Fast Installation | High Quality | Factory Direct

Push-In Wire Connectors

- Fast, Safe, Certified

- Tool-Free Installation - Push-in connection, fast and easy

- Transparent Housing - Visual wire insertion check

- Up to 50A Current - Heavy-duty power transmission

- TÜV/UL/CE Certified - International quality standards

- Factory Direct - Best price, flexible MOQ

- Quick Delivery - 5-7 days, stable supply

Push Wire Connector Supplier & Manufacturer

Founded in 2016, AGX® is a leading push wire connector manufacturer in China, specializing in tool-free electrical connectors from 2-pole to 8-pole configurations with current ratings up to 50A. All our push wire connectors are CE, RoHS, TÜV, UL certified, ensuring reliable performance and safety compliance for global markets. We offer customized solutions, OEM & ODM services including logo printing and personalized packaging. Wholesalers, distributors, dealers, and traders are welcome to purchase in bulk with factory direct pricing and flexible MOQ options.

What Are Push-in Wire Connectors?

Why Choose AGX Push Wire Connectors?

Tool-Free Installation

Simply insert, push, and connect—no screwdrivers, stripping tools, or wire nuts required. Save time and simplify wiring for electricians and DIY users alike.

Wide Temperature Range

Premium Material Construction

Secure & Reusable Connection

Universal Compatibility

Compact Space-Saving Design

Push Wire Connector in Various Applications

Our push wire connectors are trusted in diverse demanding applications:

Building Wiring

Lighting Installations

Socket and Switch

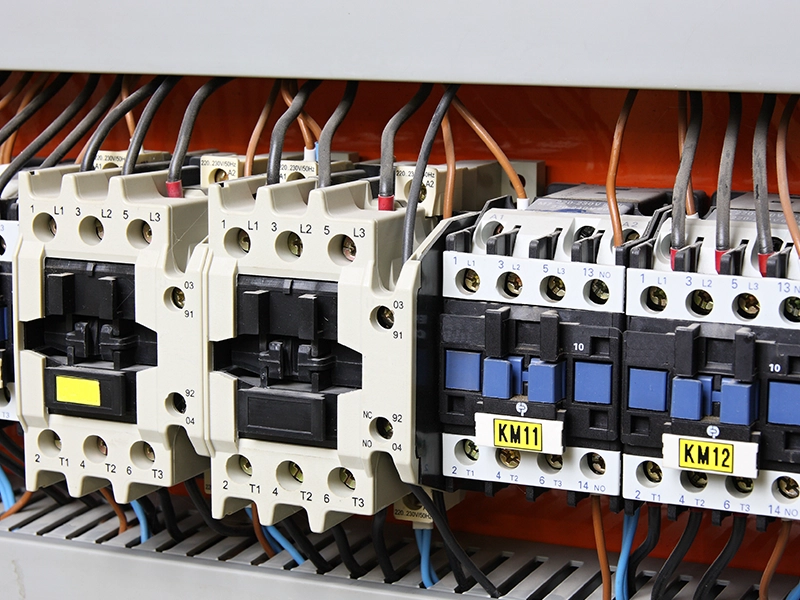

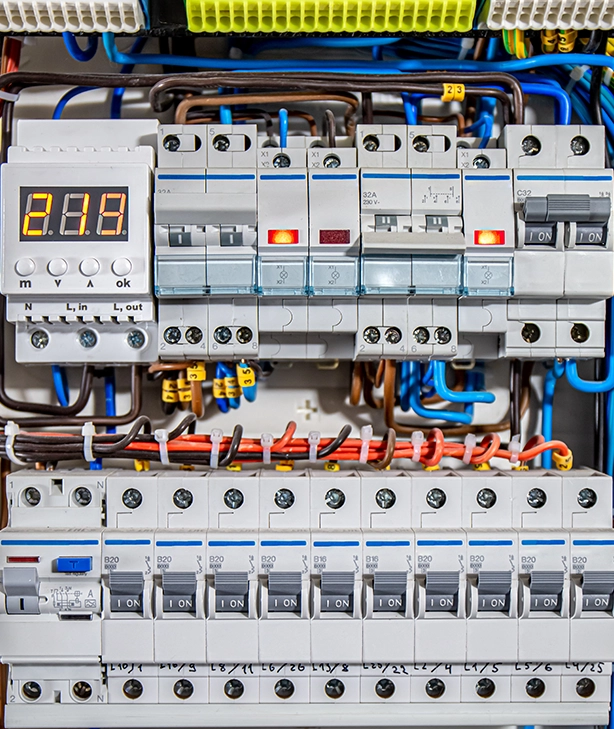

Industrial Electrical Wire Connections

Automotive Wiring

Outdoor Lighting

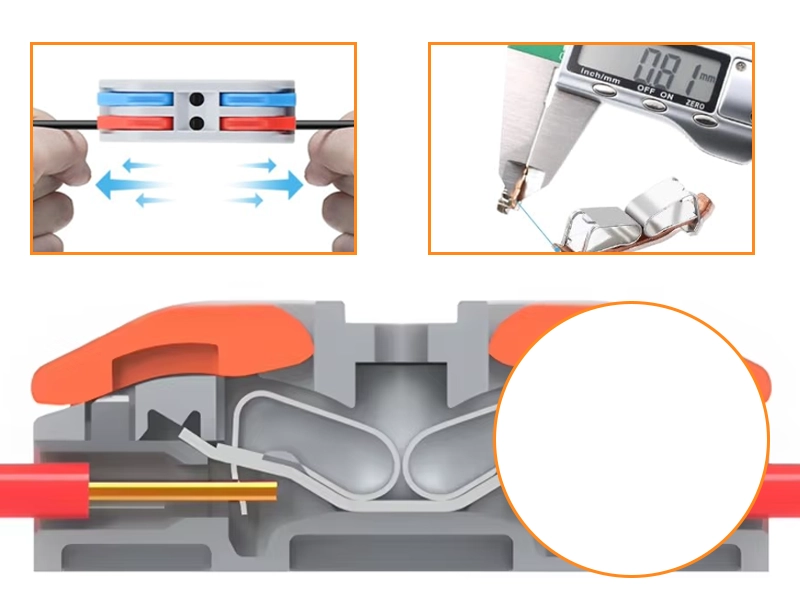

How We Manufacture Push Wire Connectors?

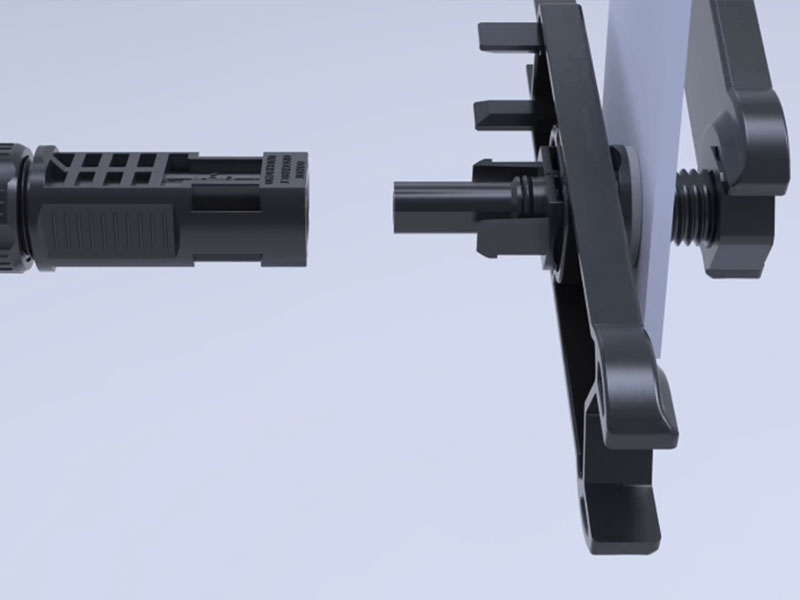

R&D and Design

Our engineering team designs connectors using CAD software based on your requirements. We optimize the male plug and female socket for a perfect fit, low contact resistance, and easy mating. Everything is tested virtually before we make a single part – saving you time and money.

