Choosing the wrong waterproof connector supplier can cost your business thousands in delays, quality issues, and lost customers.

The right waterproof connector supplier should offer proven quality certifications, competitive pricing, reliable delivery schedules, and strong technical support. Look for suppliers with ISO certifications, at least 5 years of industry experience, and positive customer reviews.

After 15 years in the waterproof connector industry, I’ve seen too many businesses struggle because they picked suppliers based on price alone. So I put together a complete supplier evaluation framework that helps you find reliable partners who deliver on their promises.

This guide will help you better evaluate and find the right connector supplier through proven criteria in quality verification, cost analysis, technical support assessment, and delivery performance evaluation. You’ll save time by avoiding unreliable suppliers and protect your business from costly mistakes that damage customer relationships.

In the following sections, I’ll walk you through essential supplier evaluation criteria covering quality standards verification to ensure consistent product performance, production capacity assessment to guarantee reliable supply, pricing, and payment term analysis to protect your profit margins, technical support evaluation to minimize project risks, and delivery logistics factors to maintain customer satisfaction. Each section provides practical tools and real-world insights that turn supplier selection from guesswork into a systematic process.

What Quality Standards Should Your Supplier Meet?

Poor quality connectors can destroy your reputation and cost you major contracts.

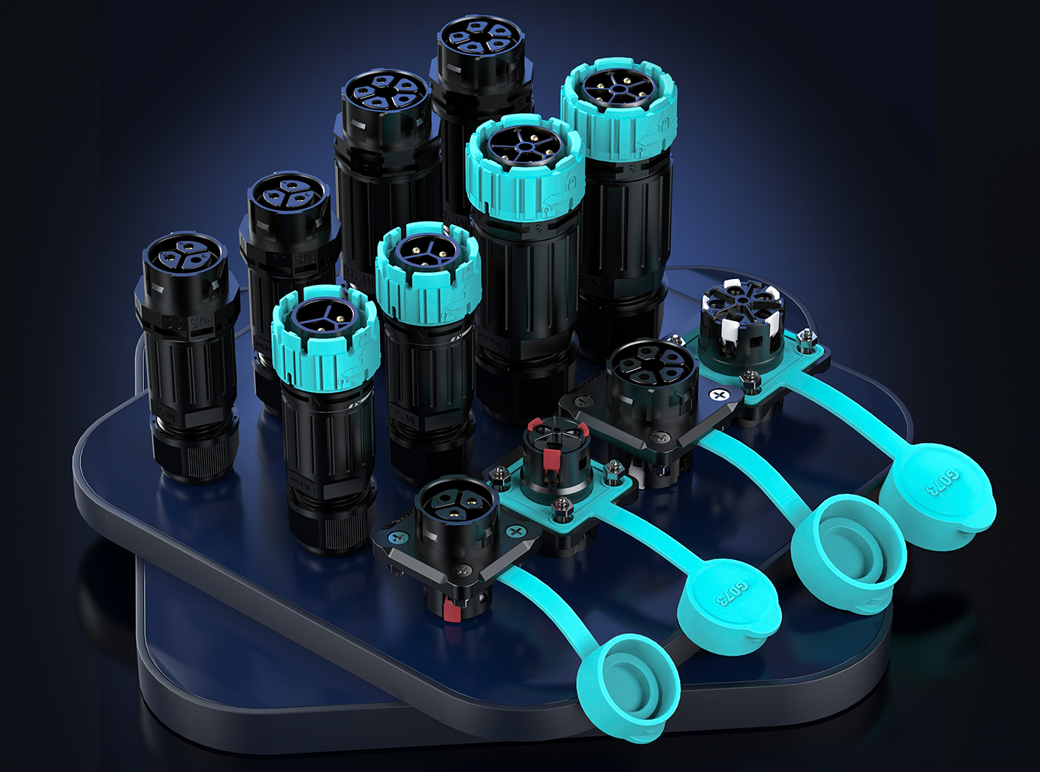

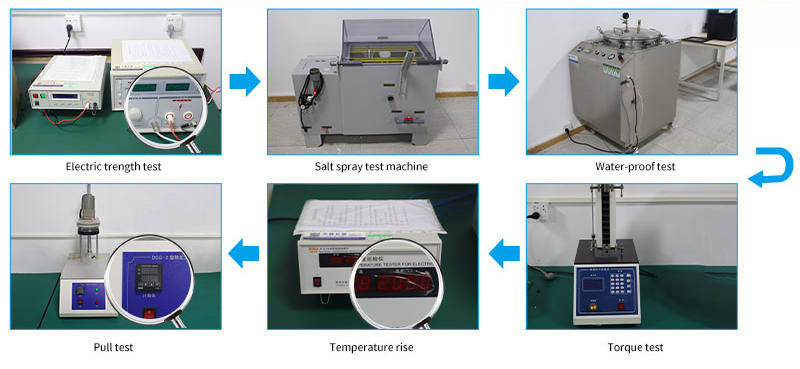

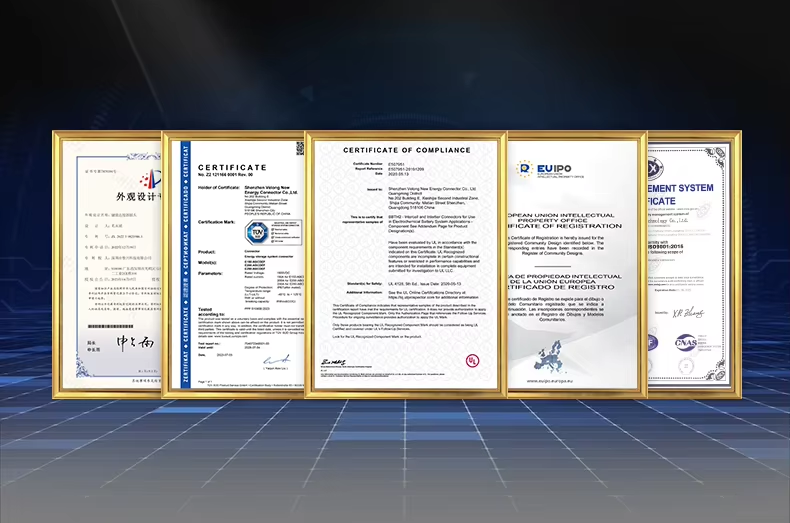

Your waterproof connector supplier must have ISO 9001 certification, IP67/IP68 rating compliance, and RoHS certification. These standards ensure consistent quality, proper waterproof performance, and environmental safety compliance.

Quality standards separate professional suppliers from unreliable ones. I always check three main areas when evaluating a supplier’s quality credentials.

First, look for ISO 9001 certification. This shows the supplier has proper quality management systems. Companies without this certification often have inconsistent products. I once worked with a distributor in Spain who lost a major automotive contract because their supplier couldn’t maintain consistent quality standards.

