Water damage ruins electrical systems. You need reliable connections that won’t fail. Waterproof electrical connectors effectively solve this critical problem.

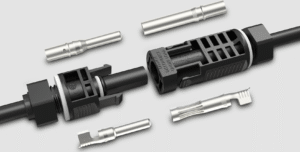

Waterproof electrical connectors are sealed connection devices that prevent water and moisture from entering electrical circuits. They use rubber gaskets, O-rings, and sealed housings to maintain IP65-IP68 protection ratings in harsh environments.

After 15 years in the waterproof connector industry, I’ve seen countless projects fail because people chose the wrong connectors. I’ve organized this comprehensive guide to help you better evaluate and select the right connectors. This guide provides value in cost savings, performance optimization, and installation success, helping you avoid expensive mistakes and achieve reliable long-term connections.

In the following sections, I’ll analyze waterproof connectors from four critical angles. First, I’ll reveal the essential design features that separate truly waterproof connectors from water-resistant imitations, saving you from costly seal failures. Second, I’ll decode IP rating specifications to help you match protection levels with your exact environmental requirements, preventing over-specification waste or under-protection risks. Third, I’ll compare connector types across different applications to optimize your selection for space, durability, and cost considerations. Finally, I’ll share the most common installation mistakes that cause even premium connectors to fail, ensuring your projects deliver long-term reliability.

We’ll also examine AGX Connector’s LP series industrial connectors with IP68 protection, demonstrating how proper engineering delivers superior performance in the most demanding applications.

What Makes a Connector Truly Waterproof?

Most people think any sealed connector is waterproof. They’re wrong. True waterproof performance requires specific design features that many connectors lack.

True waterproof connectors feature multiple sealing points, including cable entry seals, mating interface gaskets, and pressure-equalization systems. They must pass rigorous IP67 or IP68 testing standards for complete water immersion protection.

The key difference lies in the sealing system design. Standard connectors use single-point sealing that fails under pressure. Professional waterproof connectors employ multiple sealing barriers. The first barrier is the cable entry seal. This creates a watertight seal around each wire. The second barrier is the connector housing seal. This prevents water from entering the mating interface. The third barrier is the internal contact sealing. This protects the actual electrical connection points.

I learned this lesson early in my career when a client’s outdoor lighting system failed after one rainy season. The connectors looked waterproof but used cheap single-seal designs. Water infiltrated through microscopic gaps and corroded the connections. We replaced everything with proper multi-seal connectors and never had another failure.

The material selection matters just as much as the design. Quality waterproof connectors use specialized rubber compounds that remain flexible across temperature ranges. Cheap connectors use standard rubber that becomes brittle in cold weather and soft in heat. This creates seal failure and water intrusion.

How Do IP Ratings Work?

IP ratings confuse most buyers. You see numbers like IP65 and IP68, but don’t know what they mean for your specific application.

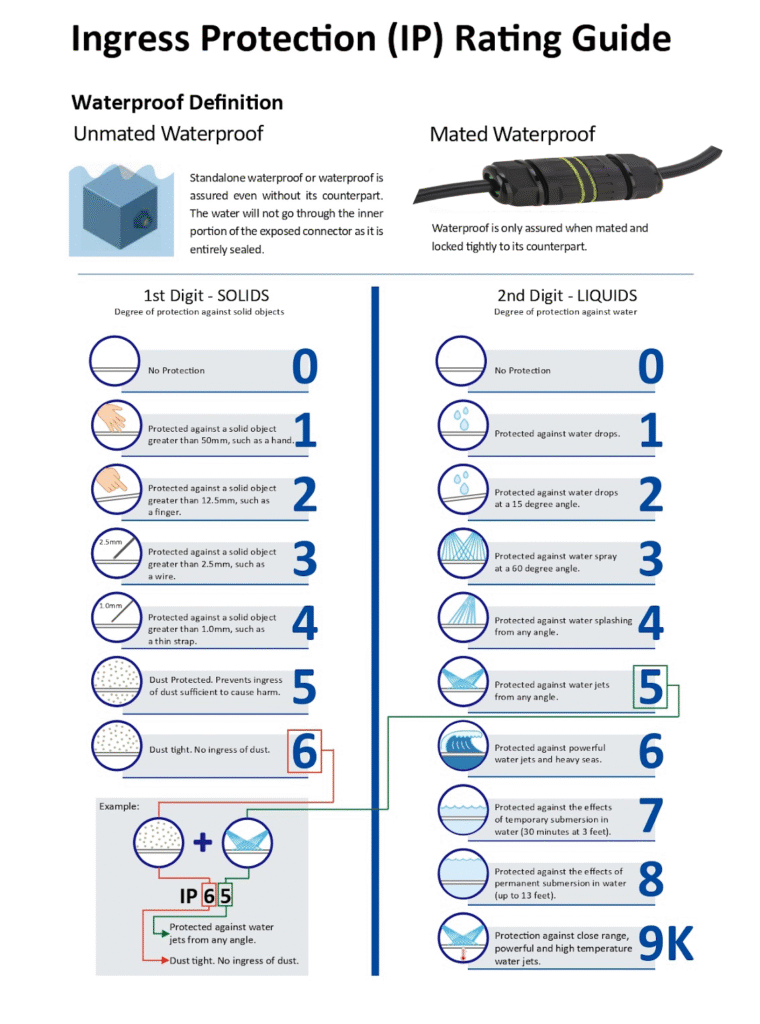

IP ratings use two digits to define protection levels. The first digit (0-6) indicates solid particle protection. The second digit (0-8) shows liquid protection. IP68 provides complete dust sealing and continuous water immersion protection.