Mold Development and Manufacturing

Injection Molding Production

Metal Component Manufacturing

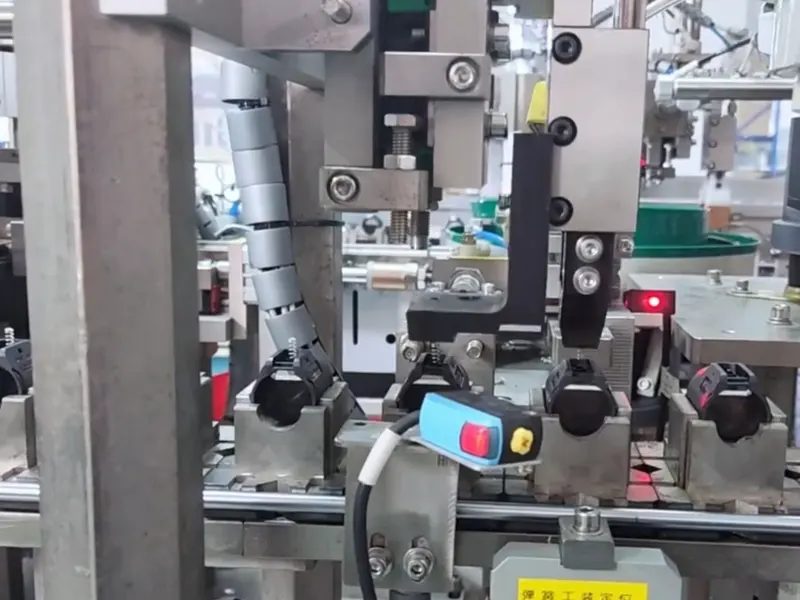

Component Assemblyt

Final Assembly

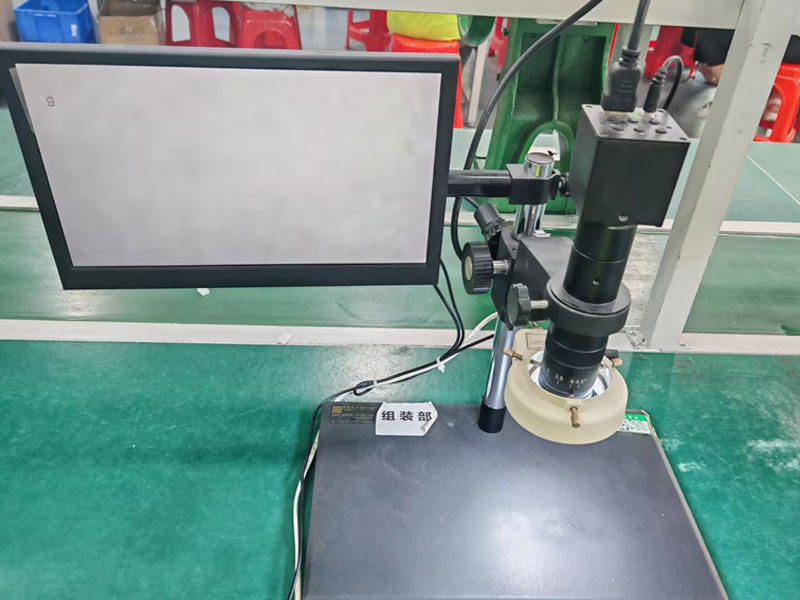

Quality Inspection

Professional Packaging

Finished Product Warehouse

How to Use Push-in Wire Connectors?

Step-by-Step Installation Guide

1. Turn Off Power

2. Strip the Wire

3. Insert the Wire

4. Automatic locking

5. Verify the Connection

6. Test Security

Tips:

- Use correct connector size for wire gauge

- Twist stranded wires slightly before inserting

- Always verify power is off before starting

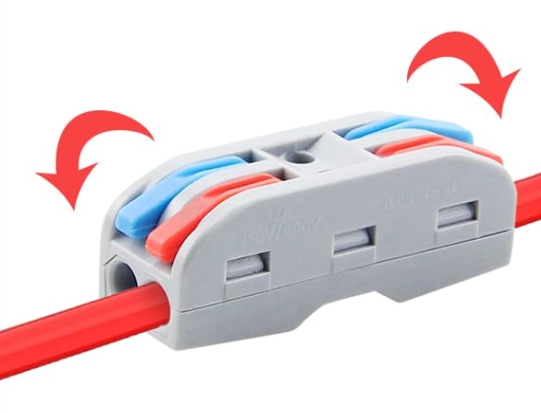

Disconnection Process: For reusable connectors, wires can be removed by twisting the connector left and right while pulling, or by using a release mechanism such as a lever or button, depending on the connector design.

RPush Wire Connector Solutions:

Customer Success Stories

Case Study:

30-Year Belgian Distributor Cuts Installation Time by 60%

Van den Berg Electrical Supply N.V. | Antwerp, Belgium

Leading electrical distributor serving 150+ contractors across Benelux region since 1994

-

Challenge:

Contractor customers faced rising labor costs and tight deadlines. Traditional wire nuts consumed excessive time in junction box installations. -

The Solution:

Implemented AGX KC-6601 series push-in connectors across contractor network with hands-on training and full product range support. - Key Results:

- 60% faster installation vs. traditional wire nuts

- 40% space savings in junction boxes

- €200,000+ labor cost savings across the network

- Zero connection failures in 18 months

- 35% YoY sales growth in connector category

CASE STUDY:

Canadian Manufacturer Reduces Lead Times from 4 Weeks to 10 Days

Precision Controls Inc. | Toronto, Canada

Industrial control panel manufacturer serving automotive and food processing sectors since 1991

-

Challenge:

Assembly bottlenecks created 3-4 week lead times. Automotive clients demanded 2-week delivery. Inconsistent screw terminal connections cause quality issues. -

Solution:

Replaced screw terminals with AGX KC-6608 DIN-rail connectors in 80% of standard panel designs. Trained assembly team and developed custom configurations for repeated applications. - Key Results:

- 50% reduction in wiring time per panel

- Lead times cut to 10-12 days (from 3-4 weeks)

- 98% first-pass quality rate (up from 92%)

