When I started in this industry 15 years ago, I learned the hard way that not all waterproof connectors are created equal. Poor quality standards can cost you thousands in failed projects.

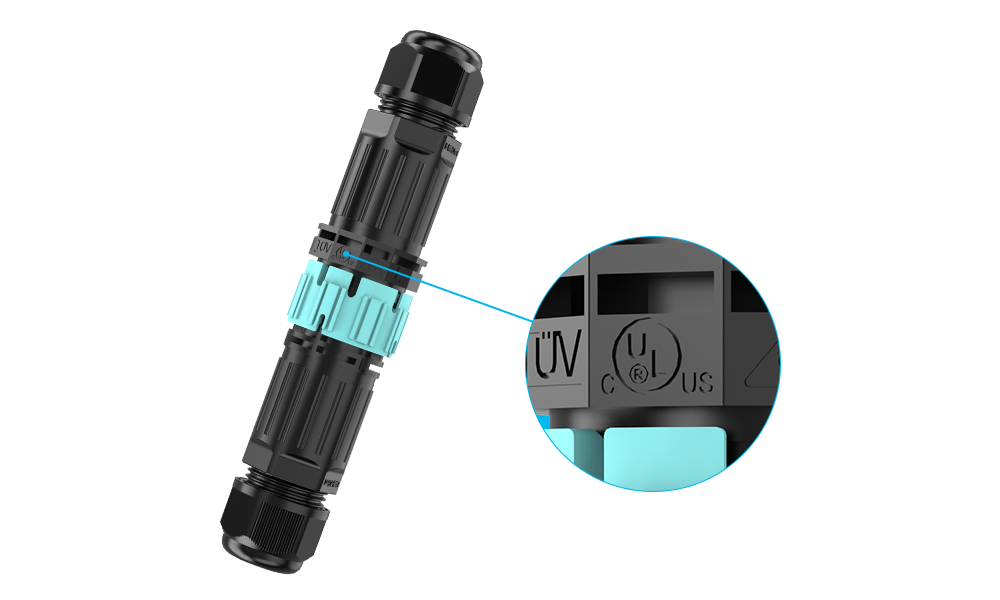

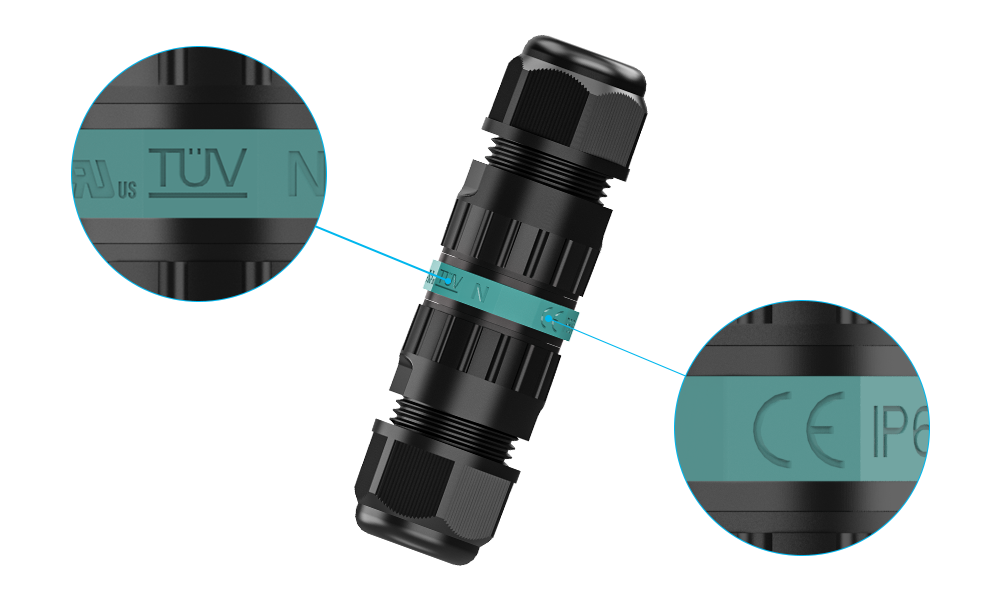

The most important quality standards for waterproof connector manufacturers include IP ratings, UL certifications, CE marking, TÜV certifications, RoHS compliance, and ISO 9001 compliance. These certifications ensure your connectors meet safety, performance, and reliability requirements for critical applications.