Second, verify IP rating compliance. Waterproof connectors must meet specific IP67 or IP68 standards. Ask for official test reports, not just certificates. Real test reports show actual performance data. Fake suppliers often provide certificates without proper testing.

Third, check for material certifications like RoHS and REACH compliance. These ensure your products meet environmental regulations in different markets. European customers especially require these certifications. Missing certifications can block your entire shipment at customs.

| Quality Standard | Purpose | Why It Matters |

|---|---|---|

| ISO 9001 | Quality management | Consistent production processes |

| IP67/IP68 | Waterproof rating | Reliable protection performance |

| RoHS | Material safety | Environmental compliance |

| UL Listed | Safety standards | Market acceptance |

How Can You Verify a Supplier’s Production Capacity?

Suppliers who promise big but can’t deliver will sink your business relationships.

Check the supplier’s factory size, equipment list, monthly output capacity, and existing customer base. Request factory photos, equipment specifications, and references from current customers to verify their actual production capabilities.

Production capacity determines whether your supplier can handle your orders consistently. Many suppliers overstate their capabilities to win business, and then fail to deliver.

Start by asking for factory specifications. Real manufacturers provide detailed information about their facilities. Ask for the factory floor area, number of production lines, and types of molding equipment. Legitimate suppliers share this information openly. Suppliers who avoid these questions often lack proper facilities.

Next, verify their monthly production capacity. Compare this with their existing customer commitments. A factory producing 100,000 units monthly with 95% capacity already committed cannot reliably handle your 20,000-unit order. Smart suppliers maintain 15-20% spare capacity for urgent orders and growth.

Request customer references from similar industries. Contact these references directly. Ask about delivery performance, quality consistency, and problem resolution. Past performance predicts future behavior. Suppliers with happy long-term customers usually provide reliable service.