- 40% production capacity increase without adding staff

- 3 new automotive accounts won on delivery performance

Wholesale Push Wire

Connector by Series

Push Wire Connector Product List

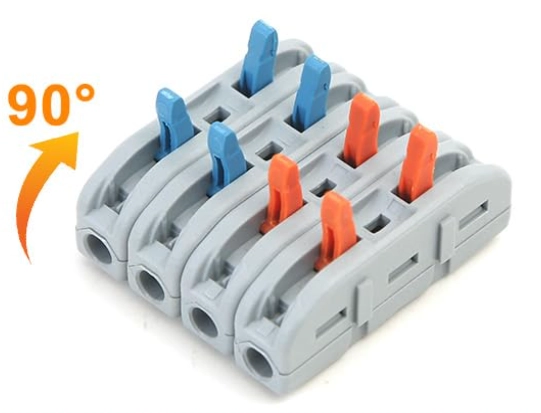

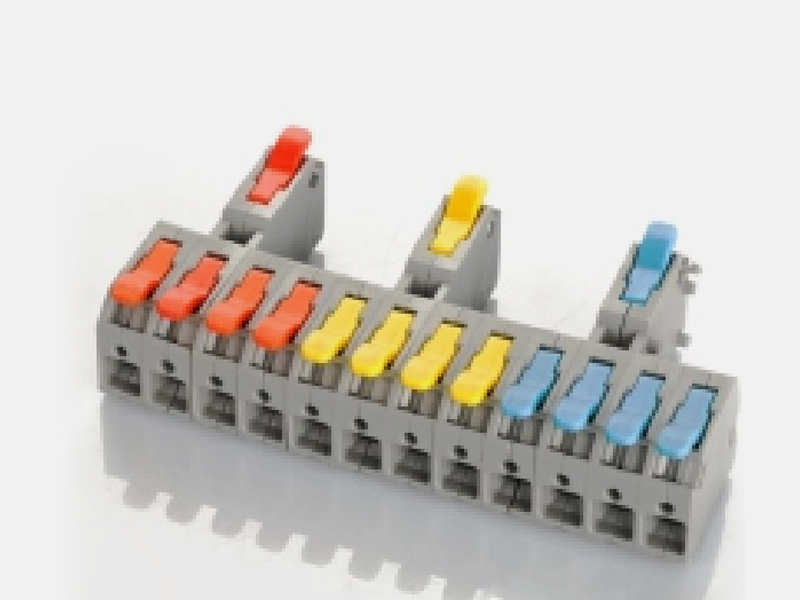

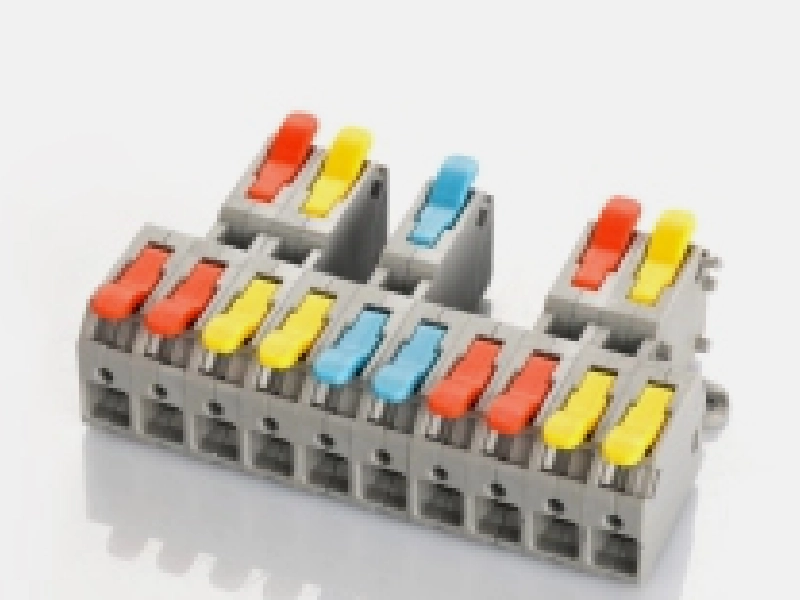

KC-6601 Series (Fixed-Ear Splitter Terminal)

| Model | Ports | Total Positions | Wire Range | Dimensions L×W×H (mm) | Voltage | Current | Mounting Type | Key Features | Applications |

|---|---|---|---|---|---|---|---|---|---|

| KC-6601-2-4 | 2 | 4 | 0.5-6mm² (20-10 AWG) | 30×48×21.6 | 450V | 40A | Fixed ears | Panel mount, transparent housing | Small junction boxes |

| KC-6601-2-6 | 2 | 6 | 0.5-6mm² (20-10 AWG) | 45×48×21.6 | 450V | 40A | Fixed ears | Panel mount, transparent housing | Distribution panels |

| KC-6601-2-8 | 2 | 6 | 0.5-6mm² (20-10 AWG) | 60×48×21.6 | 450V | 40A | Fixed ears | Panel mount, transparent housing | Power distribution |

| KC-6601-2-10 | 2 | 10 | 0.5-6mm² (20-10 AWG) | 75×48×21.6 | 450V | 40A | Fixed ears | Panel mount, transparent housing | Large control panels |

| KC-6601-3-6 | 3 | 6 | 0.5-6mm² (20-10 AWG) | 45×48×21.6 | 450V | 40A | Fixed ears | Panel mount, transparent housing | 3-phase connections |

| KC-6601-3-9 | 3 | 9 | 0.5-6mm² (20-10 AWG) | 67.5×48×21.6 | 450V | 40A | Fixed ears | Panel mount, transparent housing | Multi-circuit systems |

| KC-6601-3-12 | 3 | 12 | 0.5-6mm² (20-10 AWG) | 90×48×21.6 | 450V | 40A | Fixed ears | Panel mount, transparent housing | Complex wiring |

| KC-6601-3-15 | 3 | 15 | 0.5-6mm² (20-10 AWG) | 112.5×48×21.6 | 450V | 40A | Fixed ears | Panel mount, transparent housing | High-density panels |

| KC-6601-4-8 | 4 | 8 | 0.5-6mm² (20-10 AWG) | 60×48×21.6 | 450V | 40A | Fixed ears | Panel mount, transparent housing | Multi-branch circuits |

| KC-6601-4-12 | 4 | 12 | 0.5-6mm² (20-10 AWG) | 90×48×21.6 | 450V | 40A | Fixed ears | Panel mount, transparent housing | Industrial distribution |

| KC-6601-5-10 | 5 | 10 | 0.5-6mm² (20-10 AWG) | 75×48×21.6 | 450V | 40A | Fixed ears | Panel mount, transparent housing | Complex routing |

| KC-6601-5-15 | 5 | 15 | 0.5-6mm² (20-10 AWG) | 112.5×48×21.6 | 450V | 40A | Fixed ears | Panel mount, transparent housing | Heavy-duty applications |

