The rain hammered against the factory windows like angry fists. Inside, water seeped through a faulty connector, and suddenly—darkness. Twenty thousand dollars of equipment, dead. All because someone saved fifty bucks on a cheap waterproof connector.

I’ve been in this business for 15 years, and I’ve witnessed this horror story unfold more times than I care to remember.

The top 10 IP68 waterproof connector manufacturers for industrial applications are TE Connectivity, Amphenol, Fischer Connectors, Binder, Anderson Power Products, Sunshine Connector, WEIPU, KINSUN, Tekox, and AGX. These companies specialize in dust-tight, submersion-resistant connectors that survive where others fail.

The IP68 Difference: Why Your Connectors Keep Failing

Picture this: You’re standing knee-deep in murky water, watching your production line grind to a halt. The IP65 connectors you bought? They’re as useful as a screen door on a submarine.

IP68 connectors provide complete dust protection and withstand continuous water immersion beyond 1 meter—indefinitely. Compare that to IP67’s measly 30-minute swim at 1 meter, or IP65’s pathetic splash resistance.

Here’s what those numbers mean:

| IP Rating | Dust Protection | Water Protection | Real-World Survival |

|---|---|---|---|

| IP65 | Dust protected | Water jets | Dies in heavy rain |

| IP67 | Dust tight | Brief submersion (1m, 30min) | Survives a puddle |

| IP68 | Dust tight | Continuous submersion (>1m) | Lives underwater |

| IP69K | Dust tight | High-pressure steam cleaning | Food industry champion |

The testing? Brutal. Fischer Connectors dunks their IP68 products 20 meters deep for 24 hours straight. That’s like parking your connector at the bottom of a swimming pool and coming back tomorrow—it better still work.

How to Choose Without Getting Burned (Again)

A client in Barcelona once called me, voice shaking. He’d installed 5,000 connectors in outdoor electrical boxes. The wrong ones. In Spain. Where it rains sideways.

Select manufacturers based on: industry certifications (UL, CE, RoHS), environmental resistance (temperature, chemicals), current capacity, and proven track record. Always test samples in your actual conditions—never trust spec sheets alone.

The Selection Matrix That Saves Lives (and Budgets)

| Your Environment | Critical Features | Materials That Survive | Manufacturers That Deliver |

|---|---|---|---|

| Marine/Offshore | Salt spray resistance, vibration dampening | 316L stainless steel, gold contacts | Fischer, Amphenol, AGX |

| Mining | Impact resistance, dust sealing | Reinforced thermoplastics, metal shells | Binder, TE Connectivity |

| Food Processing | FDA compliance, chemical resistance | Food-grade plastics, EPDM seals | Anderson Power, KINSUN |

| Solar Farms | UV stability, temperature cycling | UV-stabilized polymers, silicone | Sunshine, AGX LP Series |

The dirty secret? Most manufacturers only test once, in perfect lab conditions. The good ones—Fischer, Amphenol, AGX—they torture their products. Thermal shock from -55°C to +200°C. Salt fog for 1,000 hours. Vibration that would shake your teeth loose.

The Manufacturers That Deliver When It Matters

I stood on an oil rig in the North Sea, waves crashing 30 feet below. The engineer pointed to a connector caked in salt and grime. “Fifteen years,” he said. “Never failed once.”

Fischer Connectors, Amphenol, and TE Connectivity dominate harsh environments through military-grade testing and aerospace heritage. They’re expensive because they work when failure means disaster.

The Big Three’s Secret Weapons:

Fischer Connectors: Swiss precision meets military paranoia. Their Freedom Series uses a push-pull mechanism that seals tighter with each connection. Tested at 300 meters depth—that’s deeper than most submarines dive.

Amphenol: 90 years of not screwing up. Their Eco|Mate series handles data at 10Gbps while swimming. Global manufacturing means consistent quality, whether you buy in Boston or Bangkok.

TE Connectivity: The DEUTSCH brand survived everything from NASCAR crashes to Mars rovers. Their secret? Automotive-grade testing that assumes every connector will be abused by a gorilla with a wrench.

The Features That Separate Winners from Expensive Failures

A customer called at 2 AM. His LED display—a $50,000 installation—was flickering like a scene from a horror movie. The “waterproof” connectors? They forgot about strain relief. Water found its way in through the flexing cable.

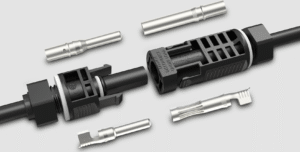

Essential IP68 features: Multi-stage sealing, integrated strain relief, corrosion-resistant plating, 500+ mating cycles, field serviceability, and temperature ratings 20°C above your worst-case scenario.

The Anatomy of a Connector That Won’t Let You Down:

| Component | Cheap Version | Professional Grade | What Happens When You Skimp |

|---|---|---|---|

| Sealing | Single O-ring | Triple-seal system | Water finds a way |

| Contacts | Tin-plated brass | Gold-plated copper alloy | Corrosion = connection death |

| Housing | Generic plastic | UV-stable, flame-retardant polymer | Cracks, melts, or both |

| Strain Relief | Basic grip | Integrated cable gland | Cables pull out, water gets in |

| Locking | Simple threads | Push-pull with safety lock | Vibration = disconnection |

Chinese vs. Western Manufacturers: The Truth Nobody Tells You

Every procurement manager asks the same question: “Can Chinese manufacturers compete with European quality?”