Also, check their supply chain stability. Ask about their raw material suppliers and inventory levels. Suppliers with diverse material sources and adequate inventory avoid production delays. Single-source suppliers face higher risks during material shortages.

What Should You Know About Pricing and Payment Terms?

Hidden costs and unfavorable payment terms can destroy your profit margins.

Compare total landed costs including shipping, customs, and handling fees. Negotiate 10-30 days payment terms with new suppliers. Avoid suppliers demanding full payment upfront or offering prices significantly below market rates.

Pricing evaluation requires looking beyond the unit price. Many businesses make expensive mistakes by focusing only on the quoted price per piece.

Calculate total landed costs first. Include shipping, insurance, customs duties, and handling fees. A supplier offering $2.00 per unit might cost more than one charging $2.50 if shipping and handling add $0.75 versus $0.20. I help customers create spreadsheets comparing total costs from different suppliers.

Be suspicious of prices far below market rates. Extremely low prices often indicate quality compromises or hidden costs. Legitimate waterproof connectors require quality materials and proper manufacturing processes. Suppliers cutting prices by 40-50% below competitors usually cut quality too.

Negotiate reasonable payment terms. Established suppliers typically accept 30-day payment terms for regular customers. New suppliers might require deposits, but avoid full prepayment. Good compromise terms include a 30% deposit and a 70% balance before shipping. This protects both parties fairly.

Watch for hidden fees. Some suppliers add charges for packaging, documentation, or quality testing. Request detailed quotes showing all costs. Professional suppliers provide comprehensive quotes upfront. Suppliers adding surprise charges later often have poor business practices.

How Important Is Technical Support and Communication?

Poor communication leads to wrong products, missed deadlines, and frustrated customers.

Your supplier should provide English-speaking technical support, detailed product documentation, application guidance, and responsive customer service. Test their communication quality during initial discussions before placing orders.

Technical support quality directly impacts your success with waterproof connector projects. Suppliers with poor support create endless problems for your business.

Evaluate communication skills during initial contact. Professional suppliers respond to inquiries within 24 hours with detailed, helpful information. They ask relevant questions about your application requirements. Poor suppliers provide generic responses or ignore technical questions entirely.

Test their technical knowledge. Ask specific questions about IP ratings, material properties, or application requirements. Knowledgeable suppliers provide detailed explanations and suggest appropriate solutions. Suppliers who can’t answer basic technical questions lack proper expertise.

Check their documentation quality. Professional suppliers provide detailed datasheets, installation guides, and application notes. Clear documentation reduces installation problems and customer support issues. Poor documentation indicates the supplier doesn’t understand professional requirements.

Confirm their availability for ongoing support. Ask about their support hours, response times, and available communication channels. Reliable suppliers offer multiple contact methods and reasonable response times. Suppliers who disappear after taking your order create major headaches later.

What Delivery and Logistics Factors Matter Most?

Late deliveries can cost you customers and damage your reputation permanently.

Evaluate the supplier’s standard lead times, rush order capabilities, shipping methods, and inventory management. Choose suppliers offering 2-4 weeks standard delivery with emergency rush options and multiple shipping alternatives.

Delivery reliability affects every aspect of your business operations. Customers expect consistent delivery performance, and late shipments create cascading problems.

Understand standard lead times for different products. Simple connectors might ship in 1-2 weeks, while custom solutions require 4-6 weeks. Realistic suppliers provide accurate lead times based on their production schedules. Suppliers promising unrealistic delivery times usually miss deadlines.

Ask about rush order capabilities. Emergencies happen, and you need suppliers who can handle urgent requests. Good suppliers maintain some production capacity for rush orders. They clearly explain rush order fees and realistic timeframes. Suppliers claiming they can always rush orders often overpromise.

Evaluate their shipping options. Professional suppliers work with multiple freight companies and offer various shipping methods. They help optimize shipping costs based on your urgency and budget requirements. Limited shipping options indicate smaller, less professional operations.

Check their inventory management practices. Suppliers maintaining the stock of common items can ship faster. Ask about their inventory levels for products you order regularly. Suppliers with good inventory management reduce their supply chain risks.

Conclusion

This comprehensive supplier evaluation framework transforms your supplier selection from risky guesswork into confident decision-making. By systematically evaluating quality standards, production capacity, pricing transparency, technical support, and delivery reliability, you protect your business reputation and build profitable long-term partnerships with suppliers who truly support your growth.