Understanding IP ratings helps you choose the right connector for your environment. Many people assume higher numbers are always better. This isn’t true for every application. IP65 connectors resist water jets from any direction. This works perfectly for outdoor installations exposed to rain and washing. IP67 connectors survive temporary water immersion up to 1 meter deep. This suits applications near water sources or flood-prone areas.

IP68 connectors handle continuous underwater submersion. The manufacturer specifies the exact depth and duration limits. Some IP68 connectors work at 4 meters indefinitely. Others handle 10 meters for short periods. Always check the specific specifications rather than assuming all IP68 connectors perform identically.

Here’s what each rating means in practical terms:

| IP Rating | Dust Protection | Water Protection | Typical Applications |

|---|---|---|---|

| IP65 | Complete dust seal | Water jet resistant | Outdoor lighting, HVAC systems |

| IP67 | Complete dust seal | 1m immersion, 30min | Marine equipment, poolside installations |

| IP68 | Complete dust seal | Continuous submersion | Underwater lighting, submersible pumps |

The testing procedures reveal the real performance differences. IP65 testing uses 12.5mm nozzles spraying water at 30kN/m² pressure for 15 minutes from all angles. IP67 testing submerges the connector 1 meter deep for 30 minutes. IP68 testing varies by manufacturer but typically involves deeper submersion for longer periods.

Which Connector Types Work Best for Different Applications?

Choosing the wrong connector type costs time and money. Each connector family serves specific applications and environments better than others.

Circular connectors excel in harsh industrial environments. Rectangular connectors optimize space in control panels. Push-pull connectors enable quick connections in field applications. Each type offers distinct advantages for specific use cases.

Circular connectors dominate harsh environment applications because their round design distributes stress evenly. The threaded coupling mechanism creates reliable connections that won’t vibrate loose. I recommend circular connectors for heavy machinery, outdoor communications equipment, and marine applications. The main disadvantage is size. Circular connectors require more panel space than rectangular alternatives.

Rectangular connectors maximize contact density in limited space. Control panel applications benefit from rectangular designs because they mount flush against surfaces. The rectangular shape also simplifies cable management in tight spaces. However, rectangular connectors typically offer lower IP ratings than circular designs due to sealing challenges at the corners.

Push-pull connectors speed up field connections significantly. Traditional threaded connectors require multiple rotations to secure properly. Push-pull designs connect with a simple push and twist motion. This saves time during installation and maintenance. The trade-off is reduced vibration resistance compared to threaded alternatives.

Military-spec connectors handle the most extreme conditions but cost significantly more. MIL-DTL-38999 connectors survive temperature extremes, high vibration, and chemical exposure. Commercial applications rarely justify the expense unless operating conditions truly demand military-grade performance.

Here’s my recommendation matrix based on 15 years of field experience:

| Application Type | Recommended Connector | Key Advantage |

|---|---|---|

| Industrial automation | Circular M12/M8 | Vibration resistance |

| Control panels | Rectangular D-sub | Space efficiency |

| Field service | Push-pull circular | Quick connection |

| Harsh environments | Military circular | Extreme durability |

| Cost-sensitive | Sealed rectangular | Lower cost |

What Installation Mistakes Should You Avoid?

Perfect connectors fail when installed incorrectly. I’ve seen expensive waterproof connectors leak because installers skipped basic preparation steps.

Proper installation requires clean surfaces, correct torque specifications, and appropriate strain relief. Cable preparation, contact crimping, and seal inspection determine long-term reliability more than connector selection.

Cable preparation creates the foundation for reliable connections. Strip wire insulation to exact specifications. Too little stripping prevents proper contact engagement. Too much stripping exposes bare wire that corrodes over time. Use proper stripping tools rather than utility knives that nick conductor strands.

Contact crimping requires the right tool and technique. Hand crimpers work for small quantities but produce inconsistent results. Pneumatic crimpers deliver repeatable compression force. The crimp quality directly affects connection resistance and long-term reliability. A poor crimp creates heat buildup that degrades the connector over time.

Torque specifications exist for good reasons. Under-torquing allows water infiltration through loose seals. Over-torquing deforms seals and creates leak paths. Use calibrated torque wrenches rather than estimating by feel. Record torque values for quality control documentation.