So I’ve organized this comprehensive guide to help you better evaluate and find the right connector suppliers. This knowledge will add value in three key areas: reducing project risks through proper certification verification, avoiding costly compliance issues in different markets, and building stronger supplier relationships based on quality standards understanding.

In the following sections, I’ll walk you through ✅ the critical importance of IP ratings for real-world waterproof performance, ✅ how UL certifications protect your business from liability and compliance issues, ✅ what CE marking means for accessing European markets, ✅ how ISO quality management standards ensure consistent product reliability, ✅ why TÜV certifications open doors in German-speaking markets, and ✅ how RoHS compliance affects your entire supply chain strategy. Each section provides practical insights to help you make informed supplier decisions and avoid costly mistakes.

After years of working with distributors like Jacky in Spain, I’ve seen how the right certifications can make or break a business relationship. Let me share what matters when choosing a manufacturer.

Why Do IP Ratings Matter More Than You Think?

I remember when a customer called me panicking because their outdoor lighting system failed after one rainy season. They bought connectors without proper IP ratings.

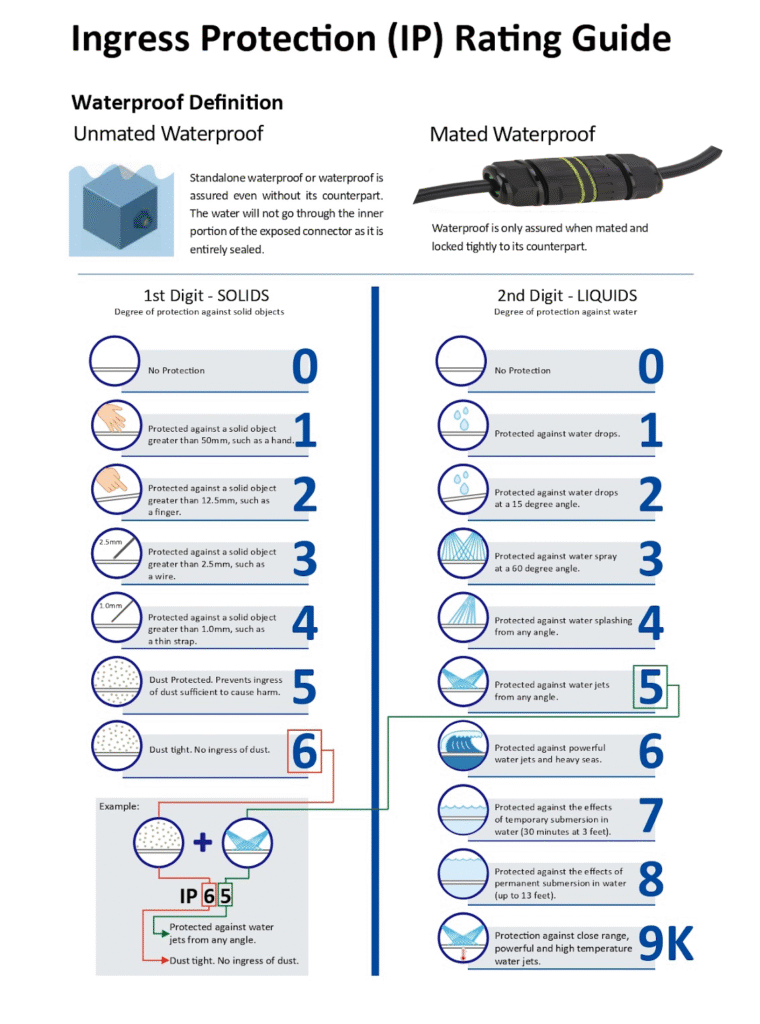

IP (Ingress Protection) ratings measure how well a connector blocks dust and water. For outdoor use, you need at least an IP67 rating, which means complete dust protection and submersion resistance up to 1 meter for 30 minutes.

