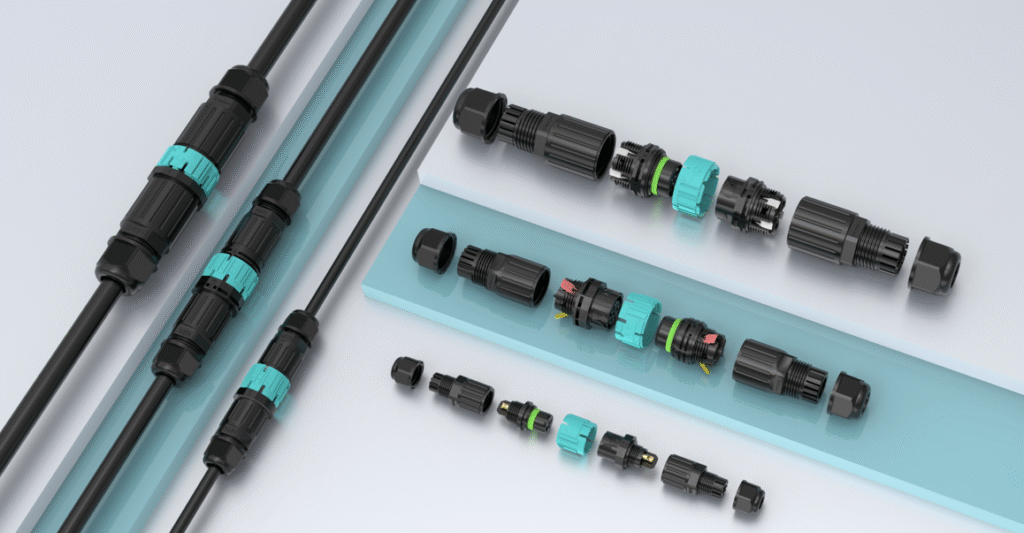

Water damage resulting from failed electrical connections costs businesses thousands of dollars in repairs annually. IP68 waterproof connectors provide the highest protection against water and dust ingress, rated for continuous submersion beyond 1 meter depth. These connectors feature advanced sealing systems and corrosion-resistant materials designed for harsh outdoor environments.

What Are IP68 Waterproof Connectors?

IP68 waterproof connectors are electrical connectors rated for continuous submersion in water beyond 1 meter depth. The IP (Ingress Protection) rating system defines protection levels against solid particles and liquids.

Key Features:

- Complete dust protection (rating 6)

- Waterproof for continuous submersion (rating 8)

- Temperature resistance from -40°C to +85°C

- Corrosion-resistant materials

- Multiple sealing mechanisms

Common Applications:

- Marine equipment connections

- Outdoor LED lighting systems

- Solar panel installations

- Underground electrical systems

- Pool and fountain equipment

IP67 vs IP68: Key Differences

Understanding the difference between IP67 and IP68 ratings is crucial for selecting the right connector for your application.

| Feature | IP67 | IP68 |

|---|---|---|

| Submersion Depth | Up to 1 meter | Beyond 2 meters (manufacturer specified) |

| Submersion Time | 30 minutes maximum | Continuous operation |

| Cost | Lower | Higher |

| Best Use | Temporary water exposure | Permanent underwater installations |

When to Choose IP68:

- Marine environments with saltwater exposure

- Continuous underwater operation

- Extreme weather conditions

- Long-term outdoor installations

When IP67 is Sufficient:

- Occasional rain exposure

- Indoor applications with washdown requirements

- Budget-conscious projects

- Short-term outdoor use

Installation Best Practices

Proper installation determines whether an IP68 connector provides IP68 protection. Follow these critical steps:

1. Surface Preparation

- Clean all threads and surfaces thoroughly

- Inspect for damage or debris

- Use appropriate cleaning solvents

2. Cable Preparation

- Strip wire insulation to exact specifications

- Avoid damaging conductor strands

- Use recommended stripping tools

3. Assembly Torque

- Use a calibrated torque wrench

- Follow the manufacturer’s specifications

- Avoid over-tightening that damages seals

4. Environmental Considerations

- Install in appropriate weather conditions

- Avoid direct sunlight during assembly

- Allow proper curing time for sealants

5. Testing

- Pressure test with compressed air

- Check for leaks using soapy water

- Verify electrical continuity

Cable Compatibility Guide

IP68 connectors accommodate cable diameters from 4mm to 12mm using specialized sealing grommets. Cable selection affects sealing effectiveness and system performance.

Cable Types and Applications:

Two-Core Cables (DC Applications)

- Diameter: 4-8mm

- Current Rating: 5-17.5 amps

- Best For: LED lighting, sensors, DC power

Three-Core Cables (AC Applications)

- Diameter: 5-10mm

- Current Rating: 10-41 amps

- Best For: Motor controls, AC lighting, equipment power

Armored Cables (Heavy Duty)

- Diameter: 8-12mm

- Current Rating: 30-50 amps

- Best For: Underground burial, high-stress environments

Cable Selection Tips:

- Match cable diameter to connector specifications

- Consider temperature rating requirements

- Choose UV-resistant materials for outdoor use

- Verify chemical compatibility with the environment

Wire Gauge and Current Ratings

Proper wire gauge selection depends on current load, voltage drop limits, and ambient temperature conditions. Undersized wires create resistance heating that accelerates connector failure.