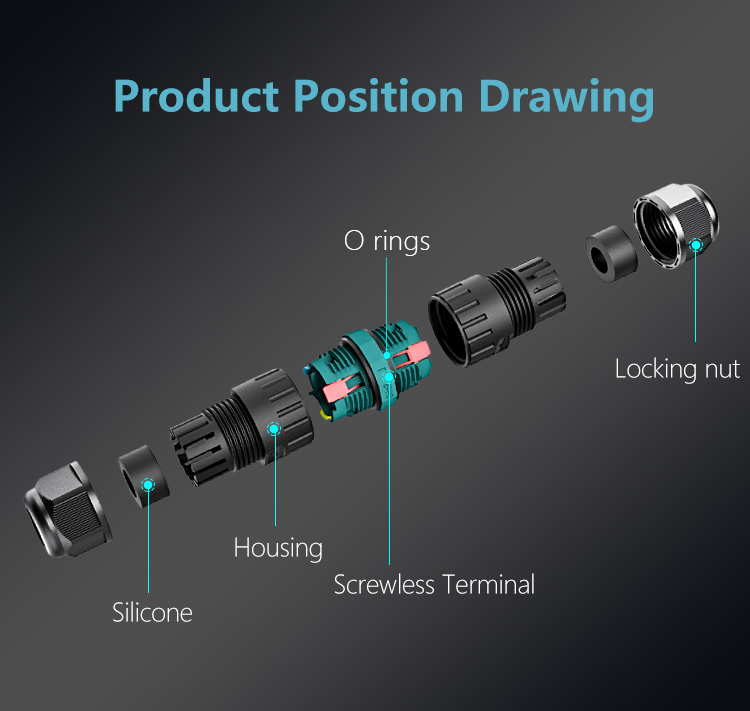

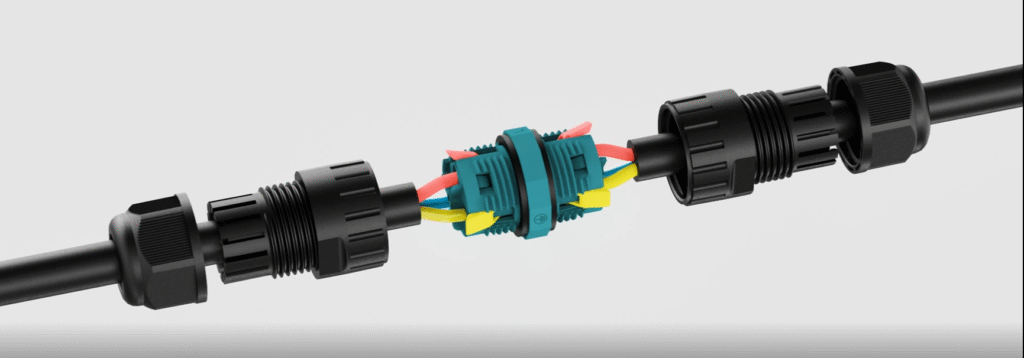

Strain relief prevents cable movement from damaging internal connections. Route cables with gentle curves rather than sharp bends. Secure cables within 6 inches of the connector to prevent stress concentration. Use proper cable glands that match the cable diameter exactly.

Environmental sealing requires attention to detail that many installers overlook. Apply thread-locking compound to threaded connections exposed to vibration. Use silicone grease on O-rings to ensure proper seating. Inspect seals for cuts, nicks, or contamination before assembly.

AGX Connector LP Series: Industrial IP68 Excellence

After comparing numerous connector options, I would like to highlight our AGX Connector LP series as a prime example of proper waterproof engineering. These industrial connectors achieve true IP68 protection through advanced design features.

The AGX LP series features a PBT plastic housing combined with zinc alloy components and gold-plated contacts. This robust construction delivers reliable performance in underwater applications up to 2 meters depth for industrial machinery connections.

Our LP series demonstrates every principle discussed in this guide. The connector housing uses high-grade PBT plastic material combined with zinc alloy reinforcement for an optimal strength-to-weight ratio. Each contact receives gold plating to prevent oxidation and ensure long-term conductivity. The cable entry system features precision-engineered seals that maintain IP68 protection even under mechanical stress.

The LP series excels in demanding industrial applications. We’ve successfully deployed these connectors in large machinery systems, robotic arms, mining equipment mainframes, industrial robots, and medical devices. The robust construction handles the vibration, temperature cycling, and environmental exposure common in these applications.

Real-world performance validates our engineering approach. Mining equipment operators report zero connector failures after 18 months of continuous underground operation. Medical device manufacturers choose LP series for critical patient monitoring systems where reliability cannot be compromised. Robotics integrators depend on LP series connections for precise control signals in automated production lines.

What sets the AGX LP series apart is our focus on industrial-grade reliability. We don’t just sell connectors – we engineer solutions for specific industrial challenges. Our technical team understands the unique requirements of heavy machinery, robotics, and medical applications, helping you specify the right connector configuration for maximum uptime and safety.

Conclusion

This comprehensive guide revealed how proper connector selection, IP rating understanding, type matching, and installation techniques prevent costly electrical failures. These insights help you specify reliable waterproof connections that protect your investments and ensure long-term performance.

At AGX Connector, we’re committed to making electrical connections safer and more convenient through superior engineering and expert guidance. Our 15 years of industry experience help you navigate complex connector decisions with confidence.

Ready to upgrade your waterproof connections? Contact our technical team at AGX Connector for personalized application support and reliable LP series solutions that deliver proven performance in the harshest environments.