The IP rating system uses two numbers. The first digit shows dust protection from 0 to 6. The second digit shows water protection from 0 to 9. In my factory, we test every batch to ensure it meets the claimed IP rating.

Here’s what each common IP rating means for real-world use:

| IP Rating | Dust Protection | Water Protection | Best Applications |

|---|---|---|---|

| IP65 | Complete dust seal | Water jets from any direction | Indoor industrial equipment |

| IP67 | Complete dust seal | Temporary submersion up to 1m | Outdoor lighting, marine equipment |

| IP68 | Complete dust seal | Continuous submersion beyond 1m | Underwater applications, harsh environments |

When I visit trade shows, the customers always ask manufacturers how they test their IP ratings. Many can’t give you a straight answer. At AGX, we use pressure chambers and submersion tanks. We also age-test our seals because rubber degrades over time.

The testing process takes weeks, not days. We cycle connectors through temperature changes while maintaining water pressure. This simulates years of outdoor use in just a few weeks. I learned this approach from a German engineer who taught me that quick tests don’t reveal long-term failures.

How Do UL Certifications Protect Your Business Investment?

Three years ago, a distributor in Texas almost lost a major contract because their connectors lacked UL certification. The electrical inspector wouldn’t approve the installation without it.

UL (Underwriters Laboratories) certification proves that connectors meet North American safety standards. UL 1977 specifically covers industrial connectors, while UL 4128 covers energy storage connectors, and UL 2238 covers low-voltage landscape lighting connectors.

Getting UL certification isn’t easy or cheap. The process takes 6-12 months and costs tens of thousands of dollars. UL engineers visit our factory to inspect our quality systems. They test samples under extreme conditions, including fire, electrical overload, and mechanical stress. UL also charges quarterly fees for ongoing certification maintenance.

The testing requirements vary by connector type and application:

Electrical Safety Tests:

- Dielectric strength testing at 1500V AC

- Insulation resistance measurements

- Temperature rise testing under maximum current

- Short circuit protection verification

Mechanical Tests:

- Insertion and withdrawal force measurements

- Vibration testing for automotive applications

- Thermal cycling from -40°C to +85°C

- UV resistance testing for outdoor use

Environmental Tests:

- Salt spray corrosion testing

- Humidity cycling

- Chemical resistance testing

- Flame spread and smoke generation

I always tell my customers that UL certification costs more upfront but saves money long-term. Insurance companies often require UL-listed components. Building inspectors won’t approve installations without proper certifications. One failed inspection can cost more than buying certified connectors from the start.

What Does CE Marking Mean for European Markets?

When Jacky first contacted me about supplying connectors for Spanish projects, he emphasized that CE marking wasn’t optional. European regulations are strict, and penalties for non-compliance are severe.

CE marking indicates that waterproof connectors comply with European health, safety, and environmental protection standards. The Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive are most relevant for electrical connectors.

%(image placeholder)CE marking requirements for waterproof connectors

The CE marking process involves several steps that many manufacturers try to shortcut. First, you must identify which European directives apply to your product. For waterproof connectors, this usually includes LVD 2014/35/EU for electrical safety and EMC 2014/30/EU for electromagnetic compatibility.

Technical Documentation Requirements:

- Detailed product specifications and drawings

- Risk assessment and safety analysis

- Test reports from accredited laboratories

- Declaration of Conformity signed by an authorized representative

- User manuals in local languages

Testing Standards for CE Compliance:

- EN 61984 for connector safety requirements

- EN 55015 for electromagnetic emission limits

- EN 61547 for electromagnetic immunity requirements

- EN 60529 for IP rating verification

The biggest mistake I see manufacturers make is self-declaring CE compliance without proper testing. European authorities conduct market surveillance. If they find non-compliant products, penalties include product recalls, fines, and import bans.

I learned this lesson early when customs officials in Germany seized a shipment because our documentation was incomplete. We had the right test reports, but hadn’t appointed an authorized representative in the EU. This simple oversight cost us three weeks and thousands in storage fees.

Working with a European authorized representative is crucial. They handle communications with authorities and maintain technical documentation. Choose someone with experience in electrical components, not just any legal service.