KC-6601-2-4

KC-6601-2-6

KC-6601-2-8

KC-6601-2-10

KC-6601-3-6

KC-6601-3-9

KC-6601-3-12

KC-6601-3-15

KC-6601-4-8

KC-6601-4-12

KC-6601-5-10

KC-6601-5-15

Product Video

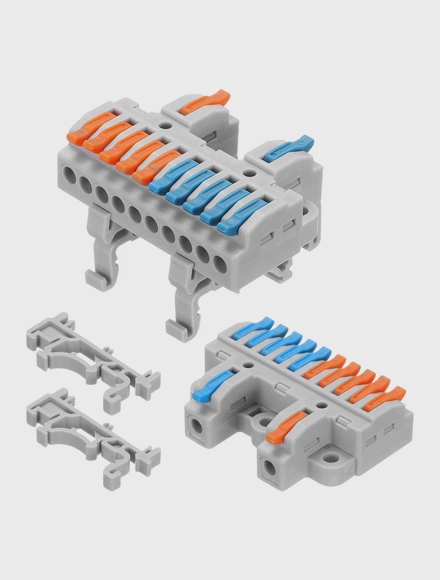

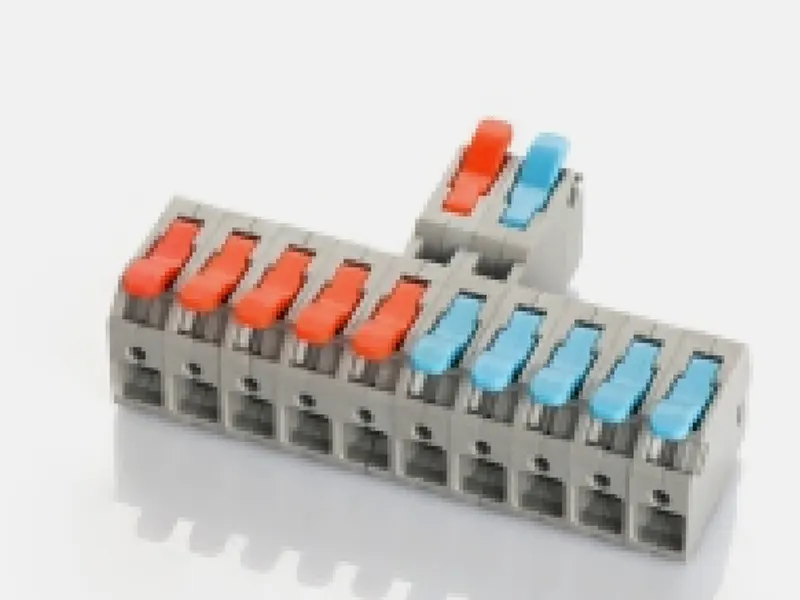

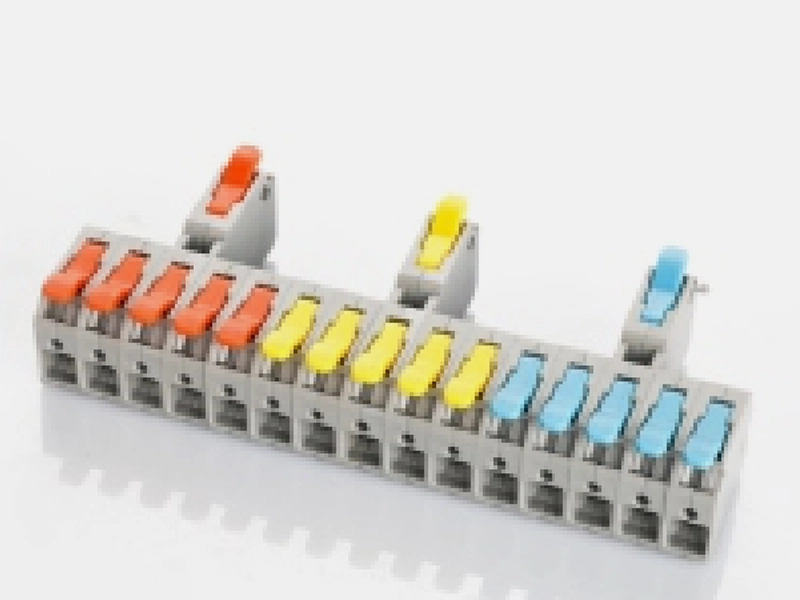

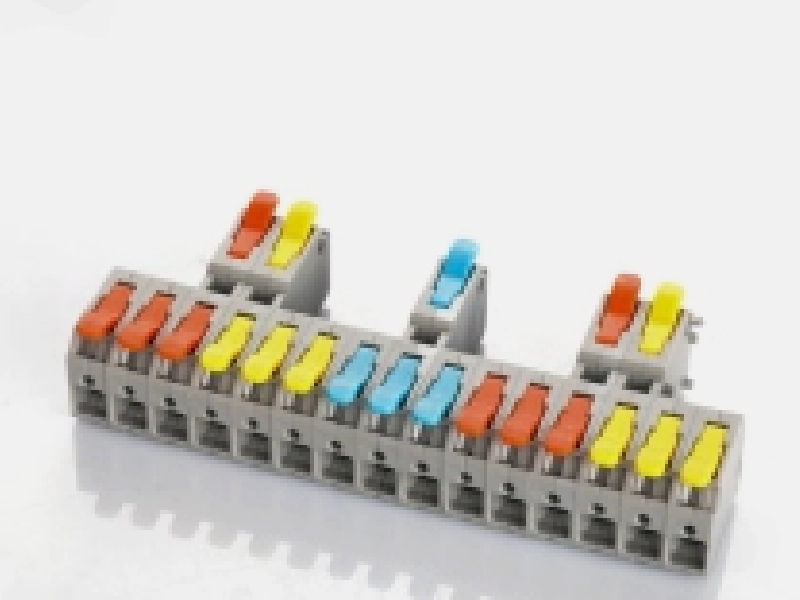

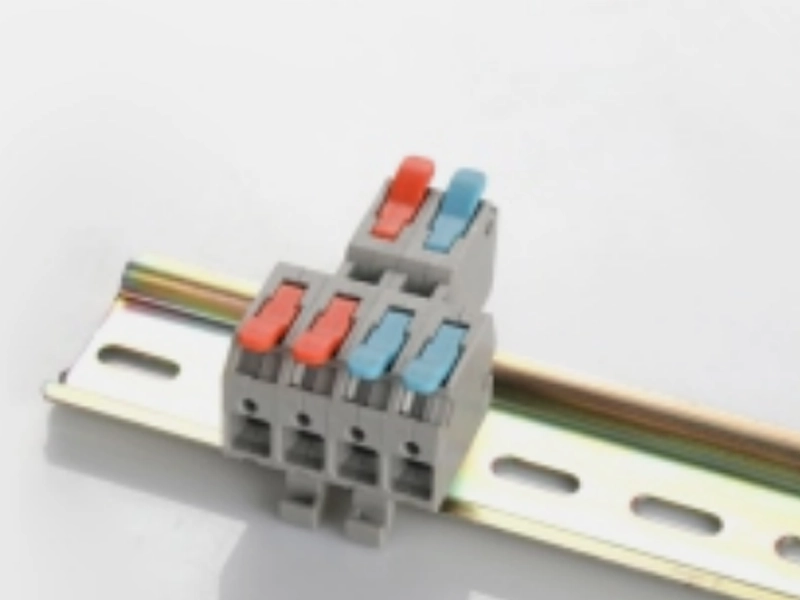

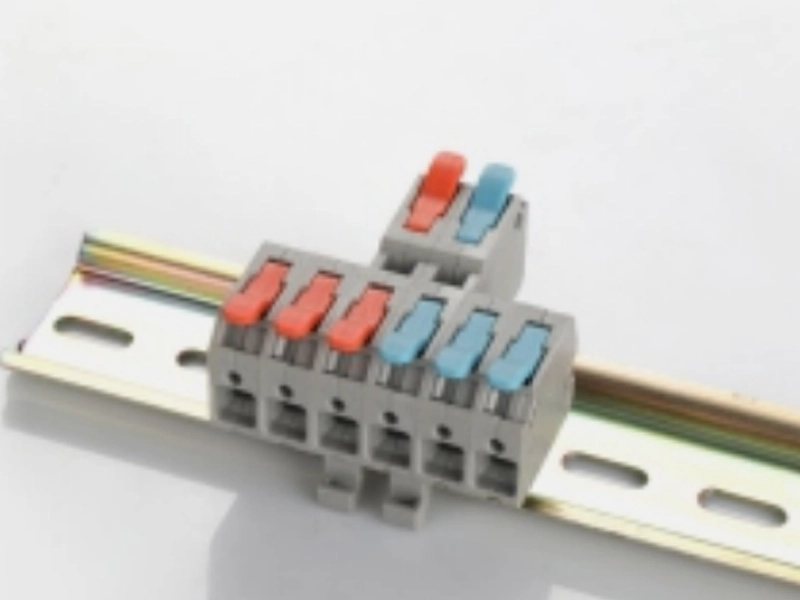

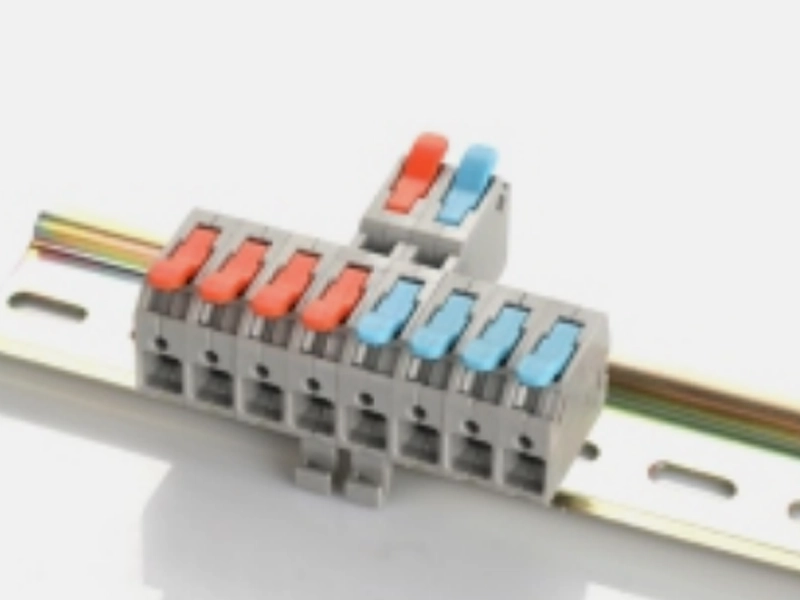

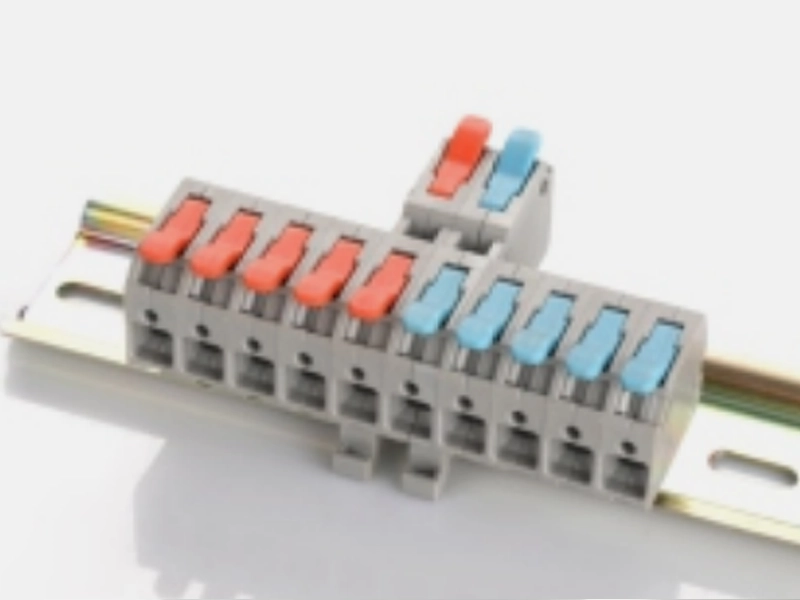

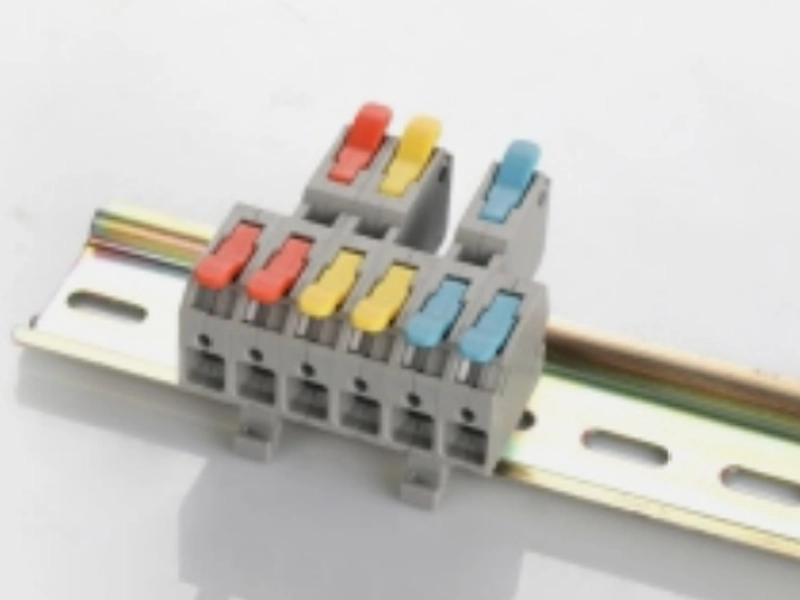

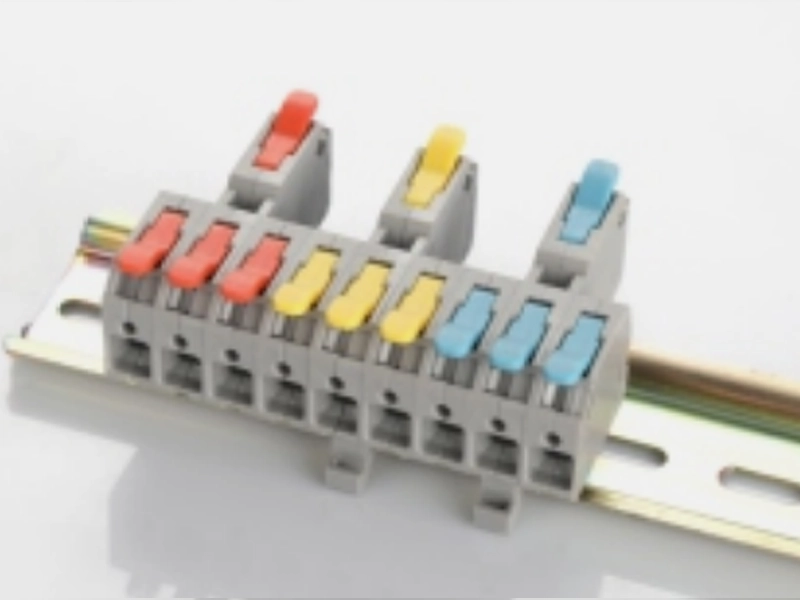

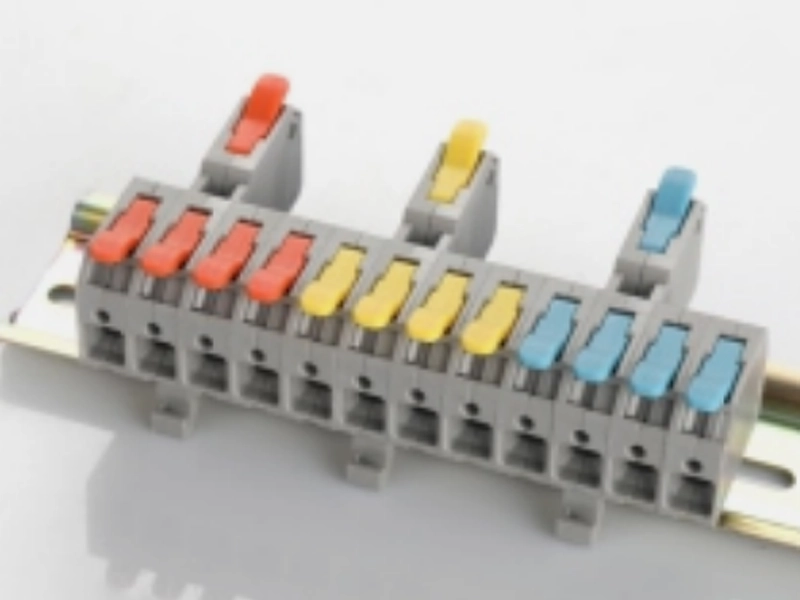

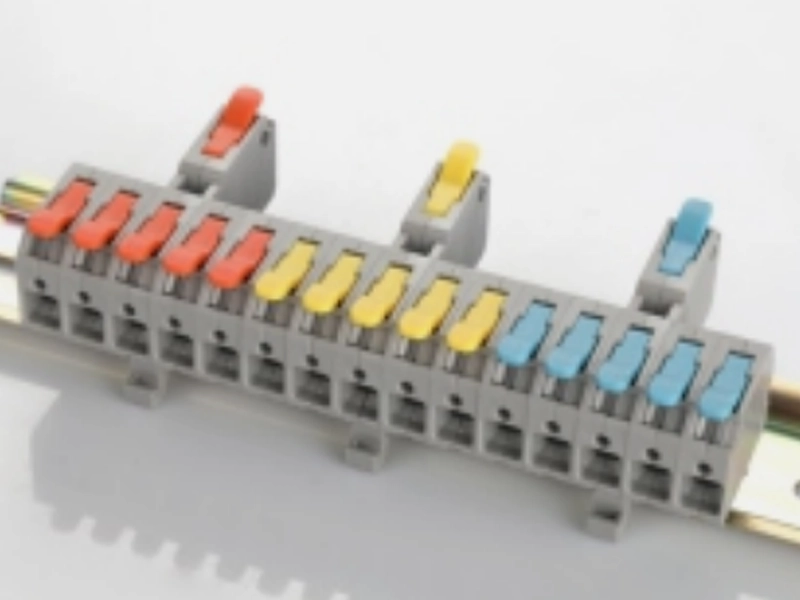

