expensive?

Energy storage connectors require premium materials (silver-plated contacts), extensive safety testing, specialized certifications, and advanced features like HVIL integration and thermal management, justifying their higher cost compared to regular connectors.

Can I use regular electrical connectors for battery storage?

No, regular electrical connectors cannot handle the high voltage (1500V DC), massive currents (350A), and extreme conditions of energy storage systems. Using standard connectors risks fire, explosion, or system failure.

What certifications should energy storage connectors have?

Essential certifications include UL4128 (energy storage safety), IEC62619 (lithium battery safety), NFPA855 (installations), UL1977 (high-voltage DC), and IP67-IP69K environmental ratings.

How long do energy storage connectors last?

Quality energy storage connectors from reputable manufacturers typically last 20-25 years when properly installed and maintained, matching the lifespan of modern battery energy storage systems.

What is HVIL in energy storage connectors?

High Voltage Interlock Loop (HVIL) is a safety circuit that monitors connector integrity in real-time, immediately shutting down power if a connection becomes loose or damaged, preventing arc faults and thermal runaway.

Which countries manufacture the best energy storage connectors?

Germany (Weidmüller, Phoenix Contact, HARTING), USA (TE Connectivity, Amphenol, Molex), and specialized Chinese manufacturers (AGX Connector, Guchen, Degson, Beisit) lead in energy storage connector technology.

How do smart energy storage connectors work?

Smart connectors integrate temperature sensors, current monitoring, and wireless communication to provide real-time data to battery management systems, enabling predictive maintenance and preventing failures before they occur.