How Do ISO Quality Management Standards Impact Product Consistency?

During my early years as a salesperson, I visited many factories claiming to have quality systems. Most were just paperwork exercises. Real ISO implementation changes how you think about manufacturing.

ISO 9001 is the foundation quality management standard that ensures consistent processes and continuous improvement. For waterproof connector manufacturers, additional standards like ISO 14001 for environmental management, ISO 13485 for medical devices, and IATF 16949 for automotive applications provide specialized quality frameworks.

When we implemented our ISO certifications at AGX, the biggest change was documentation. Every process needed written procedures. Every employee needed training records. Every customer complaint needed analysis and corrective action.

Key ISO Standards for Connector Manufacturers:

| ISO Standard | Focus Area | Best For | Requirements |

|---|---|---|---|

| ISO 9001 | Quality Management | All manufacturers | Risk management, design controls, and post-market surveillance |

| ISO 14001 | Environmental Management | Export markets | Environmental policy, waste reduction, compliance tracking |

| ISO 13485 | Medical Device Quality | Medical connectors | Advanced quality planning, statistical process control, and supplier development |

| IATF 16949 | Automotive Quality | Automotive connectors | Advanced quality planning, statistical process control, supplier development |

ISO 9001 – Foundation Requirements:

- Management commitment and leadership

- Risk-based thinking in planning

- Customer focus and satisfaction measurement

- Process approach to operations

- Evidence-based decision making

- Continuous improvement culture

ISO 14001 – Environmental Management: I learned that many European customers now require ISO 14001 certification. They want suppliers who actively manage environmental impact. This standard requires us to track energy consumption, waste generation, and chemical usage. We set annual environmental targets and measure progress monthly.

ISO 13485 – Medical Device Quality: For medical applications, ISO 13485 goes beyond ISO 9001. It requires risk management throughout the product lifecycle. We must validate that our connectors won’t fail in life-critical situations. The documentation burden is significant – every design decision needs justification and approval.

IATF 16949 – Automotive Quality: Automotive customers demand IATF 16949 certification. This standard requires statistical process control for every manufacturing step. We monitor key characteristics with control charts and stop production if processes drift. Supplier development is also mandatory – we must help our suppliers improve their quality systems.

The audit process happens annually with surveillance visits every six months. Auditors review our processes, interview employees, and examine records. They look for evidence that we follow our documented procedures.

Documentation We Maintain:

- Quality manual describing our quality system

- Process procedures for each manufacturing step

- Work instructions for operators

- Inspection and test procedures

- Calibration records for measuring equipment

- Training records for all personnel

- Customer feedback and complaint handling

- Supplier evaluation and monitoring

- Internal audit reports and corrective actions

The real benefit comes from the mindset change. Before ISO 9001, we fixed problems after they happened. Now we prevent problems through process control and continuous monitoring.

Our production manager and quality manager track key metrics monthly: defect rates, customer complaints, delivery performance, and employee suggestions. This data drives our improvement projects. Last year, we reduced connector failure rates by 20% through better seal design based on field failure analysis.

Why Are TÜV SÜD and TÜV Rheinland Certifications Worth the Investment?

Last month, a customer from Munich specifically requested TÜV certification for their industrial project. German engineers trust TÜV more than any other certification body, and I quickly understood why.

TÜV SÜD and TÜV Rheinland are German testing organizations that provide independent safety certification for electrical products. Their certifications are highly respected in Europe and are often required for critical industrial applications.

The difference between TÜV and other certification bodies lies in their testing thoroughness. When TÜV engineers visited our factory, they spent three days examining every detail of our production process. They didn’t just test samples – they observed how we manufactured them.

TÜV SÜD vs TÜV Rheinland – What’s the Difference:

| Aspect | TÜV SÜD | TÜV Rheinland |

|---|---|---|

| Founded | 1866 in Munich | 1872 in Cologne |

| Global Presence | 1,000+ locations worldwide | 500+ locations in 69 countries |

| Specialty Focus | Automotive, industrial safety | Electronics, renewable energy |

| Testing Standards | DIN VDE, IEC, EN standards | Same standards, different approach |

| Market Recognition | Strong in Southern Germany | Strong in Northern Europe |

Both organizations follow the same technical standards but have different testing philosophies. TÜV SÜD focuses more on long-term reliability testing. They run connectors through extended thermal cycling – sometimes 10,000 cycles compared to the standard 1,000 cycles. TÜV Rheinland emphasizes electrical safety testing with more rigorous dielectric strength tests.