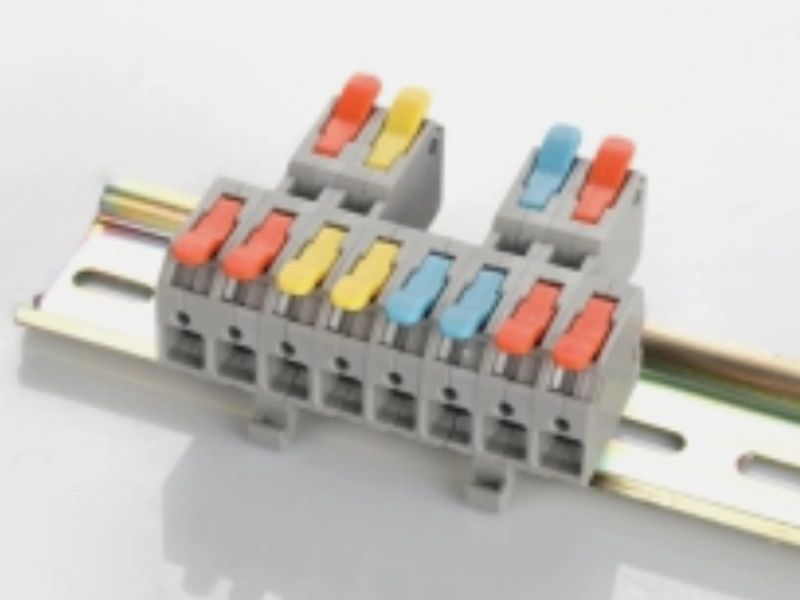

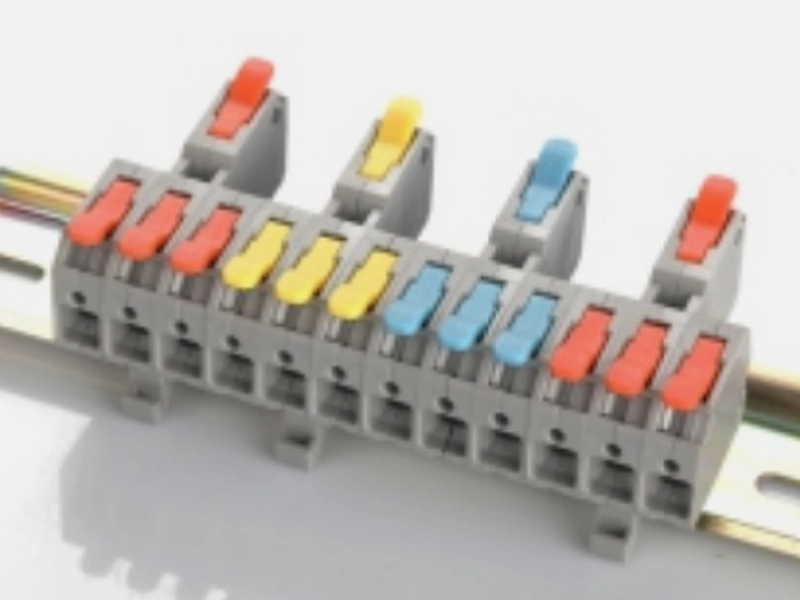

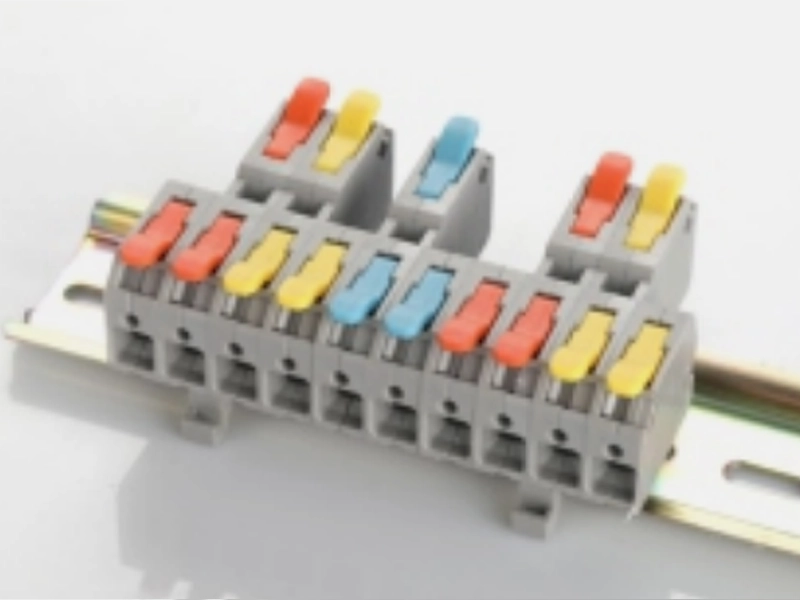

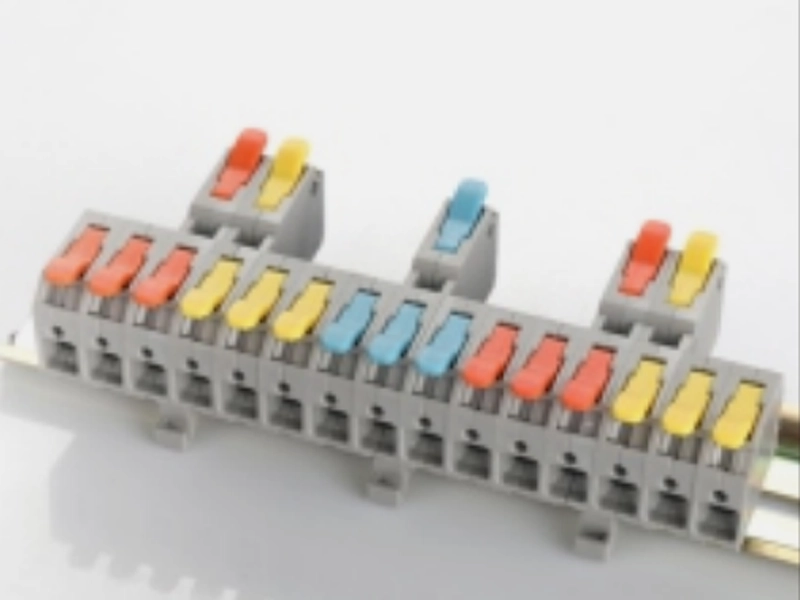

KC-6601-D Series (DIN-Rail Type Splitter Terminal)

| Model | Ports | Total Positions | Wire Range | Dimensions L×W×H (mm) | Voltage | Current | Mounting Type | Key Features | Applications |

|---|---|---|---|---|---|---|---|---|---|

| KC-6601-2-4D | 2 | 4 | 0.5-6mm² (20-10 AWG) | 30×48×32.6 | 450V | 40A | DIN rail 35mm | Snap-on, tool-free | Control cabinets |

| KC-6601-2-6D | 2 | 6 | 0.5-6mm² (20-10 AWG) | 45×48×32.6 | 450V | 40A | DIN rail 35mm | Snap-on, tool-free | Automation systems |