Current Rating Guidelines:

| Current Range | Wire Gauge (AWG) | Typical Applications |

|---|---|---|

| 5-10 Amps | 18-22 AWG | LED lighting, sensors, controls |

| 15-25 Amps | 14-16 AWG | Motor controls, heating elements |

| 30-60 Amps | 10-12 AWG | Power distribution, large motors |

| 75-120 Amps | 6-8 AWG | Main feeders, EV charging |

Voltage Drop Considerations:

- Calculate the voltage drop for long cable runs

- Use a larger wire gauge for 250V/450V systems

- Consider ambient temperature derating

- Account for bundling with other cables

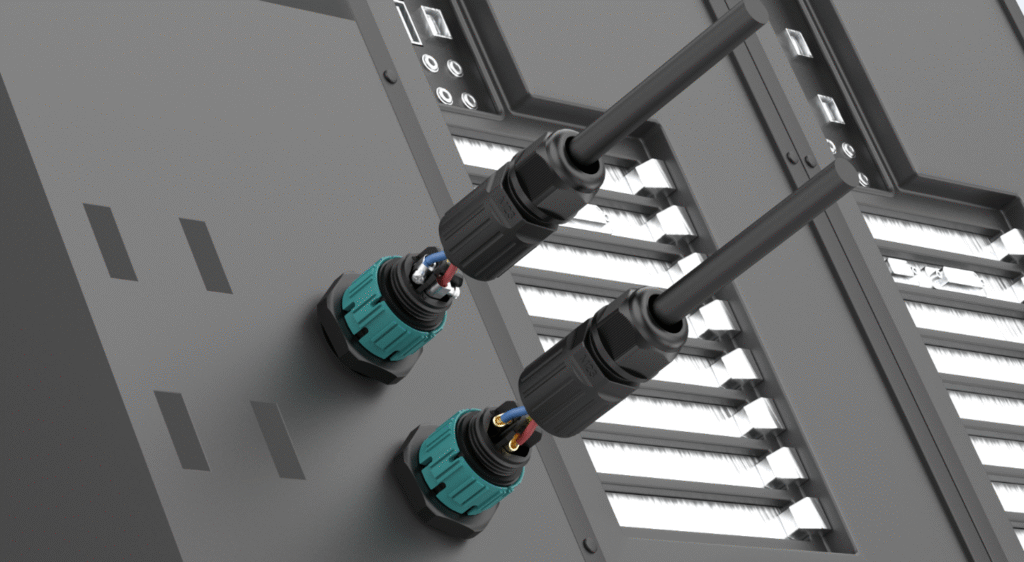

Panel Mount vs Cable-to-Cable

Choose the right mounting style based on your application requirements and maintenance needs.

Panel Mount Connectors

Advantages:

- Strong mechanical connection

- Enclosure provides additional protection

- Lower cost for permanent installations

- Simplified sealing requirements

Best For:

- Equipment interfaces

- Permanent installations

- Control panel connections

- Main power feeds

Cable-to-Cable Connectors

Advantages:

- Field serviceable connections

- Flexible routing options

- No enclosure access required

- Easier maintenance

Best For:

- Temporary connections

- Field maintenance scenarios

- Modular systems

- Extension cables

Testing Standards

IEC 60529 defines IP rating test procedures, including continuous submersion testing at specified depths and durations. Additional standards ensure comprehensive performance validation.

Key Testing Standards:

IEC 60529 (IP Rating Verification)

- Purpose: Validate the ingress protection rating

- Test Method: Continuous submersion at specified depth

- Pass Criteria: No water ingress, maintain electrical continuity

IEC 60068-2-11 (Salt Spray Resistance)

- Purpose: Assess corrosion resistance

- Test Method: 5% salt solution fog exposure

- Pass Criteria: No visible corrosion after the specified duration

IEC 60068-2-14 (Temperature Cycling)

- Purpose: Verify thermal stability

- Test Method: -40°C to +85°C cycles

- Pass Criteria: Maintain electrical specifications

What to Look For:

- Third-party laboratory certificates

- Test reports with specific conditions

- Long-term reliability data

- Environmental stress testing results

Frequently Asked Questions

How long do IP68 connectors last outdoors?

Quality IP68 connectors typically last 10-20 years in outdoor applications with proper installation and maintenance.

Can IP68 connectors be submerged permanently?

Yes, IP68 connectors are designed for continuous submersion, unlike IP67, which is rated for temporary immersion only.

What’s the maximum depth for IP68 connectors?

Maximum depth varies by manufacturer, typically ranging from 1-10 meters. Check specifications for your specific application.

Do IP68 connectors require special tools for installation?

Basic installation requires standard tools, but calibrated torque wrenches are recommended for critical applications.

How do I maintain IP68 connectors?

Perform regular visual inspections, clean external surfaces, and check for signs of corrosion or damage. Replace seals as recommended by the manufacturer.

Conclusion

IP68 waterproof connectors provide essential protection for outdoor electrical systems. By understanding IP ratings, proper installation techniques, and compatibility requirements, you can select connectors that deliver reliable performance for decades.

Key takeaways:

- Choose IP68 for continuous underwater applications

- Follow proper installation procedures for maximum protection

- Match cable specifications to connector requirements

- Select appropriate current ratings for your load

- Verify performance through standardized testing

For high-quality IP68 waterproof connectors and expert technical support, contact AGX Connector today. Our experienced team can help you select the right connectors for your specific application requirements.