Leading Chinese manufacturers like AGX, KINSUN, and Sunshine now match Western quality at 30-50% lower prices. European brands still dominate extreme applications, but the gap is closing fast.

The Real Comparison (Based on 15 Years in the Trenches):

| Factor | Chinese Leaders | European/US Giants | AGX’s Sweet Spot |

|---|---|---|---|

| Price | 30-50% lower | Premium pricing | Fair pricing for real quality |

| Quality | Excellent (top tier) | Excellent | Matches or exceeds standards |

| Custom Options | Growing fast | Fully flexible | Personal engineering support |

| Technical Support | Improving | Comprehensive | Direct access to engineers |

| Delivery Speed | Lightning fast | 8-12 weeks | Flexible scheduling |

The truth? Companies like AGX learned from Western manufacturers, then improved the process. We use the same German injection molding machines, the same Japanese contact materials, but with leaner operations and direct customer relationships.

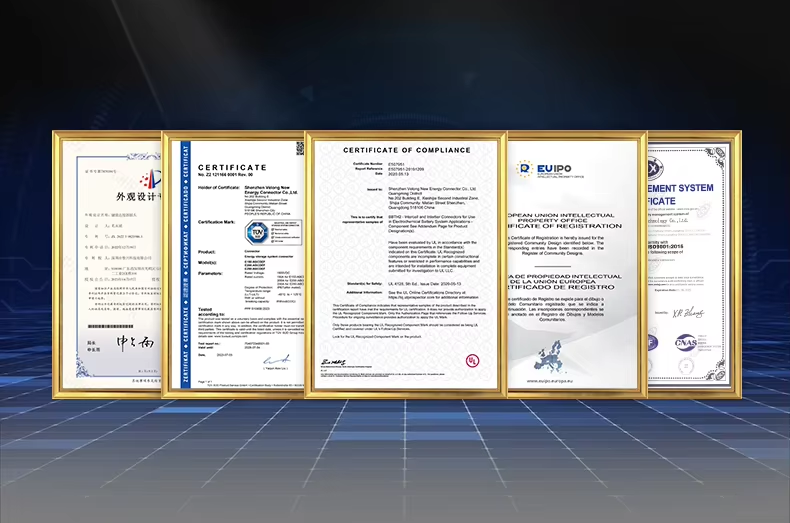

Certifications: Separating Real Testing from Pretty Paper

In a Shenzhen factory, I watched a manager proudly display his wall of certificates. Half were self-printed. The other half? Expired.

Mandatory certifications: UL listing (not just “recognized”), CE with test reports, IP68 from accredited labs, RoHS compliance, and ISO 9001. Industry-specific: ATEX for explosive areas, DNV-GL for marine, and FDA for food contact.

The Certification Decoder Ring:

| Certification | What It Really Means | Red Flags | How to Verify |

|---|---|---|---|

| UL Listed | Tested by Underwriters Labs | “UL Recognized” isn’t the same | Check UL database online |

| CE Marking | Meets EU standards | Self-declaration possible | Request test reports |

| IP68 | Dust-tight, submersible | “IP68 equivalent” = fake | Accredited lab certificate |

| ISO 9001 | Quality system audited | Easy to fake | Verify certification body |

| ATEX | Safe for explosive atmospheres | Critical for oil/gas | Notified body number |

The Top 10 Manufacturers: Who to Trust with Your Critical Connections

After 15 years of watching connectors fail (and succeed), here’s my battlefield-tested ranking:

1. TE Connectivity (Switzerland)

- Founded: 1941

- Specialty: DEUTSCH connectors that survive apocalypses

- Best For: Automotive, aerospace, battery storage systems

- Reality Check: Expensive but bulletproof

2. Amphenol (USA)

- Founded: 1932

- Specialty: Military-spec reliability

- Best For: Defense, marine, extreme environments

- Reality Check: 90,000 employees can’t be wrong

3. Fischer Connectors (Switzerland)

- Founded: 1954

- Specialty: Push-pull perfection, 20m depth testing

- Best For: Medical, military, subsea applications

- Reality Check: Swiss pricing for Swiss precision

4. Binder (Germany)

- Founded: 1960

- Specialty: Automation connectivity

- Best For: Factory automation, robotics

- Reality Check: German engineering at its finest

5. Anderson Power Products (USA)

- Founded: 1964

- Specialty: High-current monsters (120A+)