| KC-6601-2-8D | 2 | 6 | 0.5-6mm² (20-10 AWG) | 60×48×32.6 | 450V | 40A | DIN rail 35mm | Snap-on, tool-free | Distribution boxes |

| KC-6601-2-10D | 2 | 10 | 0.5-6mm² (20-10 AWG) | 75×48×32.6 | 450V | 40A | DIN rail 35mm | Snap-on, tool-free | Industrial panels |

| KC-6601-3-6D | 3 | 6 | 0.5-6mm² (20-10 AWG) | 45×48×32.6 | 450V | 40A | DIN rail 35mm | Snap-on, tool-free | 3-phase systems |

| KC-6601-3-9D | 3 | 9 | 0.5-6mm² (20-10 AWG) | 67.5×48×32.6 | 450V | 40A | DIN rail 35mm | Snap-on, tool-free | PLC connections |

| KC-6601-3-12D | 3 | 12 | 0.5-6mm² (20-10 AWG) | 90×48×32.6 | 450V | 40A | DIN rail 35mm | Snap-on, tool-free | Machine wiring |

| KC-6601-3-15D | 3 | 15 | 0.5-6mm² (20-10 AWG) | 112.5×48×32.6 | 450V | 40A | DIN rail 35mm | Snap-on, tool-free | Complex automation |

| KC-6601-4-8D | 4 | 8 | 0.5-6mm² (20-10 AWG) | 60×48×32.6 | 450V | 40A | DIN rail 35mm | Snap-on, tool-free | Multi-line distribution |

| KC-6601-4-12D | 4 | 12 | 0.5-6mm² (20-10 AWG) | 90×48×32.6 | 450V | 40A | DIN rail 35mm | Snap-on, tool-free | High-density wiring |

| KC-6601-5-10D | 5 | 10 | 0.5-6mm² (20-10 AWG) | 75×48×32.6 | 450V | 40A | DIN rail 35mm | Snap-on, tool-free | Complex circuits |

| KC-6601-5-15D | 5 | 15 | 0.5-6mm² (20-10 AWG) | 112.5×48×32.6 | 450V | 40A | DIN rail 35mm | Snap-on, tool-free | Industrial distribution |