The certification process takes 8-12 weeks longer than standard CE testing. TÜV engineers require detailed material specifications, including the molecular composition of rubber seals. They test aging characteristics under accelerated conditions. This means exposing connectors to UV radiation equivalent to 20 years of sunlight in just 2,000 hours.

I always recommend TÜV certification for customers in Germany, Austria, and Switzerland. Engineers in these countries grew up trusting TÜV marks. It opens doors that other certifications can’t. The premium price – usually 15-20% higher – pays for itself through increased sales and fewer technical questions.

How Does RoHS Compliance Affect Your Supply Chain?

Two years ago, European customs rejected an entire shipment of our connectors because one small component contained restricted lead solder. That expensive lesson taught me never to underestimate RoHS requirements.

RoHS (Restriction of Hazardous Substances) limits six dangerous materials in electrical products: lead, mercury, cadmium, hexavalent chromium, and two types of brominated flame retardants. All waterproof connectors sold in Europe must comply with the RoHS 3 directive.

RoHS compliance goes deeper than many manufacturers realize. It’s not enough to test the final product. You must control every component and raw material throughout your supply chain. At AGX, we audit our suppliers quarterly and require RoHS certificates for every material batch.

The Six Restricted Substances and Their Limits:

- Lead (Pb): Maximum 1000 ppm (0.1%)

- Mercury (Hg): Maximum 1000 ppm (0.1%)

- Cadmium (Cd): Maximum 100 ppm (0.01%)

- Hexavalent Chromium (Cr6+): Maximum 1000 ppm (0.1%)

- PBB (Polybrominated biphenyls): Maximum 1000 ppm (0.1%)

- PBDE (Polybrominated diphenyl ethers): Maximum 1000 ppm (0.1%)

Testing for RoHS compliance requires X-ray fluorescence (XRF) screening followed by chemical analysis for positive results. We test every material: copper conductors, plastic housings, rubber seals, metal contacts, and even the smallest screws. A single non-compliant component makes the entire connector illegal in Europe.

Common RoHS Compliance Challenges:

- Lead in older brass alloys used for contacts

- Cadmium in zinc-plated hardware

- Hexavalent chromium in metal surface treatments

- Brominated flame retardants in cable jackets

- Mercury in certain plastic stabilizers

The documentation burden is significant. We maintain a complete Bill of Materials (BOM) for every connector model. Each component needs a supplier declaration, test certificate, and change control procedure. When suppliers modify their processes, we must re-test and update our records.

RoHS 3 also introduced new requirements for medical devices and industrial monitoring equipment. These categories were previously exempt but now must comply. The transition period ended in 2021, so all new products must meet RoHS 3 requirements.

I learned that different countries interpret RoHS differently. While the EU directive sets minimum standards, countries like Norway and Turkey have stricter requirements. Always check local regulations before entering new markets.

Working with accredited RoHS testing laboratories is essential. We use labs certified to the ISO 17025 standard for accurate results. Cheap testing often produces false negatives that cause problems later. The cost of proper RoHS testing – typically $200-500 per connector model – is minimal compared to the cost of product recalls or import bans.

Conclusion

Understanding these quality standards and certifications isn’t just about technical compliance – it’s about protecting your business, accessing global markets, and building lasting partnerships with reliable suppliers. Throughout this guide, I’ve shared real experiences from 15 years in the waterproof connector industry to help you avoid costly mistakes and make informed decisions. From IP rating testing that prevents field failures to RoHS compliance that keeps your products in European markets, each certification serves a critical business purpose. At AGX, we’re committed to making electrical connections safer and more convenient through rigorous quality standards. When you choose suppliers who truly understand and implement these certifications, you’re not just buying connectors – you’re investing in your project’s success and your company’s reputation.