- Best For: Battery systems, power distribution

- Reality Check: 5,000 mating cycles guaranteed

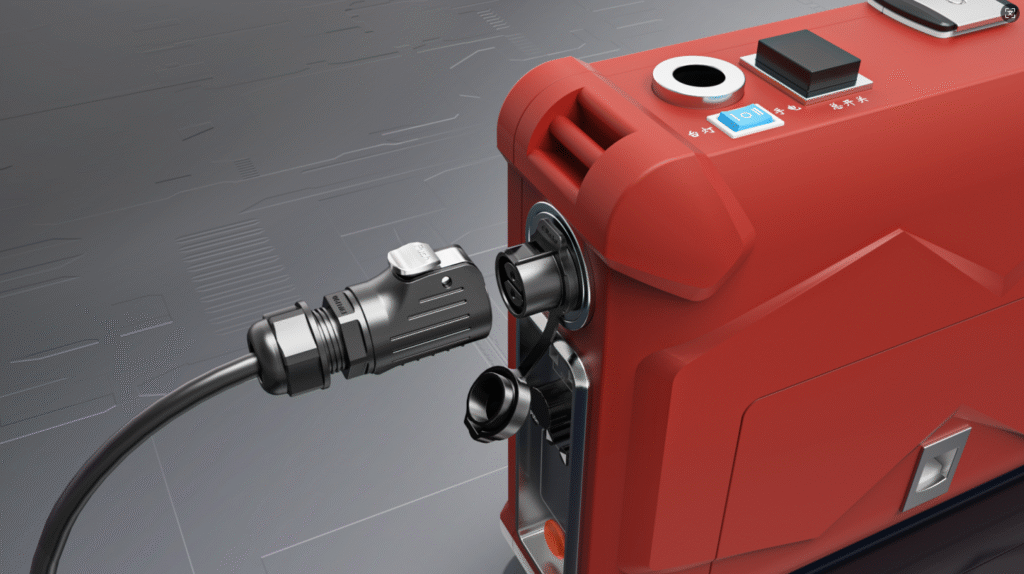

6. AGX (China)

- Founded: 2009

- Specialty: LP Series with triple-seal technology

- Best For: Solar, marine, industrial applications

- Reality Check: 15 years of fixing other brands’ failures

- Secret Weapon: Direct engineering support, not call centers

7. WEIPU (China)

- Founded: 1996

- Specialty: 2-200A range, 2-61 pin configurations

- Best For: Industrial machinery, LED lighting

- Reality Check: 28 years of steady improvement

8. KINSUN (Taiwan)

- Founded: 1986

- Specialty: Anti-UV champions

- Best For: Outdoor installations, automotive

- Reality Check: Taiwan quality control standards

9. Sunshine Connector (China)

- Founded: 2010

- Specialty: Screwless quick-connect design

- Best For: Field installations, LED systems

- Reality Check: Fast and affordable

10. Tekox (Spain)

- Founded: 1985

- Specialty: Tool-free installation

- Best For: Permanent installations

- Reality Check: European standards, competitive pricing

The AGX LP Series: What 15 Years of Failure Analysis Taught Us

Every horror story I’ve shared? We fixed those problems in our LP Series.

AGX LP Series Features:

- Triple-Seal Technology: Because water is patient and persistent

- 10,000+ Mating Cycles: Tested until our machines broke

- -40°C to +125°C: From Siberia to the Sahara

- 16A to 63A Options: Power when you need it

- 5-Year Warranty: Because we know they’ll last 20

Our LP Series survives where others surrender. North Sea oil rigs. Australian mines. Solar farms in the Mojave. We’ve seen them all, and we’ve built connectors that laugh at those conditions.

The Bottom Line: Your Next Steps

Stop buying connectors based on price alone. Stop trusting manufacturers who can’t show real test data. Stop replacing failed connections every few years.

Action Steps:

- Identify your true environmental conditions

- Request samples from 3-5 manufacturers

- Test them in YOUR conditions, not theirs

- Calculate the total cost, including downtime

- Choose reliability over initial savings

Remember: The bitterness of poor quality remains long after the sweetness of low price is forgotten.

Frequently Asked Questions

Q: How deep can IP68 connectors go?

A: Standard IP68 means “beyond 1 meter,” but serious manufacturers specify exact depths. Fischer tests to 20 meters, some specialty connectors survive 300 meters. Always verify the manufacturer’s specific rating.

Q: Are Chinese IP68 connectors as good as European ones?

A: Top-tier Chinese manufacturers like AGX, WEIPU, and KINSUN now match European quality. The key is choosing established companies with proper certifications, not random Alibaba suppliers.

Q: What’s the real difference between IP67 and IP68?

A: IP67 survives a 30-minute bath at 1 meter. IP68 lives underwater indefinitely at greater depths. For industrial applications, IP67 is asking for trouble.

Q: How often should IP68 connectors be replaced?

A: Quality IP68 connectors should last 10-20 years in normal conditions. If you’re replacing them every 2-3 years, you bought the wrong product.

Q: Can I upgrade from IP65 to IP68 connectors without rewiring?

A: Usually yes, if the cable diameter matches. Quality manufacturers like AGX offer retrofit solutions that use existing cable runs.

Ready to stop replacing failed connectors? Contact AGX for LP Series samples that actually survive your conditions. Because in the connector business, there’s no such thing as “good enough.”