KC-6601-2-4D

KC-6601-2-6D

KC-6601-2-8D

KC-6601-2-10D

KC-6601-3-6D

KC-6601-3-9D

KC-6601-3-12D

KC-6601-3-15D

KC-6601-4-8D

KC-6601-4-12D

KC-6601-5-10D

KC-6601-5-15D

Product Video

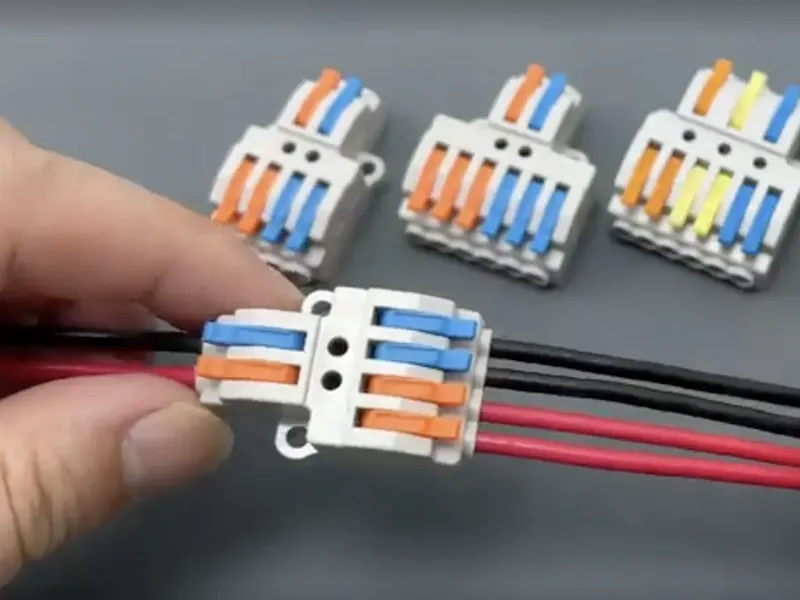

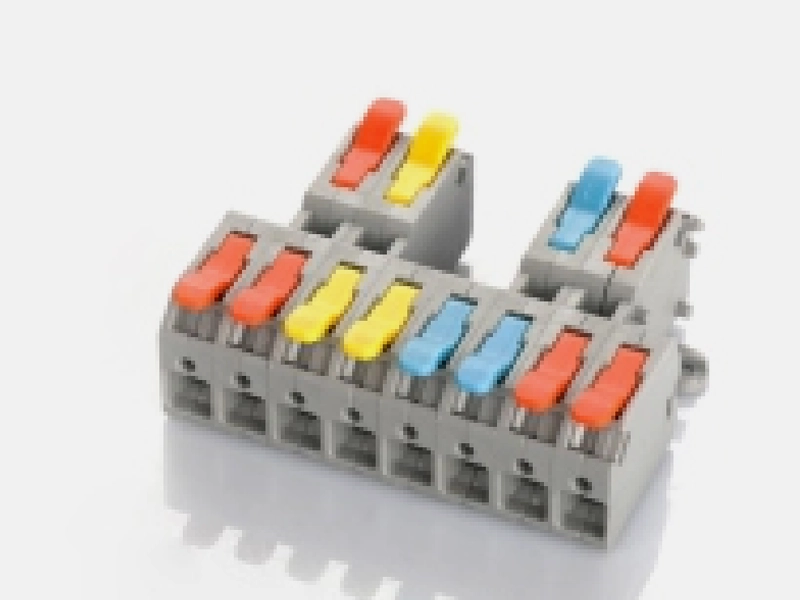

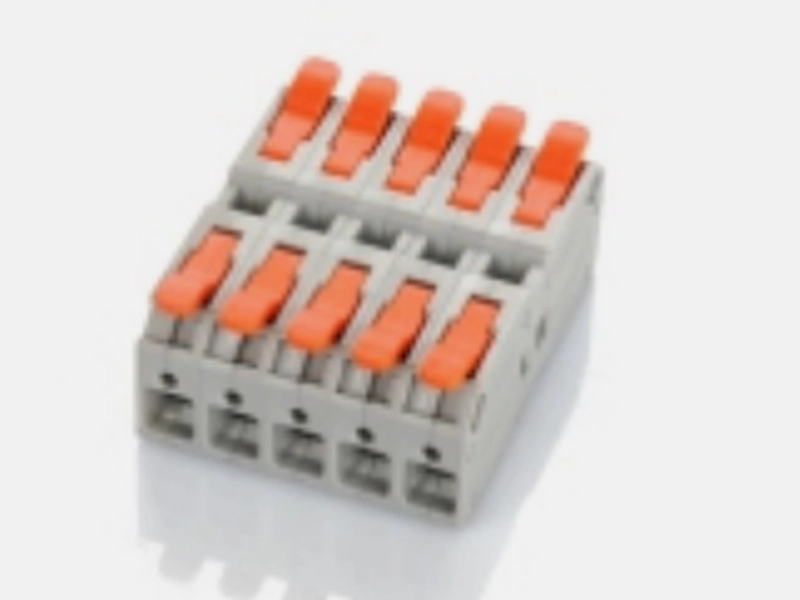

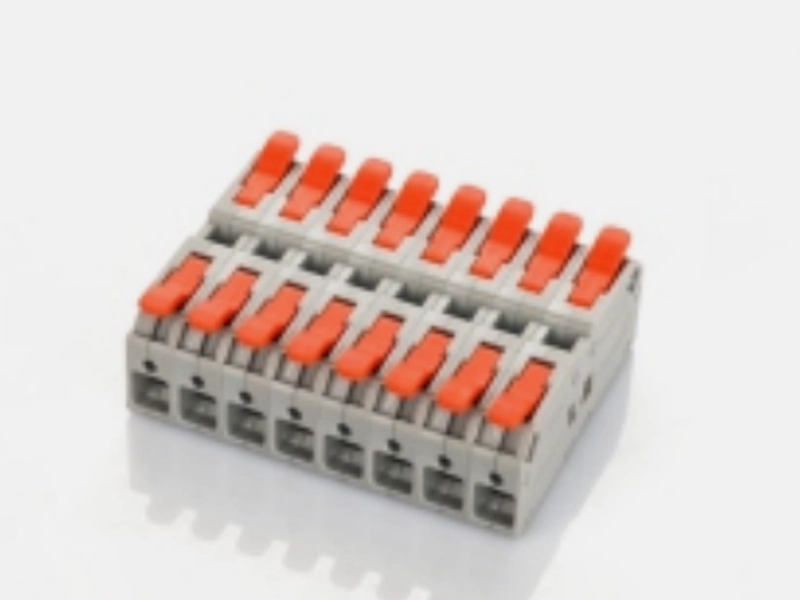

KC-6608 Series (Lever-Actuated Compact Connectors)

| Model | Ports | Wire Range | Dimensions L×W×H (mm) | Voltage | Current | Wire Types | Key Features | Reusable | Applications |

|---|---|---|---|---|---|---|---|---|---|

| KC-6608-2 | 2 | 0.5-6mm² (24-10 AWG) | 32×15×18 | 450V | 32A | Solid/Stranded | Lever operation, transparent | Yes (30+ cycles) | Lighting, receptacles |

| KC-6608-3 | 3 | 0.5-6mm² (24-10 AWG) | 37×15×24 | 450V | 32A | Solid/Stranded | Lever operation, transparent | Yes (30+ cycles) | 3-way switches |

| KC-6608-4 | 4 | 0.5-4mm² (24-12 AWG) | 42×15×31 | 450V | 24A | Solid/Stranded | Lever operation, transparent | Yes (30+ cycles) | Junction boxes, HVAC |

| KC-6608-5 | 5 | 0.5-4mm² (24-12 AWG) | 47×15×38 | 450V | 24A | Solid/Stranded | Lever operation, transparent | Yes (30+ cycles) | Complex circuits |

| KC-6608-8 | 8 | 0.5-2.5mm² (24-14 AWG) | 62×15×59 | 450V | 20A | Solid/Stranded | Lever operation, transparent | Yes (30+ cycles) | Distribution, industrial |

KC-6608-2

KC-6608-3

KC-6608-4

KC-6608-5

KC-6608-8

Product Video

Custom Push Wire Connector

- Male & Female Connectors: Precision-engineered housings with secure locking mechanisms for reliable solar panel connections.

- Metal Contacts & Seals Corrosion-resistant pins and sockets with premium EPDM rubber seals ensuring IP67 waterproof protection.

- UV-Resistant Housing Durable thermoplastic construction withstands decades of outdoor exposure and environmental stress.

Why Wholesale Push Wire Connectors in Bulk from us?

Professional Manufacturing

AGX specializes in push wire connectors and cable assemblies with years of industry expertise. We focus on stable performance, precision engineering, and long product lifespan.

Certified Quality

We provide rigorously tested products that pass TÜV, ULSAA, and CE certifications, ensuring IP68-rated protection you can trust in any environment.

Customization

We have a professional R&D team of 15 members. If you have specific requirements for your project, we are always here to help you. We manufacture and customize molds that require particular dimensions and accessories.

Flexible MOQ

We offer flexible minimum order quantities to meet the real needs of your project. Our minimum order quantities start at a relatively low, giving you the highest flexibility in the testing market.

Competitive Price

When you choose AGX as your push wire connector supplier and buy in bulk, you will benefit from our competitive wholesale prices.

Fast Delivery

Our team of 200+ experienced workers and automated production lines ensure your orders move quickly from manufacturing to your facility.Our team of 200+ experienced workers and automated production lines ensure your orders move quickly from manufacturing to your facility.

Free Sample

We provide free samples for testing and project compatibility evaluation, with same-day processing and shipment within 24 hours. This allows you to quickly assess our product quality and ensure perfect fit for your specific application before placing bulk orders.

Trusted by Global Brands

Our waterproof connectors are widely used in LED lighting, solar systems, marine, automotive, and industrial automation, earning long-term partnerships with OEM clients worldwide.

Product Testing

All of our push-in wire connectors are not mass-produced until they have gone through multiple rigorous testing steps in our laboratory equipment. This ensures high performance and stability and the product’s long life.

Automatic Insertion and Extraction Tester

Temperature rise

current tester

Voltage Tester

Horizontal plug-in test

DC Resistance + Insulation Resistance Tester

IP68 Waterproof Tester

Scorch Wire Tester

Leakage Trace Tester

Horizontal Vertical F

lame Tester

Constant temperature and humidity tester

Certification & Patents

2025 Full Waterproof Connector Catalog

- Complete technical specifications

- Quality certificates & test reports

- Integration guidelines

- Compatibility charts

Free Sample Request

Perfect for: Technical Evaluation | System Integration Testing | Quality Assessment